Patents

Literature

30 results about "N-butyl vinyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold-rolling steel-plate punch drawing lube oil and its production

InactiveCN101029272AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherParaffin oils

A cold-rolling steel-plate punch stretch lube oil consists of motor oil 45-55wt%, castor oil 6-10wt%, soya oil 8-12wt%, barium mahogany acid 1-3wt%, lead naphthenate 1-3wt%, chlorinated paraffin 10-20wt%, butyl-octanol zinc salt phosphinothioyl 4-6wt% and poly-n-butyl vinyl ether 6-10wt% and bactericide 0.2-0.3wt%. The process is carried out by adding motor oil into reactor, heating to 90-100degree, adding into barium mahogany acid, lead naphthenate and chlorinated paraffin, agitating at 750-850 / min for 1.5-2.5hrs, lowering temperature to 50-60degree, adding into castor oil, soya oil and bactericide, agitating for 0.5-1.5hrs, lowering to normal temperature, adding into butyl-octanol zinc salt phosphinothioyl and poly-n-butyl vinyl ether and agitating at 85-95 / min for 1.5-2.5hrs. It has better oil-film continuity and adsorption and prevents punch work-piece from being scraped and corrosion.

Owner:DALIAN SANDAAOKE CHEM

Zinc-coated steel-plated punch drawing lube oil and its production

InactiveCN101029271AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherParaffin oils

A galvanized steel plate punch stretch lube oil consists of motor oil 45-55wt%, castor oil 2-4wt%, soya oil 25-35wt%, mersolates 0.5-1.5wt%, zinc naphthenate 0.5-1.5wt%, triethyl phosphate 2-4wt%, chlorinated paraffin 3-5wt%, butyl-octanol zinc salt phosphinothioyl 2-4wt%, poly-n-butyl vinyl ether 4-6wt% and bactericide 0.2-0.3wt%. The process is carried out by adding motor oil into reactor, heating to 90-100degree, agitating at 750-850 / min, adding into mersolates, zinc naphthenate, chlorinated paraffin and triethyl phosphate successively, agitating for 1.5-2.5hrs, lowering temperature to 50-60degree, adding into castor oil, soya oil and bactericide, agitating for 0.5-1.5hrs, lowering to normal temperature, adding into butyl-octanol zinc salt phosphinothioyl and poly-n-butyl vinyl ether, and agitating at 75-85 / min and agitating 1.5-2.5hrs. It has better oil-film continuity and adsorption and prevents punch work-piece from being scraped and corrosion.

Owner:DALIAN SANDAAOKE CHEM

Lubricating oil for stamping and stretching stainless steel plate and production method

InactiveCN102585981AWill not cause sticking to the moldPrevents chafing and wearLubricant compositionTert butyl phenolN-butyl vinyl ether

The invention discloses lubricating oil for stamping and stretching a stainless steel plate and a production method. The raw materials are as follows, by mass percentage, 1-6% of chlorcosane, 4-14% of dibutyl phosphite, 1-12% of sulphurized sperm oil, 0.1-1.0% of 2,6-di-tert-butyl phenol, 1-6% of polybutyl vinyl ether, 1-5% of lead naphthenate, 1-16% of oleic acid triethanolamine (1:1.5), 0.1-1.0% of simethicone, 10-30% of transformer oil and the balance machine oil. The production method includes adding the machine oil and the transformer oil into a reaction kettle, heating to 48 to 52 DEG C, starting a blender with rotary speed of 60 turns / minute, adding chlorcosane, dibutyl phosphite, sulphurized sperm oil, lead naphthenate, oleic acid triethanolamine (1:1.5), 2,6-di-tert-butyl phenol, polybutyl vinyl ether, polybutyl vinyl ether and simethicone which are calculated and weighed sequentially into the reaction kettle, stirring for 2-3 hours continuously, dissolving, cooling to room temperature, discharging and packaging.

Owner:DALIAN SANDAAOKE CHEM

Modified transformer oil with excellent insulation strength and preparation method thereof

InactiveCN106635330AHigh dielectric strengthIncrease dosageAdditivesN-butyl vinyl etherBoron carbide

The invention discloses modified transformer oil with excellent insulation strength. The modified transformer oil is prepared from the following raw materials: naphthenic base oil, modified nano-titanium dioxide, 2,6-butylated hydroxytoluene, 2-(2'-hydroxy-5'-methylphenyl) benzotriazole, benzotriazole, n-dodecylbenzene, zinc acetylacetonate, polyimide, ethanediamine, a ultraviolet absorbent UV-P, poly(vinyl butyl ether), dibutyl phthalate, an antioxidant, a silane coupler KH-560, boron carbide, silicon nitride, copper powder, methyl acrylate, polyethylenesulphonate, stearic acid and pentaerythritol. The invention further provides a method for preparing the modified transformer oil with excellent insulation strength. The modified transformer oil prepared by the method has excellent insulation strength.

Owner:马光德

Drawing lube cooling oil of aluminum-coated red copper metal bar and its production

InactiveCN101029266AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherOleic Acid Triglyceride

A dual-metal rod pulling lube cooling oil of copper aluminum-coated consists of motor oil 20-30wt%, oleic acid 8-9wt%, tritolyl phosphate 20-30wt%, benamide azole trinitride 0.8-0.9wt%, anhydrous alcohol 1-2wt%, sulfur-phosphorus butanoctyl-zinc salt 20-30wt%, poly-n-butyl vinyl ether 13.5-14.5wt% and bactericide 0.2-0.3wt%. The process is carried out by dissolving benamide azole trinitride by anhydrous alcohol, adding motor oil into reactor, heating to 80-90degree, adding into tritolyl phosphate and oleic acid successively, agitating at 550-650 / min for 0.5-1.5hrs, lowering temperature to 40-50degree, adding benamide azole trinitride ethanol solution and bactericide into mixed solution, agitating for 0.5-1.5hrs, cooling, adding into sulfur-phosphorus butanoctyl-zinc salt and poly-n-butyl vinyl ether successively and agitating at 25-35 / min for 0.5-1.5hrs. It has excellent finish degree and brightness.

Owner:DALIAN SANDAAOKE CHEM

High-speed drawing lubricating cooling oil of nickel-chromium stainless steel

InactiveCN101029270AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherChlorinated paraffins

A high-speed pulling lube cooling oil of nickel-chromium stainless steel wire consists of oleic acid 4-6wt%, motor oil 20-30wt%, castor oil 8-12wt%, chlorinated paraffin 30-40wt%, mersolates 4-6wt%, aluminum naphthenate 4-6wt%, phosphinothioyl buoctyl-zinc salt 8-12wt%, poly-n-butyl vinyl ether 4-6wt% and bactericide 0.1-0.2wt%. The process is carried out by adding motor oil and chlorinated paraffin into reactor successively, heating to 70-80degree, agitating at 480-500 / min, adding into mersolates, aluminum naphthenate, oleic acid and bactericide, agitating for 0.5-1.5hrs, lowering temperature to normal temperature, adding into phosphinothioyl buoctyl-zinc salt and poly-n-butyl vinyl ether and agitating at 30-40 / min for 1-3hrs. It can prevent pulling metal from overheat and oxidation coloring and have better finish degree and brightness.

Owner:DALIAN SANDAAOKE CHEM

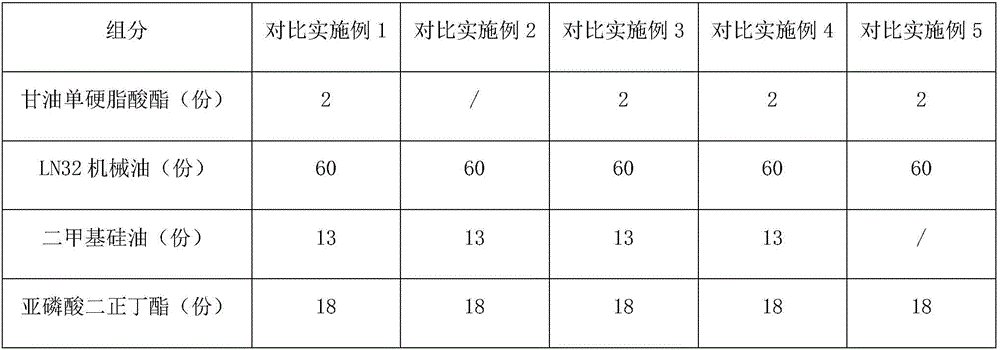

Stainless steel stamping tension lubricating oil

InactiveCN103756763AImprove the lubrication effectImprove cooling effectLubricant compositionPhosphorous acidTert butyl phenol

The invention discloses a stainless steel stamping tension lubricating oil which comprises the following components in parts by mass: 1-2 parts of glycerin monostearate, 55 parts of LN32 mechanical oil, 8 parts of chlorinated paraffin, 4 parts of dimethyl silicon oil, 19 parts of phosphorous acid di-n-butyl phosphate, 8 parts of lead naphthenate, 23 parts of triethanolamine oleate, 9 parts of poly(n-butyl) vinyl ether, 35 parts of transformer oil, 17 parts of vulcanized whale oil, 2 parts of 2.6-di-tert-butyl phenol and 1 part of hydroxypropyl methyl cellulose. The stainless steel stamping tension lubricating oil is good in lubrication and cooling property and easy to demold, and is capable of preventing a stamped surface from scratch or rusting, ensuring surface smoothness and cleanness, and meeting the direct assembling requirements.

Owner:CHANGSHU MEIERTE METAL PROD

High-viscosity water-based rust-proof and anti-flame hydraulic oil and preparation technology thereof

The invention discloses a high-viscosity water-based rust-proof and anti-flame hydraulic oil and a preparation technology thereof. The high-viscosity water-based rust-proof and anti-flame hydraulic oil comprises a, b and c constituents, and the mass ratio of the a, b and c constituents is 1:1.5:2. The a constituent comprises an A constituent and a B constituent, wherein the A constituent comprises the following constituents in parts by weight: one part of sodium dodecyl benzene sulfonate, 4 parts of monopotassium phosphate, 3 parts of sulfurized calcium alkyl phenolate, 26 parts of sodium citrate, 16 parts of polyacrylamide and 15 parts of nanometer borate; and the B constituent comprises 8 parts of polyacrylamide, 9 parts of phosphoric acid, 11 parts of polysorbate, 12 parts of glycerine, 16 parts of polyethylene glycol and 15 parts of monopotassium phosphate. The b constituent comprises 31 parts of sulfurized isobutylene, 18 parts of epoxidized vegetable oil, 24 parts of lupeol palmitate, 16 parts of poly-n-butyl vinyl ether and 11 parts of polymethacrylate. The hydraulic oil is green and environmentally-friendly; the production process is safe; meanwhile, the constituent ratio is stable; and the prepared water-based rust-proof and anti-flame hydraulic oil has excellent anti-flame performance, lubricating performance and anti-rust property.

Owner:SUZHOU JIN YUAN OIL MACHINERY

Thick-wall bearing steel pipe drawing lubricating emulsifying oil and production method thereof

InactiveCN102585978AImprove adsorption capacityReduce wearLubricant compositionN-butyl vinyl etherTriethylamine phosphate

The invention discloses thick-wall bearing steel pipe drawing lubricating emulsifying oil, which consists of the following raw material components in percentage by mass: 1-15 percent of oleic acid, 1-8 percent of barium mahogany sulfonate, 1-8 percent of lead naphthenate, 10-20 percent of chlorinated paraffin, 10-20 percent of 2,6-butylated hydroxytoluene, 1-4 percent of triethyl phosphate, 1-4 percent of dibutyl phthalate, 1-6 percent of zinc dialkyl dithiophosphate, 1-6 percent of polyvinyl butyl ether and the balance transformer oil. A production method of the emulsifying oil comprises the following steps of: adding the transformer oil into a reaction kettle, and heating to 40-50 DEG C; starting a stirrer and controlling the rotating speed at 40 revolutions per minute; slowly and sequentially adding barium mahogany sulfonate, lead naphthenate, oleic acid, chlorinated paraffin, triethyl phosphate, dibutyl phthalate, T501, T202 and T601 into the reaction kettle, wherein a next raw material is added till a previous raw material is fully dissolved by stirring; after all raw materials are dissolved, continually stirring for 1 hour; and discharging and packaging.

Owner:DALIAN SANDAAOKE CHEM

Aluminum film water system photoresistance stripping liquid in liquid crystal panel manufacture technology and preparation method thereof

InactiveCN104932211AImproved photoresist stripping performanceAvoid damagePhotosensitive material processingManufacturing technologyN-butyl vinyl ether

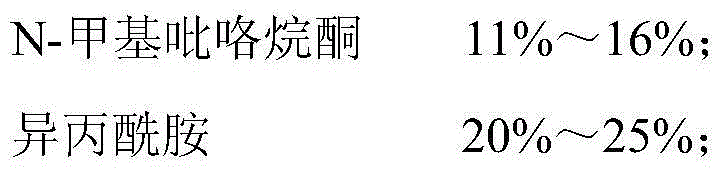

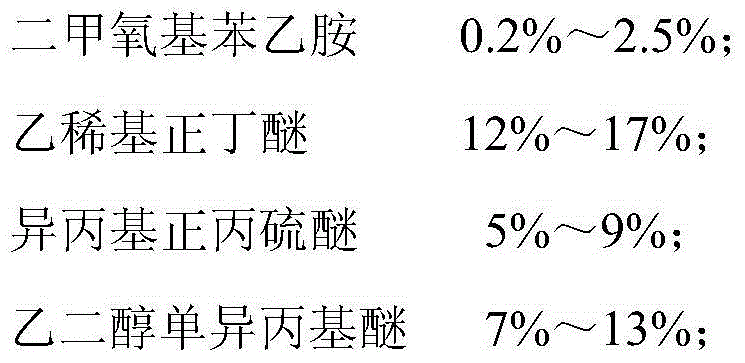

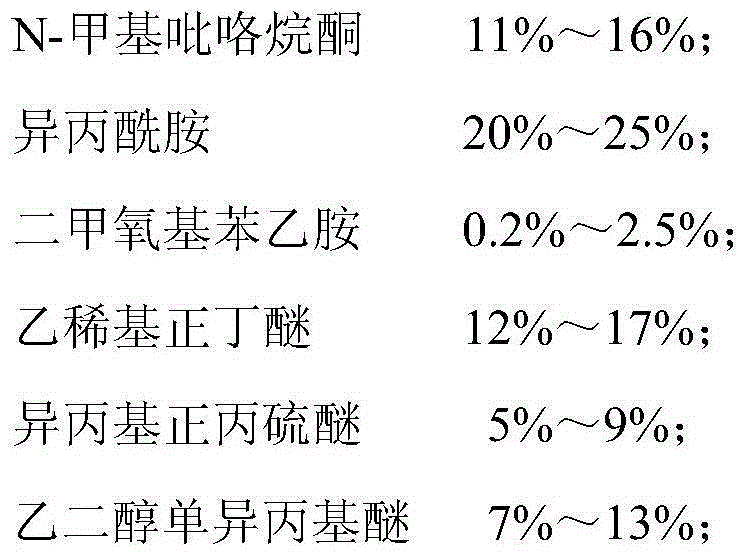

The invention discloses aluminum film water system photoresistance stripping liquid in a liquid crystal panel manufacture technology and a preparation method thereof. The aluminum film water system photoresistance stripping liquid comprises the following compositions in percentage by weight: 11-16% of N-methylpyrrolidone, 20-25% ofisopropylamide, 0.2-2.5% of dimethoxy phenethylamine, 12-17% of N-butyl vinyl ether, 5-9% of isopropyl dipropyl sulfide, 7-13% of ethylene glycol monoisopropyl ether and the balance of water. The aluminum film water system photoresistance stripping liquid and the preparation method of the aluminum film water system photoresistance stripping liquid can improve the photoresistance stripping performance of a liquid crystal panel product, lowers technological condition temperature and avoids damage on human bodies and the environment by positive photoresist stripping liquid which is originally used.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Lubrication emulsified oil for stainless steel tube drawing and production method thereof

InactiveCN102533419AImprove adsorption capacityReduce wearLubricant compositionN-butyl vinyl etherButylated hydroxytoluene

The invention discloses lubrication emulsified oil for stainless steel tube drawing, which comprises the following raw materials in weight percentage: 5-15 percent of chlorinated paraffin, 1-5 percent of 2,6-butylated hydroxytoluene, 1-5 percent of zinc dialkyl dithiophosphate, 1-10 percent of poly-vinyl butyl ether, 1-12 percent of oleic acid, 1-12 percent of triethanolamine, 1-8 percent of lead naphthenate, 1-6 percent of dibutyl phthalate, 1-26 percent of LN46 machine oil and the balance transformer oil. A production method for the lubrication emulsified oil for the stainless steel tube drawing comprises the following steps of: adding the machine oil and the transformer oil into a reaction kettle in sequence; heating to 40-50 DEG C; starting a stirrer; and then, slowly adding the chlorinated paraffin, the oleic acid, the triethanolamine, the lead naphthenate, the dibutyl phthalate, the 2,6-butylated hydroxytoluene, the zinc dialkyl dithiophosphate and the poly-vinyl butyl ether into the reaction kettle in sequence, wherein each time a kind of material is added, the raw materials are independently stirred for 10-30 min; continuously stirring for 2h after all the raw materials are added; and blowing and packaging.

Owner:DALIAN SANDAAOKE CHEM

Bronze powder pigment for printing ink and preparation method of bronze powder pigment

InactiveCN104277577AImprove hydrophobicityGood dispersionInksPigment treatment with macromolecular organic compoundsN-butyl vinyl etherPrinting ink

The invention discloses a bronze powder pigment for printing ink. The bronze powder pigment is characterized by consisting of the following raw materials in parts by weight: 40-50 parts of micron-level sheet-shaped bronze powder, 0.05-0.1 part of zinc naphthenate, 1-2 parts of talcum powder, 6-8 parts of tetraethoxysilane, 0.3-0.5 part of a silane coupling agent KH-550, 0.05-0.1 part of N-sodium methyl taurate, 1-2 parts of wool fat, 0.1-0.2 part of poly(n-butyl vinyl ether), 0.5-1 part of sebacic acid, 4-8 parts of ethyl acetate, 0.01-0.03 part of ceteareth-25, 0.1-0.2 part of a silane coupling agent A-151 and 1-2 parts of a compound additive. The bronze powder pigment disclosed by the invention has good dispersion in organic resin, high glossiness and good stability, and is suitable for the printing ink application field.

Owner:HEFEI SUNRISE PIGMENTS

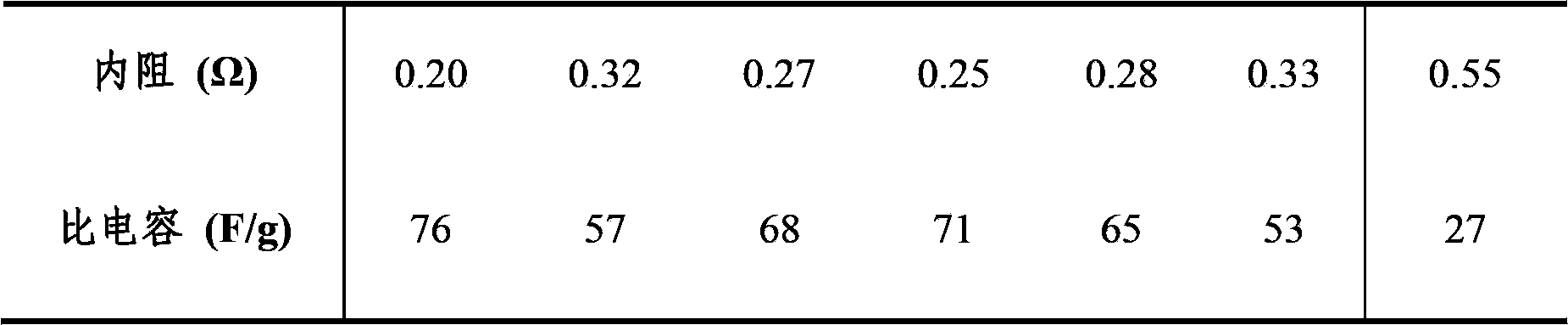

Preparation method of polyethylene n-butyl ether based gel polymer electrolyte capacitor

InactiveCN103456500AGood compatibilityIncrease contactCapacitor electrolytes/absorbentsPolymer electrolytesPolymer science

The invention relates to the technical field of capacitors, and provides a preparation method of a polyethylene n-butyl ether based gel polymer electrolyte capacitor. The method is characterized by including the steps: according to a sequence of electrode / membrane / electrode, sequentially overlaying and coiling, and mounting a coiled product in a capacitor shell; mixing a quaternary ammonium salt ion liquid electrolyte of 0.5-2mol / L , N-butyl vinyl ether and an initiator according to a mass ratio of (5-10):1:(0.002-0.02) to obtain a mixed solution; injecting the mixed solution into the capacitor shell prior to sealing, and placing the capacitor shell injected with the mixed solution at the temperature of 60-80 DEG C for 12-48 hours to obtain the polyethylene n-butyl ether based gel polymer electrolyte capacitor. The method is simple and feasible, and beneficial to large-scale industrial application.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

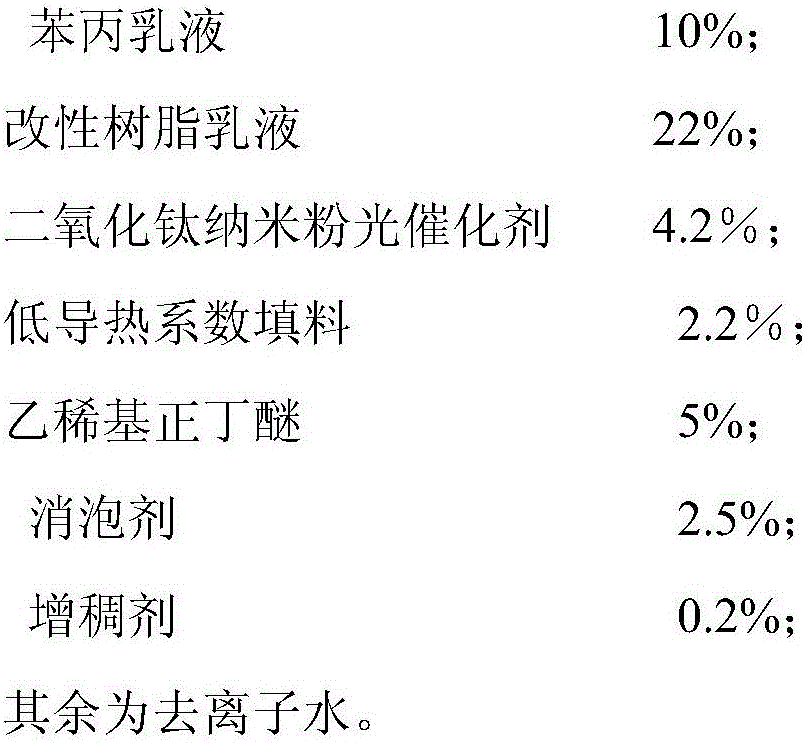

Preparation method of aluminum film water-based light-resistant stripping liquid in thin film liquid crystal display

InactiveCN105573070AImproved photoresist stripping performanceAvoid damagePhotosensitive material processingWater basedN-butyl vinyl ether

The invention discloses a preparation method of aluminum film water-based light-resistant stripping liquid in a manufacturing process of liquid crystal panels. According to the preparation method, the stripping liquid comprises the following compositions in percentage by weight: 10%-16% of a potassium hydroxide solution, 12%-20% of a triethanolamine solution, 1.2%-2.8% of o-fluorobenzoic acid, 5%-15% of n-butyl vinyl ether, 2.5%-6.9% of isopropyl dipropyl sulfide, 0.2%-0.6% of pure sulfuric acid and the balance of deionized water. According to the aluminum film water-based light-resistant stripping liquid, the water-based light-resistant stripping performance of liquid crystal panel products can be improved, the temperature of process conditions is decreased, and the damages caused by originally utilized positive photoresist stripping liquid to the human body and the environment are avoided.

Owner:WUXI JIJIN ENVIRONMENTAL PROTECTION TECH CO LTD

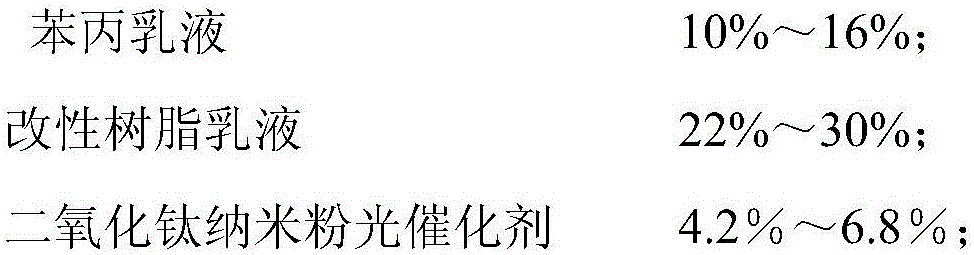

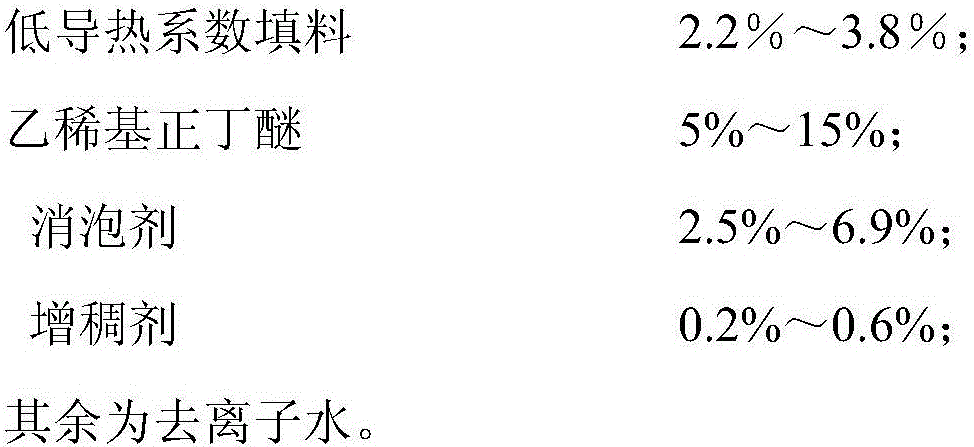

Environment-friendly building coating and preparation method thereof

InactiveCN106147526AReduce cooling energy consumptionImprove heat insulationEpoxy resin coatingsEmulsionN-butyl vinyl ether

The invention discloses an environment-friendly building coating and a preparation method thereof. The coating comprises, by weight percentage, 10-16% of styrene-acrylic emulsion, 22-30% of modified resin emulsion, 4.2-6.8% of titanium dioxide nano-powder photocatalyst, 2.2-3.8% of rigid polyurethane foam powder, 5-15% of N-butyl vinyl ether, 2.5-6.9% of antifoaming agent, 0.2-0.6% of thickening agent, and the balance deionized water. The titanium dioxide nano-powder photocatalyst is added based on an existing indoor building coating to improve performances of the building coating in decomposing harmful microorganisms and harmful gas; N-butyl vinyl ether is added so that the catalytic effect of the titanium dioxide nano-powder photocatalyst can be greatly improved, and the harmful microorganism decomposition capability of the coating is enhanced.

Owner:佛山杰致信息科技有限公司

High-flash-point transformer oil and preparation method thereof

InactiveCN106635329AImprove performanceHigh ignition pointLubricant compositionN-butyl vinyl etherButylated hydroxytoluene

The invention discloses high-flash-point transformer oil, prepared from the following raw materials: silicone oil transformer oil, large molecule hydrocarbon transformer oil, synthetic ester transformer oil, rapeseed oil, modified nano-titanium dioxide, butylated hydroxytoluene, benzotriazole, n-dodecyl benzene, dibutyl phthalate, polyimide, poly-n-butyl vinyl ether, polyethylene sulphonate, ethylene diamine, an ultraviolet absorbent, a silane coupling agent KH-560, a metallic passivator T551 and an auxiliary agent. The invention also provides a preparation method of the high-flash-point transformer oil. The prepared transformer oil is high in flash point and good in comprehensive performance.

Owner:马光德

Transformer oil with lubricating effect

InactiveCN105296094AImprove stabilityImprove thermal conductivityLubricant compositionN-butyl vinyl etherPolystyrene

The invention discloses transformer oil with a lubricating effect. The transformer oil with the lubricating effect is prepared from, by weight, 4-5 parts of zinc acetylacetonate, 0.7-1 part of oleic acid, 20-24 parts of ethyl alcohol, 2-3 parts of polyimide, 0.2-0.4 part of ethidene diamine, 0.4-0.6 part of silane coupling agent KH570, 1000-1100 parts of transformer base oil, 2-3 parts of polystyrolsulfon acid, 0.3-0.4 part of stearic acid, 20-25 parts of sufurized oil, 3-4 parts of polyurethane emulsion, 2.4-2.6 parts of carclazyte, 3.4-3.8 parts of graphite, 3.1-3.4 parts of molybdenum sulfide, 0.3-0.4 part of antioxidant 1010 and 0.6-0.8 part of polyvinyl butyl ether. The transformer oil with the lubricating effect is simple in preparation method, low in production cost, capable of lubricating and insulating, high in heat conduction, good in oxidation stability, suitable for large-scale production and worthy of promotion.

Owner:TONGLING SANJIA TRANSFORMER

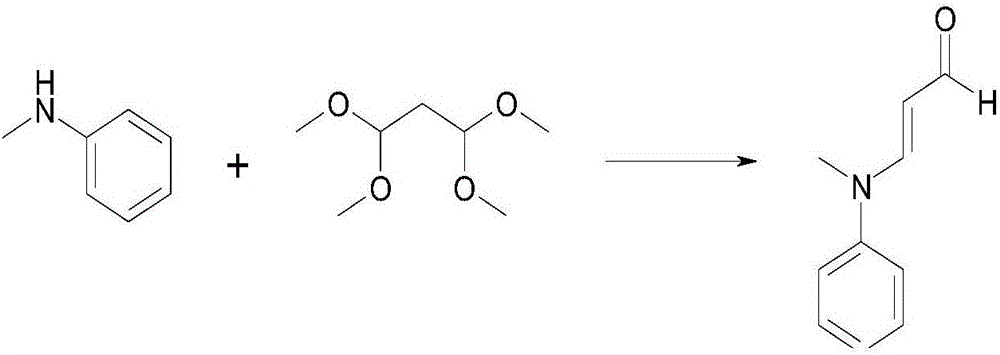

Preparation method of 3-(N-methyl-N-phenyl)aminoacrolein

InactiveCN106431942ALow costThree wastes less pollutionOrganic chemistryOrganic compound preparationN-butyl vinyl etherOrganic layer

The invention relates to the technical field of pharmaceutical intermediates, in particular to a preparation method of 3-(N-methyl-N-phenyl)aminoacrolein. The preparation method comprises the following steps that tetramethoxypropane and N-methylaniline are put into a reaction flask, and after stirring is conducted for 10 min, diluted hydrochloric acid is dropwise added; after diluted hydrochloric acid is dropwise added completely, stirring is conducted for 2.5 h at the temperature of 24 DEG C to 26 DEG C; methylbenzene is added, and caustic soda liquid is dropwise added at 30 DEG C or below to regulate the pH value to be 6-7; standing is conducted for layering, a water layer is extracted with methylbenzene, organic layers are mixed, and washing is conducted three times with a saturated salt solution; standing is conducted for layering, a solvent in the organic layer is recycled by reducing pressure, 60-70-DEG C 40-mmHg distillates are collected, and then the product is obtained. According to the preparation method, expensive N-methylformanilide, n-butyl vinyl ether and propargyl alcohol are not used as raw materials, and therefore the cost is reduced; due to the fact that conventional solvents such as acetonitrile and chlorobenzene and poisonous substances such as triphosgene are not used, three waste pollution is reduced, and the reaction yield is increased; in the synthesis process, reacting is conducted at the environment temperature, the operation process is simplified, impurity generation is reduced, the quality of the product is improved, and the reaction yield is increased.

Owner:JINTAN DEPEI CHEM

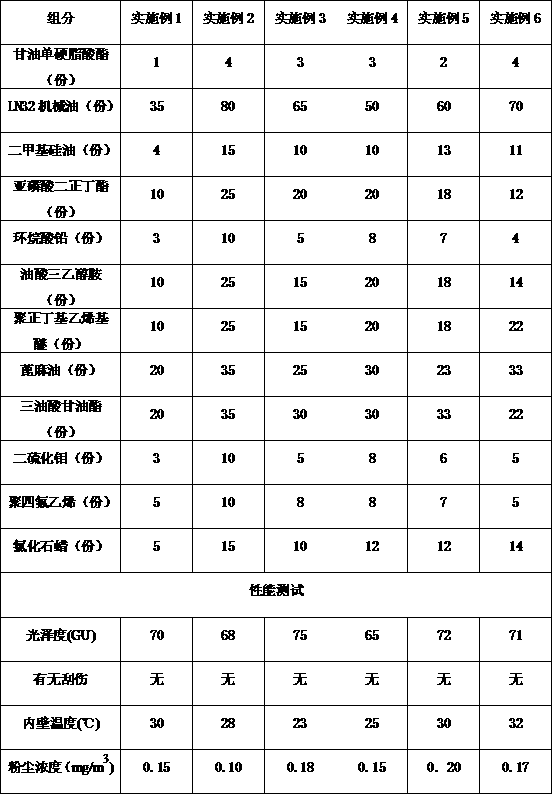

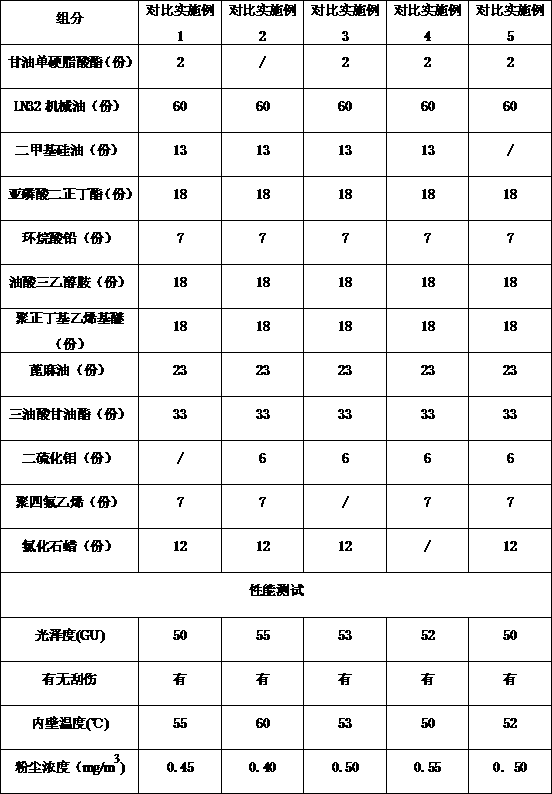

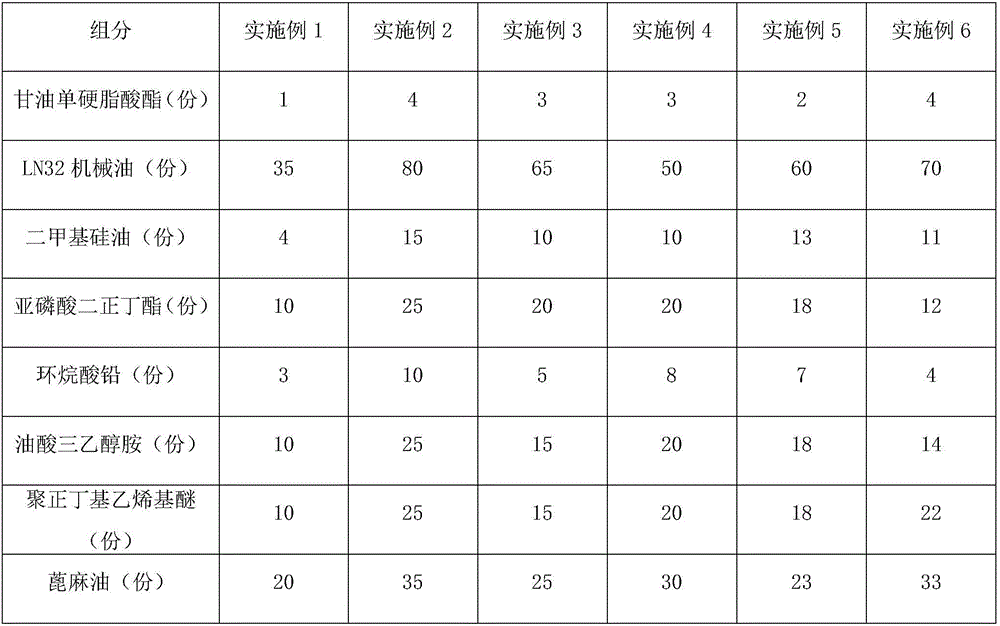

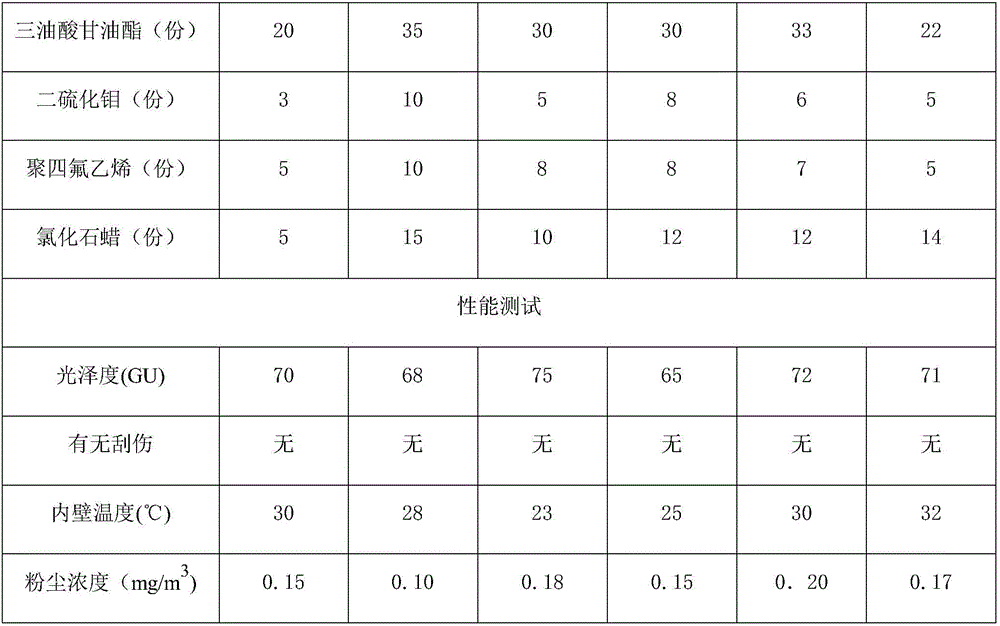

Lubricant for titanium-magnesium alloy drawing process and preparation method thereof

InactiveCN109423352AImprove the lubrication effectEnhance aggregation abilityLubricant compositionN-butyl vinyl etherChlorinated paraffins

The invention discloses a lubricant for a titanium-magnesium alloy drawing process. The lubricant is prepared from the following components in parts by weight: 1-4 parts of glycerol monostearate, 35-80 parts of LN32 mechanical oil, 3-10 parts of chlorinated paraffin, 4-15 parts of dimethyl silicone oil, 10-25 parts of di-n-butyl phosphite, 3-10 parts of lead naphthenate, 10-25 parts of triethanolamine oleate, 10-25 parts of poly-n-butyl vinyl ether, 20-35 parts of castor oil, 20-35 parts of glyceryl trioleate, 3-10 parts of a solid sulfur-based lubricating additive, 5-10 parts of a polymer lubricating additive and 5-15 parts of a stabilizing assistant. The lubricant disclosed by the invention can prevent the surface of a stamped workpiece from being scratched, rusted, the surface smoothness can be guaranteed, the demolding is easy, the dust hazard in a workshop is avoided, the production efficiency is improved, the preparation method disclosed by the invention is simple and feasible; the cost is low; the process controllability is high; and the preparation method is suitable for the production market demand of drawing lubricants.

Owner:刘亮基

A kind of high-viscosity low-temperature hydraulic oil and preparation process thereof

ActiveCN104789310BGood viscosity and temperatureImprove wear resistanceLubricant compositionEnvironmental resistanceN-butyl vinyl ether

The invention discloses a high-viscosity low-temperature hydraulic oil, which includes components A, B and C, component A includes components A and B, and its components include the following components in parts by mass: component A: polyα- 42-48 parts of olefins, 36-42 parts of heavy alkyl benzene, 15-25 parts of LVI300 base oil; component B: 12-20 parts of poly-n-butyl vinyl ether, 6-12 parts of polymethacrylate; Component C: Component A: 1‑2 parts of sodium dodecylbenzenesulfonate, 3‑5 parts of potassium dihydrogen phosphate, 2‑4 parts of sulfurized calcium alkylphenate; Component B: 6‑9 parts of polyacrylamide 8-10 parts of phosphoric acid, 7-13 parts of polysorbate; the invention also discloses a preparation process of high-viscosity low-temperature hydraulic oil; the product of the invention has high viscosity and good tension, and the manufacturing process is safe, stable and environmentally friendly.

Owner:SUZHOU TONGMING MACHINERY

High-speed drawing lubricating cooling oil of nickel-chromium stainless steel and production method

InactiveCN101029270BImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherChlorinated paraffins

Owner:DALIAN SANDAAOKE CHEM

High-viscosity low-temperature hydraulic oil and preparation process thereof

ActiveCN104789310AGood viscosity and temperatureImprove wear resistanceLubricant compositionPolyolefinN-butyl vinyl ether

The invention discloses a high-viscosity low-temperature hydraulic oil. The high-viscosity low-temperature hydraulic oil comprises a component I, a component II and a component III, wherein the component I comprises a component A and a component B. The high-viscosity low-temperature hydraulic oil comprises the following components in parts by weight: the component I: 42-48 parts of poly-alpha-olefin, 36-42 parts of heavy alkyl benzene, and 15-25 parts of base oil No. LVI300; the component II: 12-20 parts of poly(n-butyl vinyl ether) and 6-12 parts of polymethacrylate; the component III: the component A including 1-2 parts of sodium dodecyl benzene sulfonate, 3-5 parts of monopotassium phosphate, and 2-4 parts of sulfurized calcium alkyl phenolate; the component B including 6-9 parts of polyacrylamide, 8-10 parts of phosphoric acid and 7-13 parts of polysorbate. The invention further discloses a preparation process of the high-viscosity low-temperature hydraulic oil. According to the high-viscosity low-temperature hydraulic oil and the preparation process of the high-viscosity low-temperature hydraulic oil, the product viscosity is high, the tension is large, and the manufacturing procedure is safe, stable and environment-friendly.

Owner:SUZHOU TONGMING MACHINERY

Lubrication emulsified oil for stainless steel tube drawing and production method thereof

InactiveCN102533419BImprove adsorption capacityReduce wearLubricant compositionN-butyl vinyl etherButylated hydroxytoluene

The invention discloses lubrication emulsified oil for stainless steel tube drawing, which comprises the following raw materials in weight percentage: 5-15 percent of chlorinated paraffin, 1-5 percent of 2,6-butylated hydroxytoluene, 1-5 percent of zinc dialkyl dithiophosphate, 1-10 percent of poly-vinyl butyl ether, 1-12 percent of oleic acid, 1-12 percent of triethanolamine, 1-8 percent of lead naphthenate, 1-6 percent of butyl phthalate, 1-26 percent of LN46 machine oil and the balance transformer oil. A production method for the lubrication emulsified oil for the stainless steel tube drawing comprises the following steps of: adding the machine oil and the transformer oil into a reaction kettle in sequence; heating to 40-50 DEG C; starting a stirrer; and then, slowly adding the chlorinated paraffin, the oleic acid, the triethanolamine, the lead naphthenate, the butyl phthalate, the 2,6-butylated hydroxytoluene, the zinc dialkyl dithiophosphate and the poly-vinyl butyl ether into the reaction kettle in sequence, wherein each time a kind of material is added, the raw materials are independently stirred for 10-30 min; continuously stirring for 2h after all the raw materials are added; and blowing and packaging.

Owner:DALIAN SANDAAOKE CHEM

Zinc-coated steel-plated punch drawing lube oil and its production

InactiveCN101029271BImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherParaffin oils

A galvanized steel plate punch stretch lube oil consists of motor oil 45-55wt%, castor oil 2-4wt%, soya oil 25-35wt%, mersolates 0.5-1.5wt%, zinc naphthenate 0.5-1.5wt%, triethyl phosphate 2-4wt%, chlorinated paraffin 3-5wt%, butyl-octanol zinc salt phosphinothioyl 2-4wt%, poly-n-butyl vinyl ether 4-6wt% and bactericide 0.2-0.3wt%. The process is carried out by adding motor oil into reactor, heating to 90-100degree, agitating at 750-850 / min, adding into mersolates, zinc naphthenate, chlorinated paraffin and triethyl phosphate successively, agitating for 1.5-2.5hrs, lowering temperature to 50-60degree, adding into castor oil, soya oil and bactericide, agitating for 0.5-1.5hrs, lowering to normal temperature, adding into butyl-octanol zinc salt phosphinothioyl and poly-n-butyl vinyl ether, and agitating at 75-85 / min and agitating 1.5-2.5hrs. It has better oil-film continuity and adsorption and prevents punch work-piece from being scraped and corrosion.

Owner:DALIAN SANDAAOKE CHEM

Drawing lube cooling oil of aluminum-coated red copper metal bar and its production

InactiveCN101029266BImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherOleic Acid Triglyceride

Owner:DALIAN SANDAAOKE CHEM

Environment-friendly lubricating oil and preparation method thereof

InactiveCN107523392AImprove wear resistanceIncreased extreme pressure performanceLubricant compositionN-butyl vinyl etherPotassium

The invention discloses a preparation method of environment-friendly lubricating oil. The preparation method includes the steps: roasting a ZSM-5 molecular sieve for 2-3h at the temperature of 300-400 DEG C; adding potassium chloride, ammonium chloroplatinate and water, heating mixture, and performing reflux reaction on the mixture for 3-4h; heating the mixture to reach the temperature of 120-130 DEG C, and soaking the mixture for 6-8h; filtering and drying the mixture, and performing reduction on the mixture for 2-3h at the temperature of 400-600 DEG C in the atmosphere of H2 / N2 to obtain a material A; adding and rapidly stirring nano-aluminum oxide, nano-zirconium silicate and poly-n-butyl vinyl ether at the normal temperature, and performing reaction on mixture for 30-50min to obtain a material B; mixing allylboronic acid pinacol ester, N-hydroxymethylphthalimide, methyl silicone oil, dodecyl diphenylamine and base oil, stirring mixture at the temperature of 80-120 DEG C, and performing reaction on the mixture for 40-60min; adding the material A and the material B, heating mixture to reach the temperature of 130-150 DEG C, stirring the mixture, performing reaction on the mixture for 1-3h, soaking the mixture, keeping the temperature of the mixture, and performing reaction on the mixture for 40-50min; cooling the mixture to obtain the environment-friendly lubricating oil.

Owner:WUJIANG HUAWEI SPECIAL OIL

Lubricating oil for stamping and drawing of stainless steel plate

InactiveCN103756763BImprove the lubrication effectImprove cooling effectLubricant compositionPhosphorous acidTert butyl phenol

The invention discloses a stainless steel stamping tension lubricating oil which comprises the following components in parts by mass: 1-2 parts of glycerin monostearate, 55 parts of LN32 mechanical oil, 8 parts of chlorinated paraffin, 4 parts of dimethyl silicon oil, 19 parts of phosphorous acid di-n-butyl phosphate, 8 parts of lead naphthenate, 23 parts of triethanolamine oleate, 9 parts of poly(n-butyl) vinyl ether, 35 parts of transformer oil, 17 parts of vulcanized whale oil, 2 parts of 2.6-di-tert-butyl phenol and 1 part of hydroxypropyl methyl cellulose. The stainless steel stamping tension lubricating oil is good in lubrication and cooling property and easy to demold, and is capable of preventing a stamped surface from scratch or rusting, ensuring surface smoothness and cleanness, and meeting the direct assembling requirements.

Owner:CHANGSHU MEIERTE METAL PROD

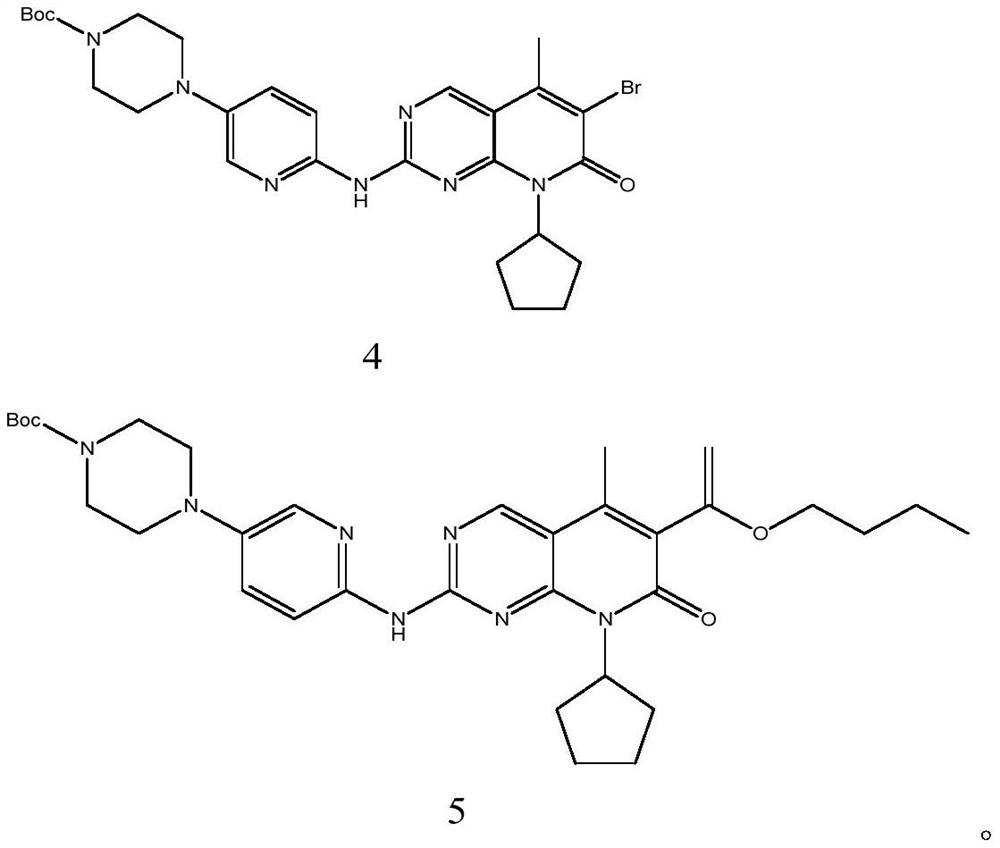

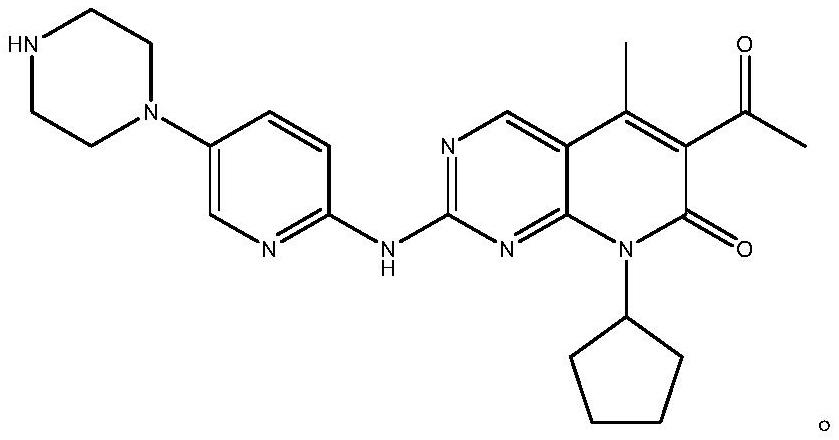

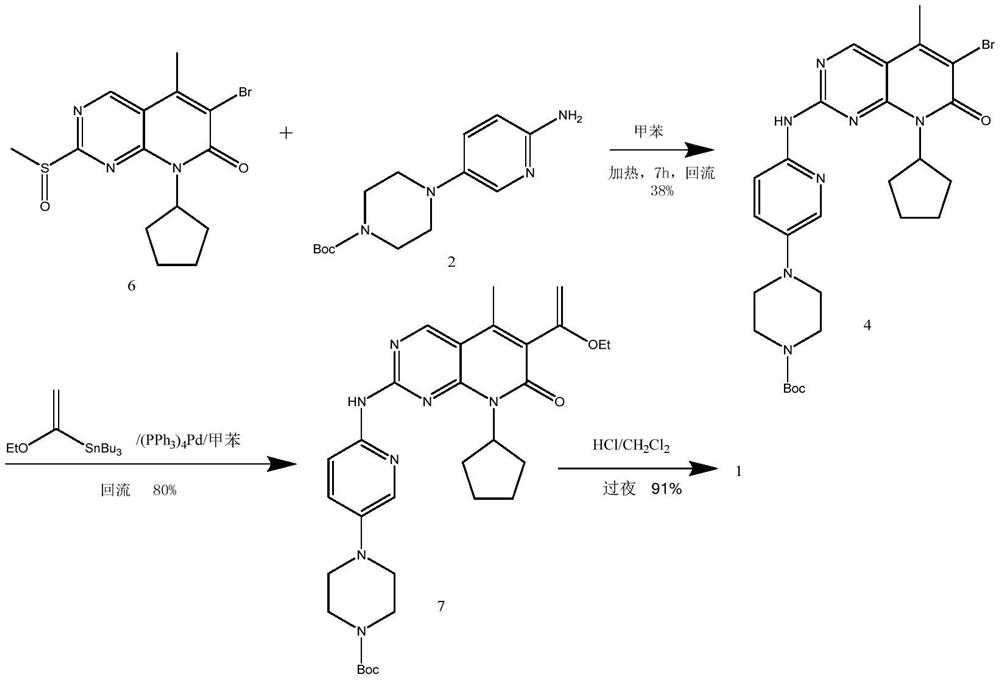

Low-cost preparation method of palbociclib

ActiveCN113683612AImprove filtering effectMild reaction conditionsOrganic chemistryBulk chemical productionN-butyl vinyl etherPtru catalyst

The invention discloses a low-cost preparation method of palbociclib. The method comprises the steps: taking 4-(6-aminopyridin-3-yl)piperazine-1-carboxylic acid tert-butyl ester as an initial raw material, taking large-steric-hindrance alkali as an acid-binding agent, carrying out nucleophilic substitution reaction with a compound represented by a formula 3, carrying out post-treatment, quenching and dealkalizing to obtain a large-particle compound represented by a formula 4; then taking n-butyl alcohol and water as solvents, taking diisopropylethylamine as an acid-binding agent and a protective agent, and under the action of a composite catalyst palladium chloride and cuprous iodide, carrying out a Herk alkylation reaction with n-butyl vinyl ether; and under the protection of an organic alkali, refining with an ester solvent to obtain a high-purity compound represented by a formula 5 with high yield, and hydrolyzing the compound represented by the formula 5 through a mixed solvent of n-butyl alcohol, anisole and water under an acidic condition to obtain a finished product of palbociclib. The method greatly reduces the usage amount of a palladium catalyst, and is simple and convenient to operate, less in environmental pollution, high in yield, high in product quality and more suitable for industrial production.

Owner:SHANDONG BOYUAN PHARM CO LTD

Lubricating agent used for titanium magnesium alloy drawing process and preparation method thereof

InactiveCN106701285AImprove the lubrication effectEnhance aggregation abilityLubricant compositionN-butyl vinyl etherChlorinated paraffins

The invention discloses a lubricating agent used for a titanium magnesium alloy drawing process. The lubricating agent comprises the following components in parts by weight: 1-4 parts of glyceryl monostearate, 35-80 parts of LN32 machine oil, 3-10 parts of chlorinated paraffin, 4-15 parts of dimethyl silicon oil, 10-25 parts of di-n-butyl phosphite, 3-10 parts of lead naphthenate, 10-25 parts of triethanolamine oleate, 10-25 parts of poly n-butyl vinyl ether, 20-35 parts of castor oil, 20-35 parts of triglyceride, 3-10 parts of a solid sulfenyl lubricating additive, 5-10 parts of a macromolecular polymer lubricating additive and 5-15 parts of a stable additive. The lubricating agent disclosed by the invention can prevent scratch and corrosion from appearing on the surface of a stamping workpiece, surface smoothness can be guaranteed, demoulding is easy, dust hazards in a workshop are completely eradicated, and the production efficiency is improved; and a preparation method of the lubricating agent is simple and feasible, the cost is low, the process controllability is strong, and the lubricating agent is applicable to production market demands of a drawing lubricating agent.

Owner:FOSHAN KEITH TITANIUM TECH CO LTD

Cold-rolling steel-plate punch drawing lube oil and its production

InactiveCN101029272BImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherParaffin oils

A cold-rolling steel-plate punch stretch lube oil consists of motor oil 45-55wt%, castor oil 6-10wt%, soya oil 8-12wt%, barium mahogany acid 1-3wt%, lead naphthenate 1-3wt%, chlorinated paraffin 10-20wt%, butyl-octanol zinc salt phosphinothioyl 4-6wt% and poly-n-butyl vinyl ether 6-10wt% and bactericide 0.2-0.3wt%. The process is carried out by adding motor oil into reactor, heating to 90-100degree, adding into barium mahogany acid, lead naphthenate and chlorinated paraffin, agitating at 750-850 / min for 1.5-2.5hrs, lowering temperature to 50-60degree, adding into castor oil, soya oil and bactericide, agitating for 0.5-1.5hrs, lowering to normal temperature, adding into butyl-octanol zinc salt phosphinothioyl and poly-n-butyl vinyl ether and agitating at 85-95 / min for 1.5-2.5hrs. It has better oil-film continuity and adsorption and prevents punch work-piece from being scraped and corrosion.

Owner:DALIAN SANDAAOKE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com