Method for preparing organic fertilizer by taking wet garbage as raw material

A technology for organic fertilizers and garbage, applied in the directions of organic fertilizers, fertilization devices, liquid fertilizers, etc., can solve the problems of long production cycle, high production cost, low processing efficiency, etc., and achieve short reaction time, low production cost, and high processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

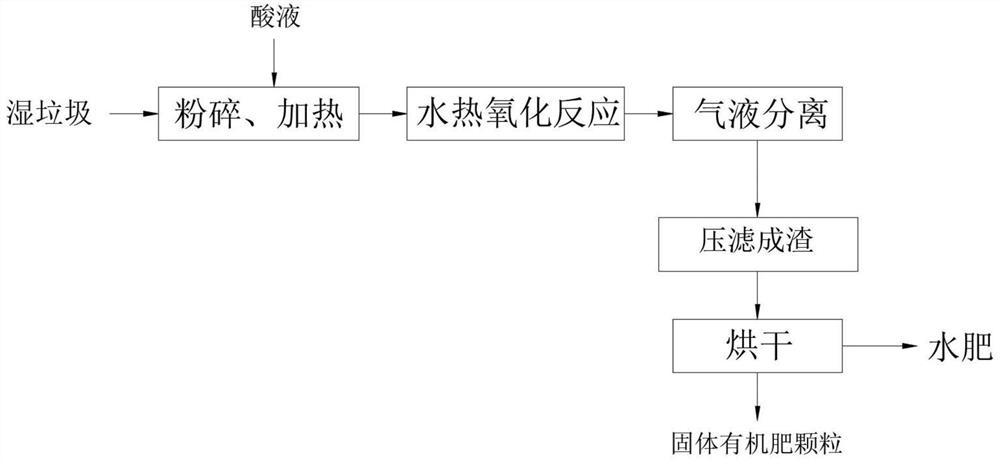

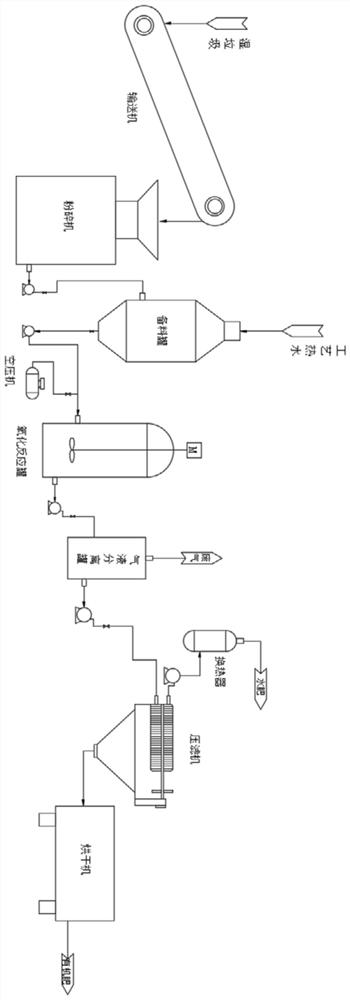

[0034] see Figure 1~2 , in the embodiment of the present invention, a kind of organic fertilizer preparation method using wet waste as raw material, preparation method comprises the following steps:

[0035] S1. The wet garbage is sent to the shredder through the belt conveyor for crushing. The crushed garbage is pumped to the material preparation tank, and process hot water is added to the material preparation tank. After mixing and stirring, the temperature is raised to 70-80°C. form a slurry;

[0036] S2. Pump the slurry into the oxidation reaction tank, and heat the slurry in the oxidation reaction tank. The high temperature can speed up the transfer of oxygen and reduce the viscosity of the liquid. At the same time, inject it into the oxidation reaction tank through an air compressor Compress the air, then add acid liquid into the oxidation reaction tank, and continue to stir to carry out the oxidation reaction, so that the organic matter in the wet garbage decomposes h...

Embodiment

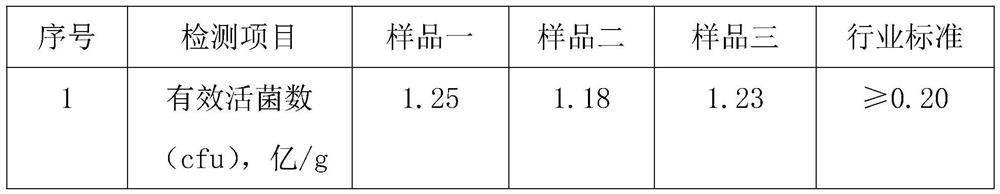

[0058] Example: Take 10 samples of solid organic fertilizer granules at different positions by random method, take 300-500g of samples from each sample under sterile conditions, then mix all the samples, and divide into 3 parts according to the quartering method , each not less than 500g, test 3 samples respectively, and detect the effective number of viable bacteria (cfu), organic matter content, water content, pH value, fecal coliform number, roundworm egg death number, arsenic content (As ), cadmium content (Cd), lead content (Pb), chromium content (Cr) and mercury content (Hg), the experimental data are as follows:

[0059] Table 1: The results of the content of each component:

[0060]

[0061]

[0062] The industry standard is the Agricultural Industry Standard of the People's Republic of China NY 884——2012 Microbial Organic Fertilizer (Microbial Organic Fertilizer) 2012-06-06 release 2012-09-01 implementation

[0063] From Table 1, it can be concluded that the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com