Environment-friendly building coating and preparation method thereof

An architectural coating and environmental protection technology, which is applied in the field of environmental protection architectural coatings and its preparation, can solve the problems of non-decomposition and high content of volatile organic compounds, and achieve enhanced decomposition ability, improved catalytic effect, and improved heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

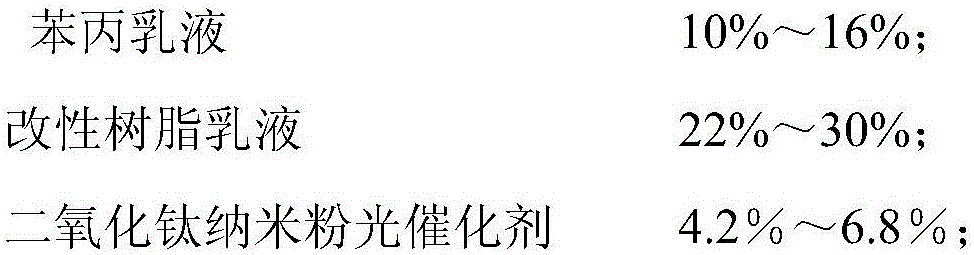

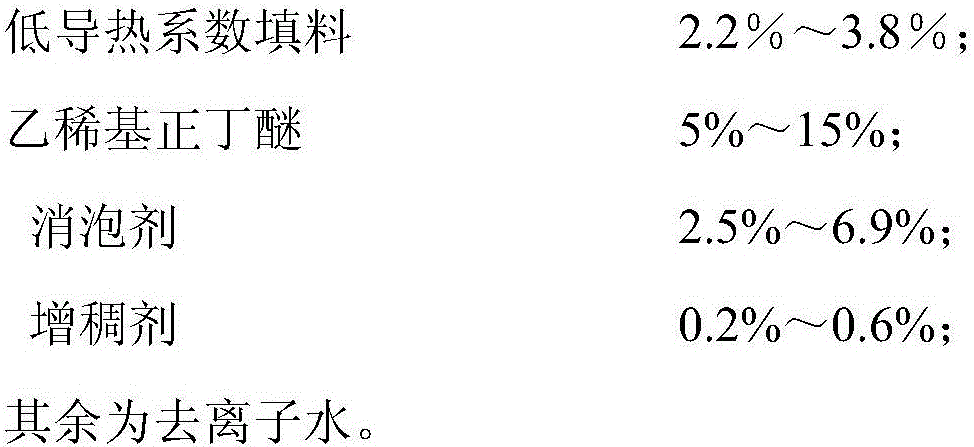

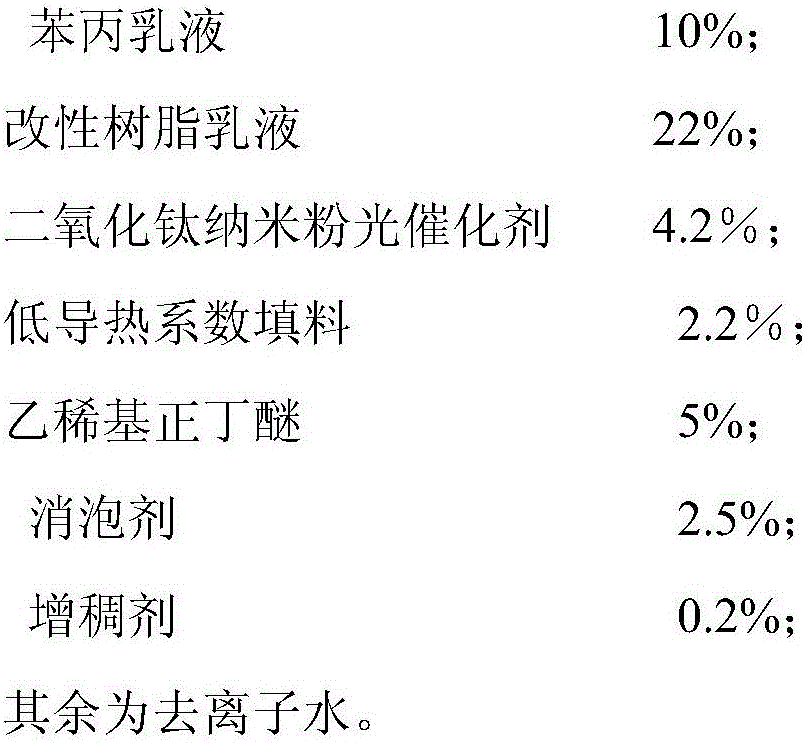

[0025] Embodiment 1, the first step, weigh 10kg of styrene-acrylic emulsion, then slowly add it into the reaction kettle filled with 53.9kg of deionized water through the automatic feeding system, and fully stir, the stirring temperature is 40 degrees, and the stirring pressure is 1.2Mpa, the stirring time is 10 minutes, and the stirring speed is 45 rpm;

[0026] In the second step, weigh 22kg of modified resin emulsion and 2.2kg of diatomite and clay-made low thermal conductivity fillers, and slowly add them to the reaction kettle through the automatic feeding system in turn, and stir fully. The temperature is 30 degrees, the stirring air pressure is 2.2Mpa, the stirring time is 15 minutes, and the stirring speed is 55 rpm;

[0027] The third step is to weigh 4.2kg of titanium dioxide nano-powder photocatalyst and 5kg of vinyl n-butyl ether, and slowly add them to the reaction kettle through the automatic feeding system in turn, and stir fully. The stirring temperature is 40 ...

Embodiment 2

[0034] Embodiment 2, the first step, weigh 13kg of styrene-acrylic emulsion, then slowly add it into the reaction kettle filled with 33.7kg of ionized water through the automatic feeding system, and fully stir, the stirring temperature is 45 degrees, and the stirring air pressure is 1.5Mpa, the stirring time is 12 minutes, and the stirring speed is 48 rpm;

[0035] In the second step, weigh 26kg of modified resin emulsion and 3.2kg of low thermal conductivity filler made of clay and precipitated barium sulfate, and slowly add them to the reaction kettle through the automatic feeding system in turn, and stir fully. The temperature is 35 degrees, the stirring air pressure is 2.5Mpa, the stirring time is 18 minutes, and the stirring speed is 58 rpm;

[0036] The third step is to weigh 5.5 kg of titanium dioxide nano-powder photocatalyst and 10 kg of vinyl n-butyl ether, and slowly add them to the reaction kettle through the automatic feeding system in turn, and stir fully. The st...

Embodiment 3

[0043] Embodiment 3, the first step, weigh 16kg of styrene-acrylic emulsion, then slowly add it into the reaction kettle filled with 20.9kg of deionized water through the automatic feeding system, and fully stir, the stirring temperature is 50 degrees, and the stirring pressure is 1.8Mpa, the stirring time is 15 minutes, and the stirring speed is 50 rpm;

[0044]In the second step, weigh 30kg of modified resin emulsion and 3.8kg of low thermal conductivity filler made of precipitated barium sulfate and calcium silicate powder, and slowly add them to the reaction kettle through the automatic feeding system in turn, and fully stir , the stirring temperature is 38 degrees, the stirring air pressure is 2.8Mpa, the stirring time is 20 minutes, and the stirring speed is 60 rpm;

[0045] The third step is to weigh 6.8kg of titanium dioxide nano-powder photocatalyst and 15kg of vinyl n-butyl ether, and slowly add them to the reaction kettle through the automatic feeding system in turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com