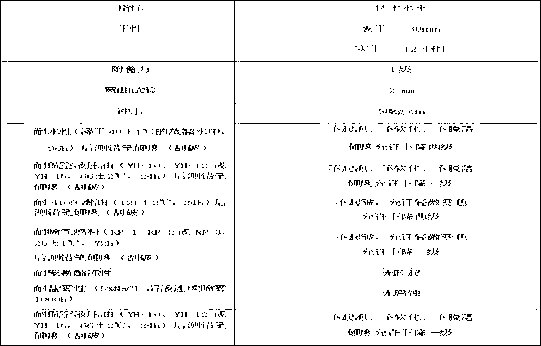

Patents

Literature

550 results about "Dimethylbenzenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

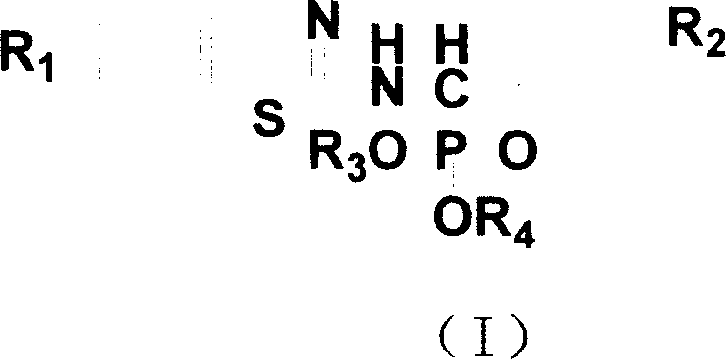

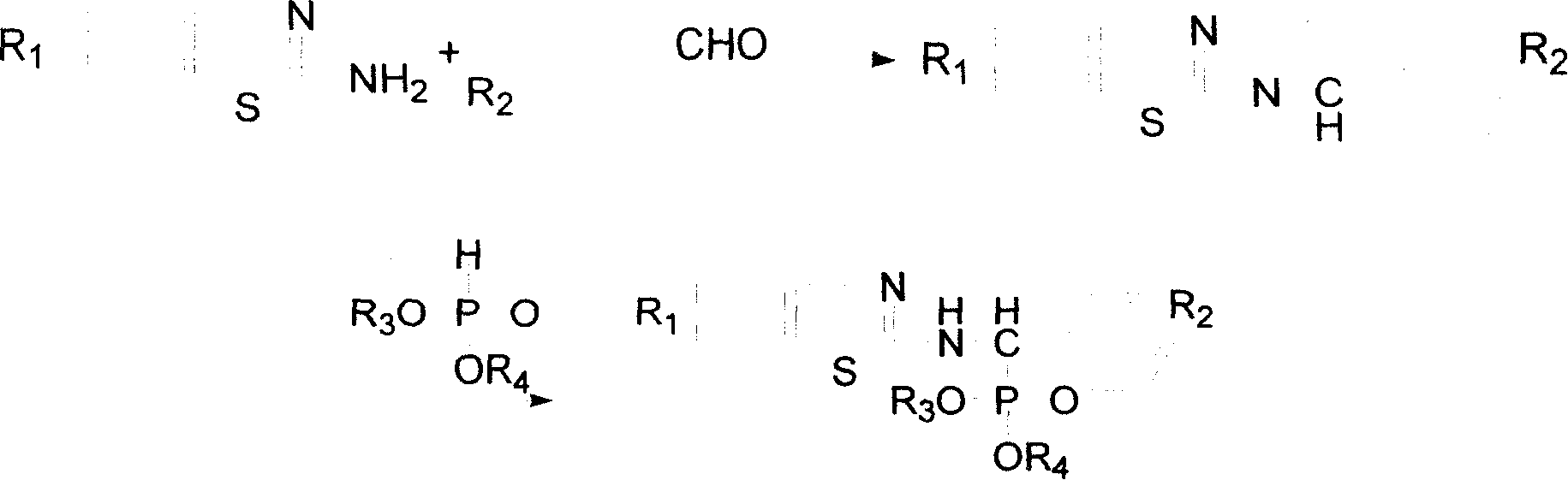

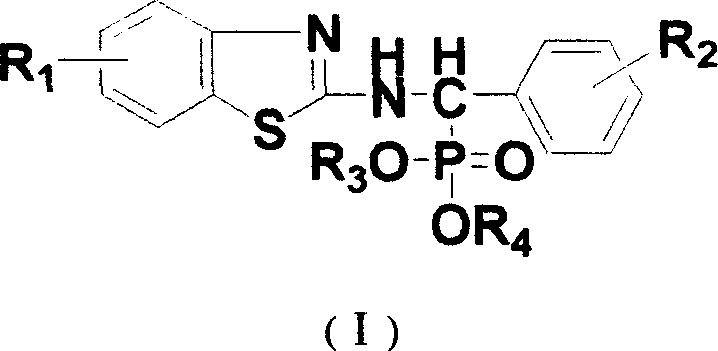

N-substituted benzothiazolyl-1-substituted phenyl-0, 0-dialkyl-alpha-amino phosphonate ester derivatives preparation and application

The present invention discloses a medicine with actions of resisting plant virus and resisting tumor-N-substituted benzothiazolyl-1-substituted phenyl-0.0-dialkyl-alpha- aminophosphonates derivative, its preparation method and biological activity. Said invention also provides its structure formula, and also provides its extensive application for inhibiting tobacco mosaic virus (TMV) activity and inhibiting activity of human body prostatic cancer cell PC3 and others.

Owner:GAUNGXI TIANYUAN BIOCHEM

Catalyst for producing dimethylbenzene by alkylation of benzene and methanol

InactiveCN102600887AHigh xylene selectivityHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystBenzeneMolecular sieve

The invention relates to a catalyst for producing dimethylbenzene by alkylation of benzene and methanol. The catalyst mainly overcomes the shortcomings of low utilization rate of methanol alkylation, low conversion rate of benzene and low selectivity of dimethylbenzene in the actual application of the catalyst reported in previous literatures. Through the adoption of the technical scheme of loading alkaline earth and rare-earth metal elements on a hydrogen-type MCM-22 molecular sieve, the problem is well solved. The catalyst provided by the invention is high in selectivity and can be used in the production process of dimethylbenzene by alkylation of benzene and methanol.

Owner:TONGJI UNIV

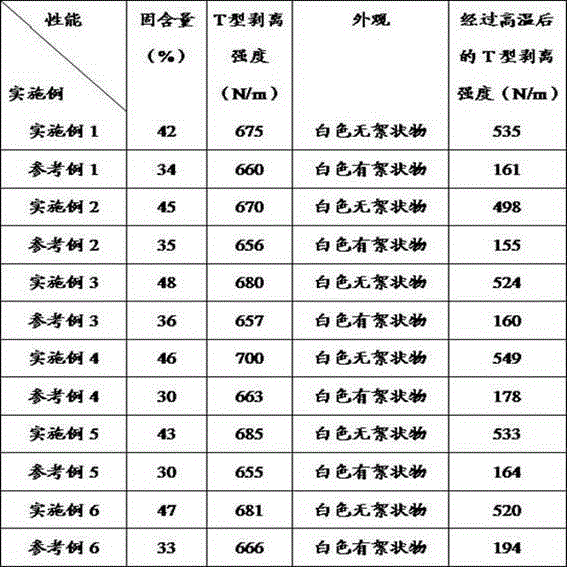

High-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and preparation method thereof

The invention discloses a high-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and a preparation method thereof. The preparation method comprises the following steps of: synthesizing modified phenolic resin, preparing polyurethane prepolymer, synthesizing modified polyurethane prepolymer, and synthesizing the modified polyurethane adhesive, wherein the step of synthesizing the modified phenolic resin is carried out by adding methoxyl dimethylbenzene monomer and phenols in phenolic resin to react under the effect of an acid catalyst, cooling the mixture, and then adding a basic catalyst, solvent and formaldehyde in the mixture for dehydration reaction under vacuum until the mixture is transparent, thus obtaining the modified phenolic resin; the step of preparing the polyurethane prepolymer is carried out by adding polyisocyanates and polyester polyol in the modified phenolic resin for reacting; the step of synthesizing the modified polyurethane prepolymer is carried out by modifying the polyurethane prepolymer through the modified phenolic resin to obtain the modified polyurethane prepolymer; and the step of synthesizing the modified polyurethane adhesive is carried out by adding water to the modified polyurethane prepolymer, and dispersing the modified polyurethane prepolymer through dispersing agent, and finally adding neutralizing agent, cross-linking agent and chain extender into the dispersed modified polyurethane prepolymer to obtain the modified aqueous polyurethane adhesive. The preparation method disclosed by the invention is simple, and improves the bonding strength and high temperature resistance of the polyurethane adhesive.

Owner:高金技术产业集团有限公司

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Alkyd resin for wood lacquer and preparation method thereof

The invention discloses alkyd resin for wood lacquer and a preparation method thereof. According to the raw material formula, the alkyd resin for the wood lacquer comprises the following components in percentage by mass: 18.3 to 28.3 percent of soybean oleic acid, 10.2 to 20.2 percent of glycerin, 3.8 to 7.8 percent of pentaerythritol, 17.6 to 21.6 percent of recycled terephthalic acid, 0.05 to 0.2 percent of color substration agent, 0.05 to 0.2 percent of antioxidant, 2.5 to 5.5 percent of phthalic anhydride, 3.2 to 7.2 percent of benzoic acid, 2 to 5 percent of dimethylbenzene, 18 to 30 percent of thinning agent and 0.05 to 0.2 percent of wetting dispersant. Terephthalic acid is adopted, and the unique chemical performance of the terephthalic acid endows the resin with high dryness and weather resistance; waste and inferior terephthalic acid produced by a petrochemical enterprise is utilized, so that the production cost of the resin is lower than that of alkyd resin produced by the conventional method; simultaneously, waste of the petrochemical enterprise is reduced, the environment is prevented from being polluted, and wastes are utilized to save energy and reduce emission.

Owner:HUIZHOU CHANGRUNFA PAINT

Hydrophobic and oleophyllic bi-component acrylic resin and preparation method and application thereof

The invention discloses a hydrophobic and oleophyllic bi-component acrylic resin and a preparation method and application thereof. The hydrophobic and oleophyllic bi-component acrylic resin comprises an A component and a B component, wherein the A component comprises 10 to 15 weight percent of hard monomer, 15 to 25 weight percent of higher alkyl methacrylates, 5 to 10 weight percent of fluorinated acrylic ester, 8 to 15 weight percent of cross linking monomer, 1 to 3 weigh percent of initiator, 10 to 25 weight percent of butyl acetate and 20 to 32 weight percent of dimethylbenzene; and the B component is an isocyanate curing agent of which the NCO content accounts for 10 to 23 percent of the total weight of the curing agent. The preparation method comprises a step of evenly mixing the A component with the B component which accounts for 14 to 32 weight percent of the A component to prepare the hydrophobic and oleophyllic bi-component acrylic resin. The bi-component acrylic resin has hydrophobic and oleophyllic performance and can serve as a coating for porous materials such as stainless steel metal meshes and filter paper to play a role in separating oil from water.

Owner:SOUTH CHINA UNIV OF TECH

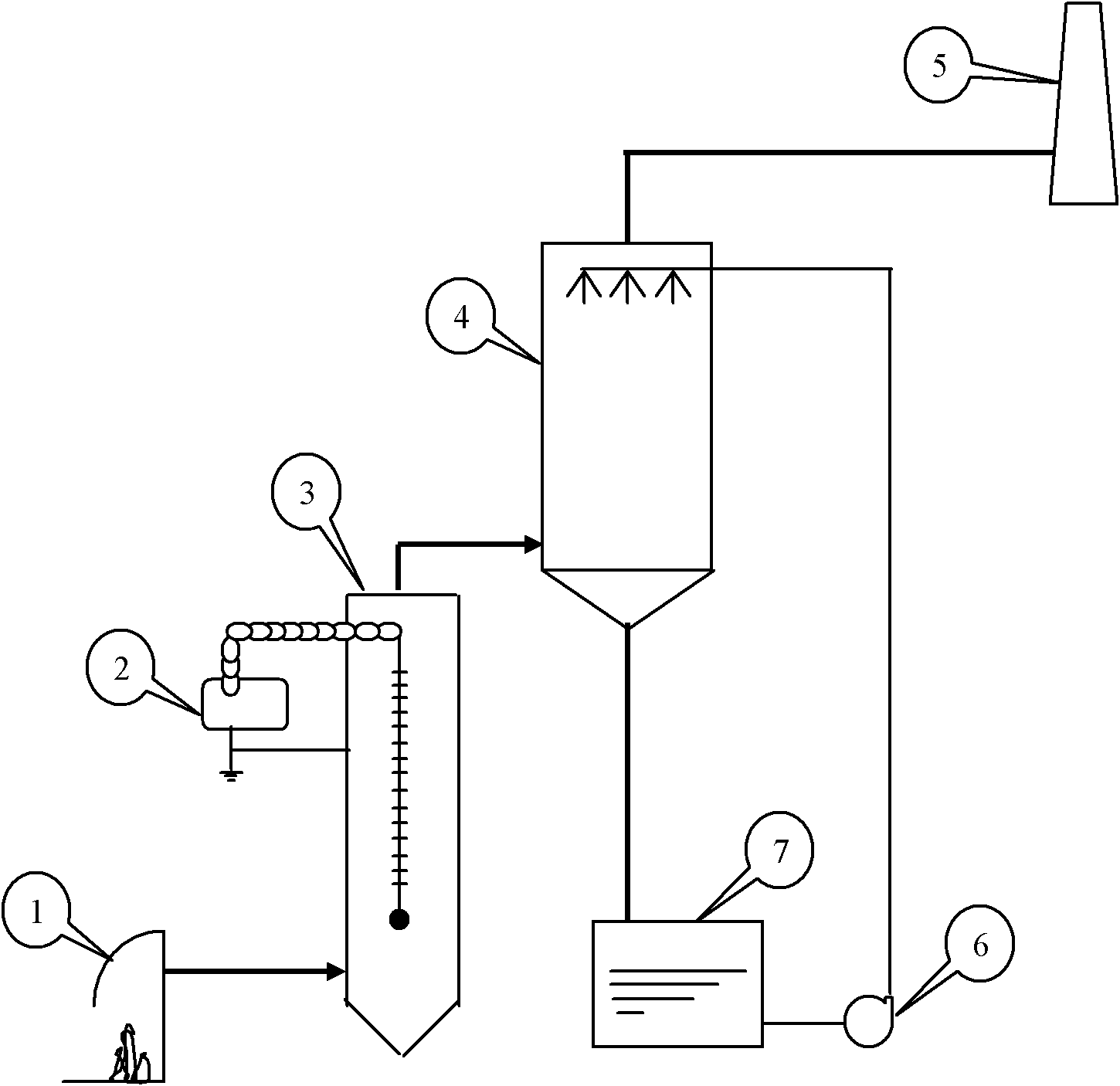

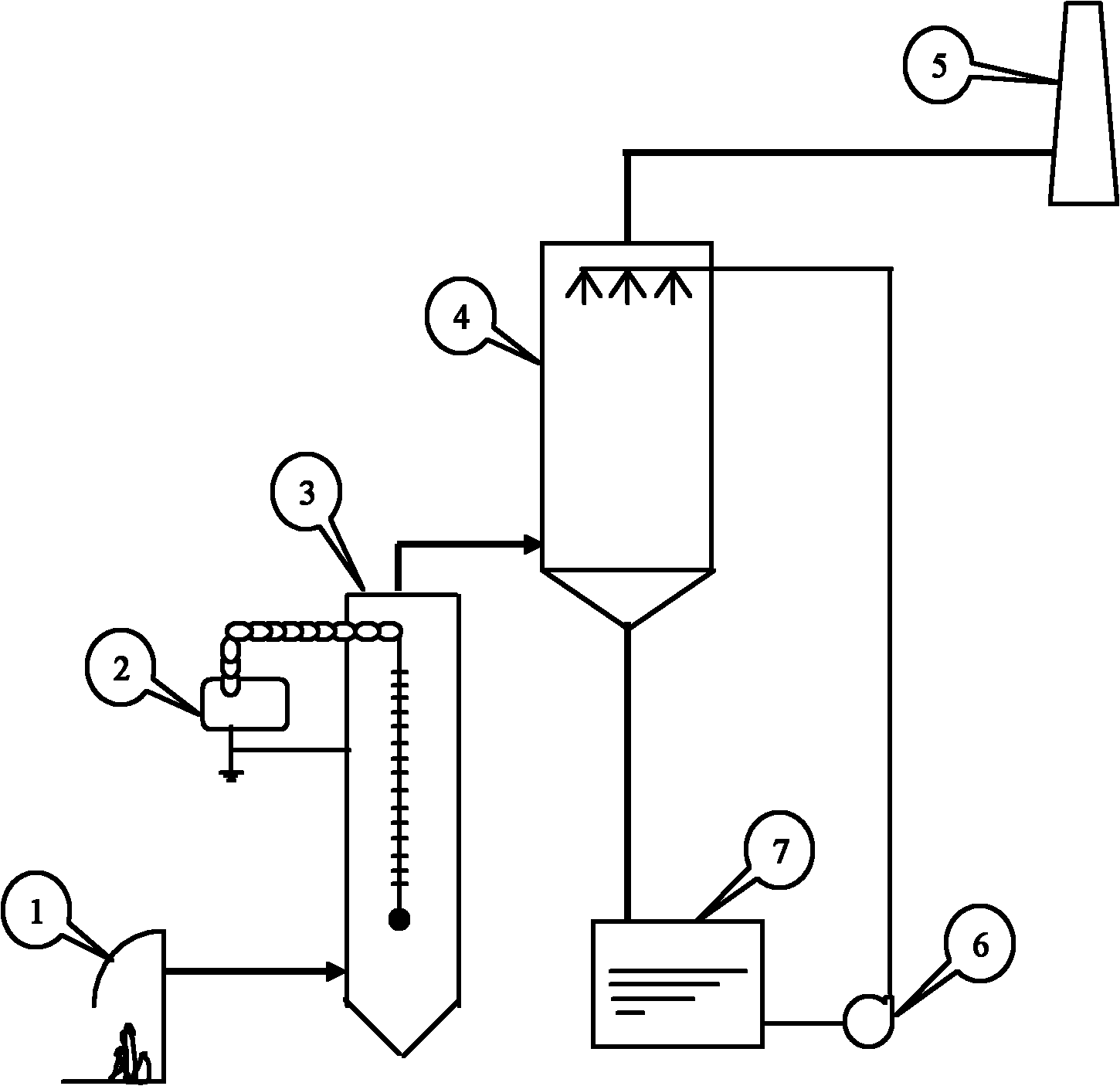

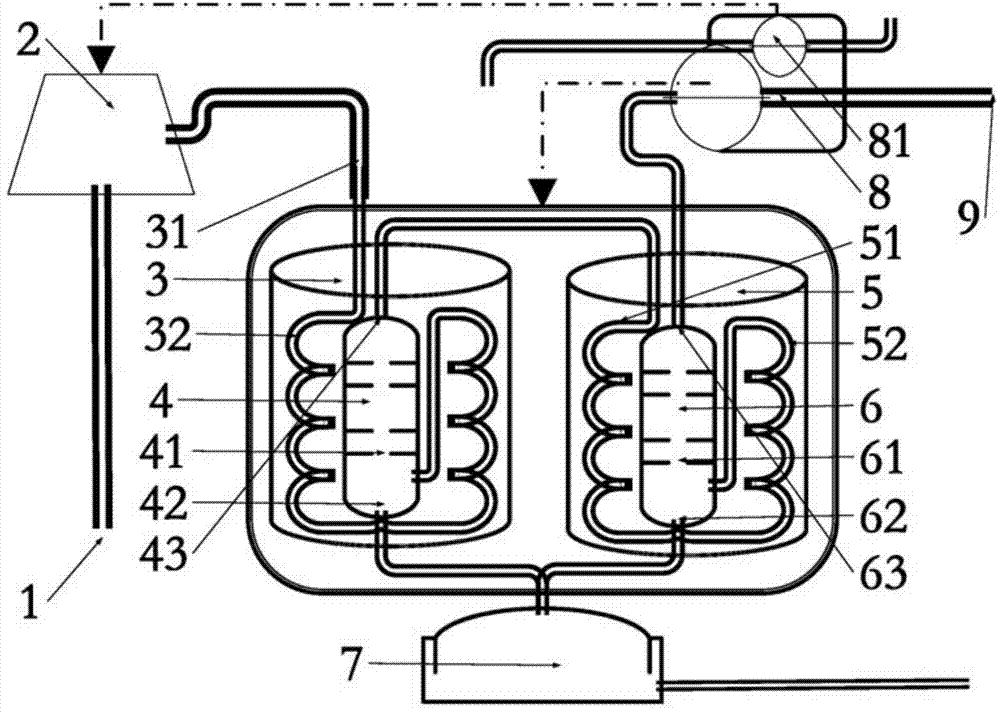

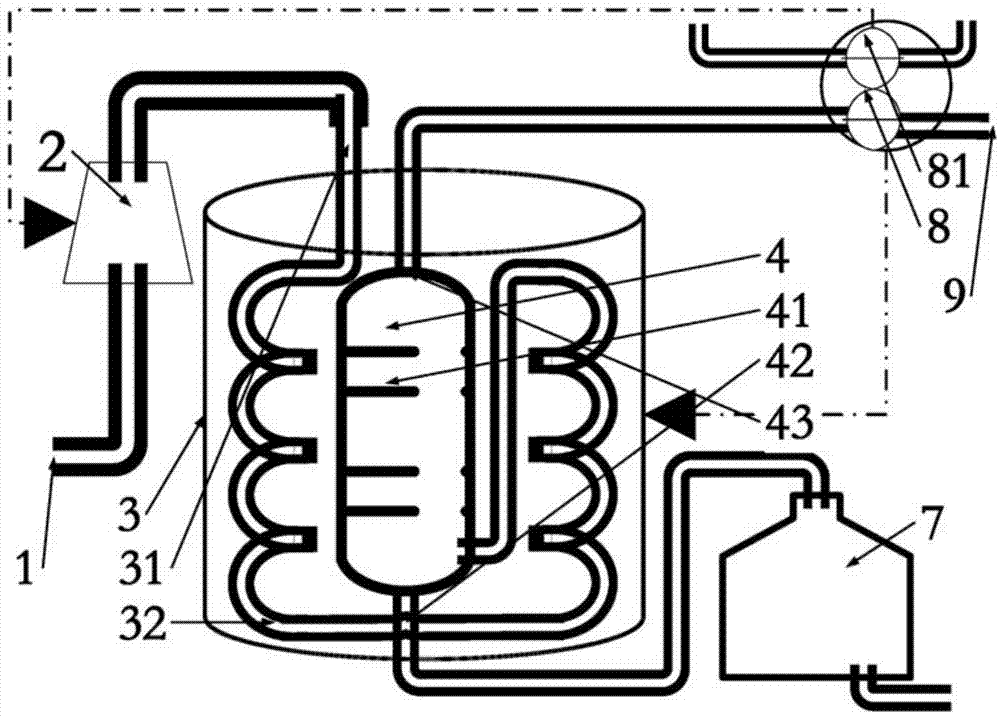

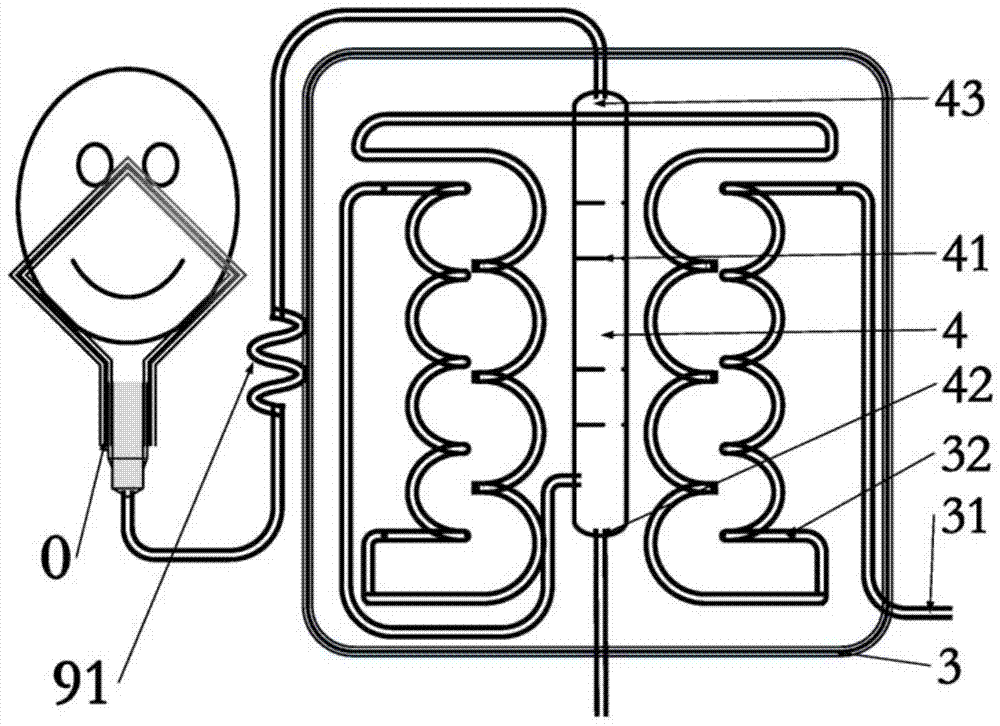

Method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms

ActiveCN102059047AAchieve purificationMeet emission requirementsDispersed particle separationAtmospheric airHigh energy

The invention discloses a method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms. After being collected, organic waste gas is sequentially treated through a low-temperature plasma reactor and a biological treatment reactor and finally exhausted to the atmosphere through a chimney. In the low-temperature plasma reactor, polycyclic aromatichydrocarbon, halogenated hydrocarbon, heterocycle compounds and an organic nitrile compound which are insoluble in water and nonbiodegradable are oxidized into low-carbon organic acid, alcohol, esterand other organic compounds which are soluble in water and biodegradable by utilizing substances with strong oxidizing property, such as O3, OH., H2O2, O. and high-energy electrons generated by high voltage discharge. In the biological treatment reactor, the organic acid, the alcohol, the ester and other organic compounds are further converted into CO2, H2O and other inorganic compounds under theaction of microorganisms. Through the treatment, the total purification efficiency of nondegradable organic compounds containing benzene, methylbenzene, dimethylbenzene, phenol and the like in waste gas can be up to over 90 percent.

Owner:山东航源环境科技有限公司

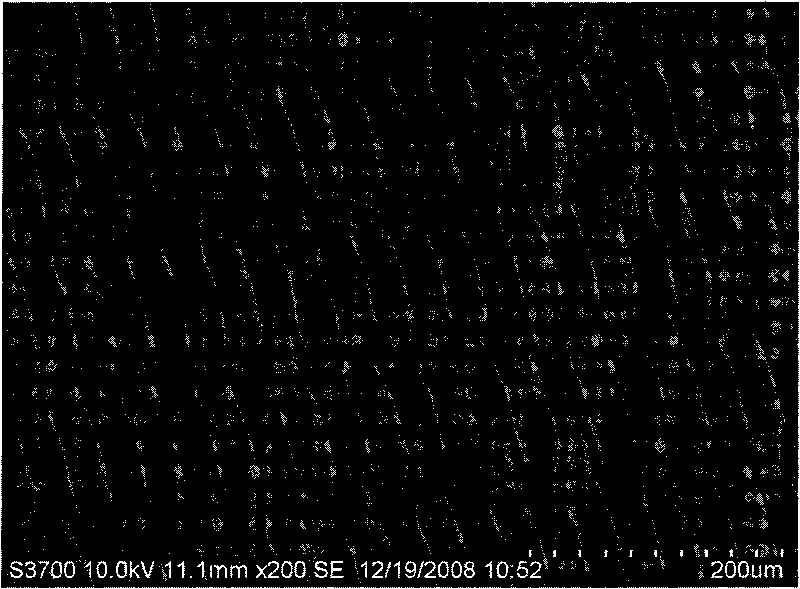

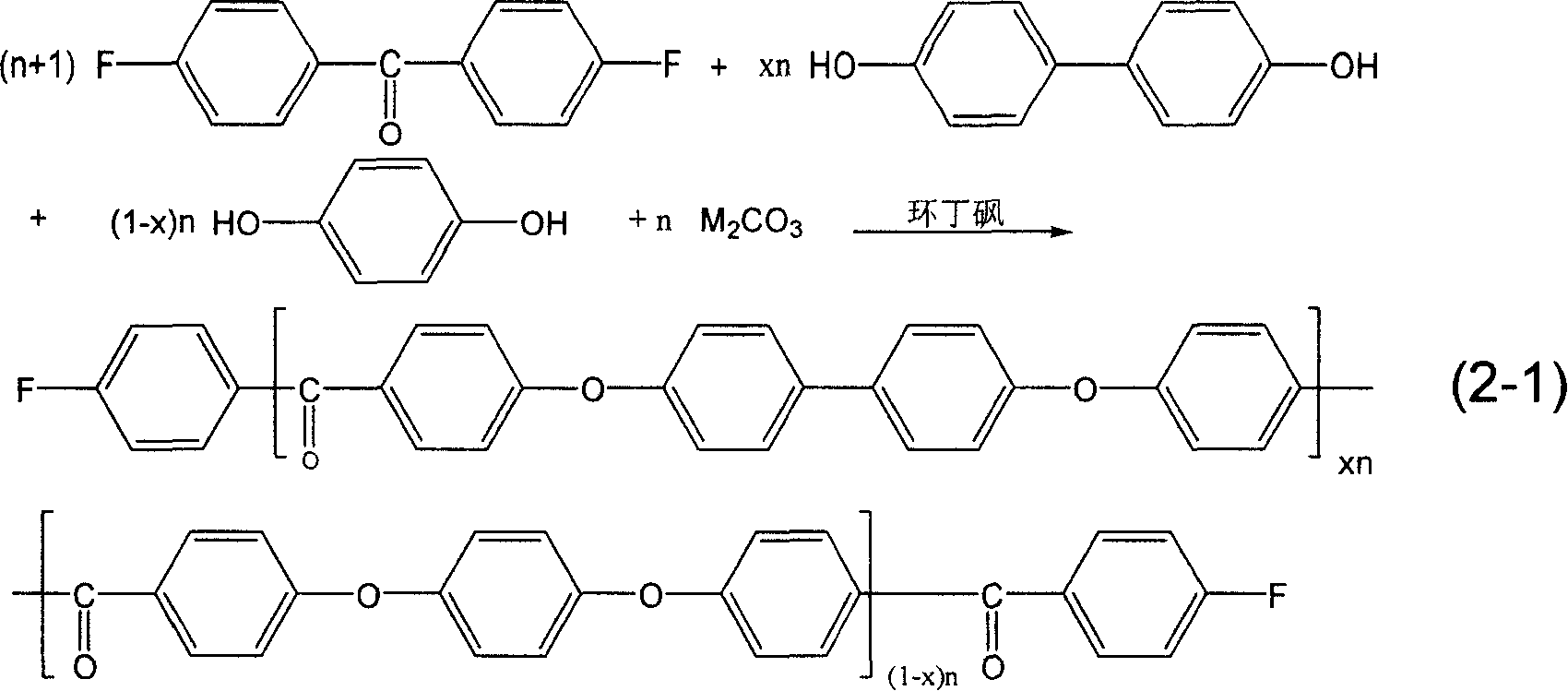

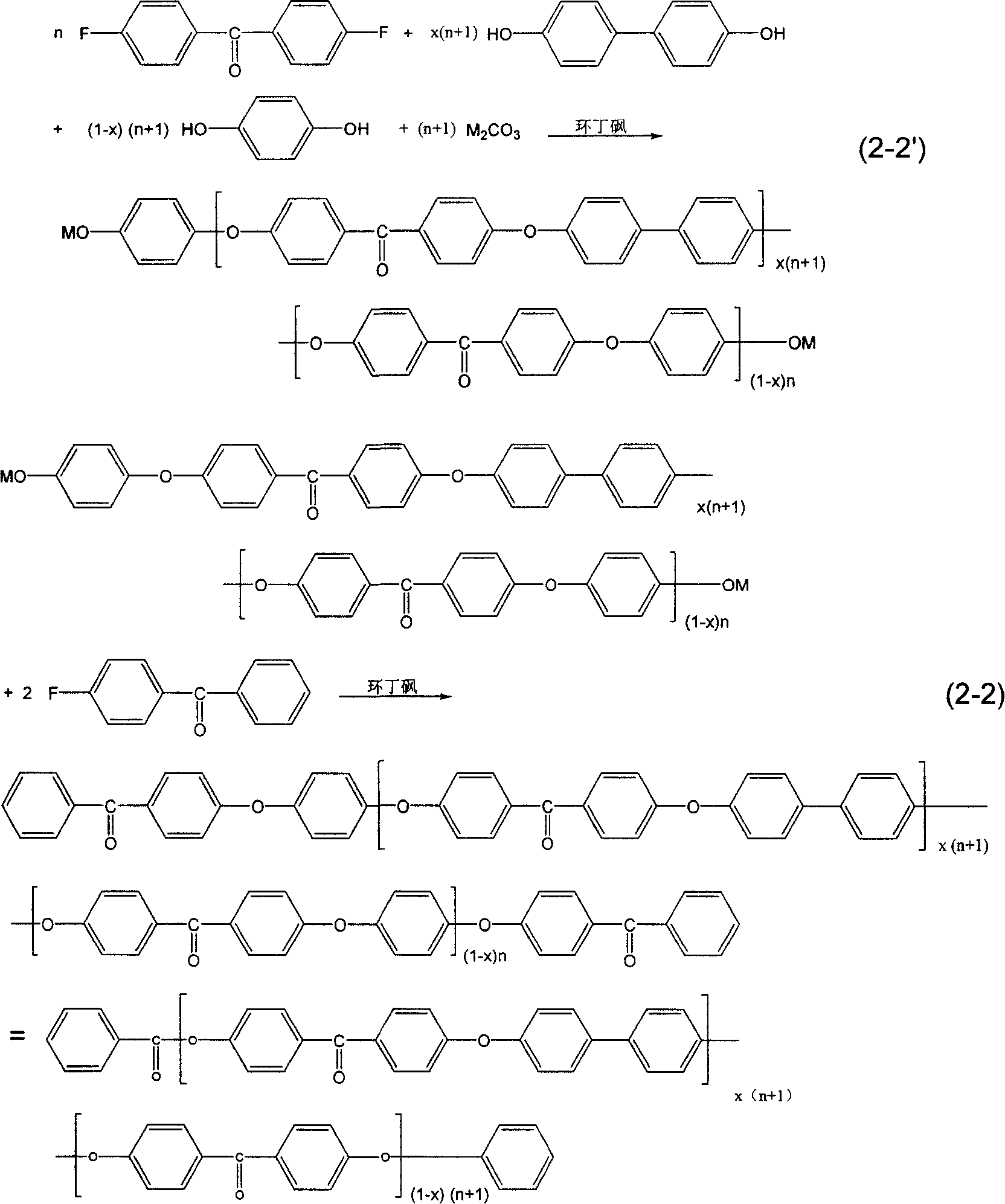

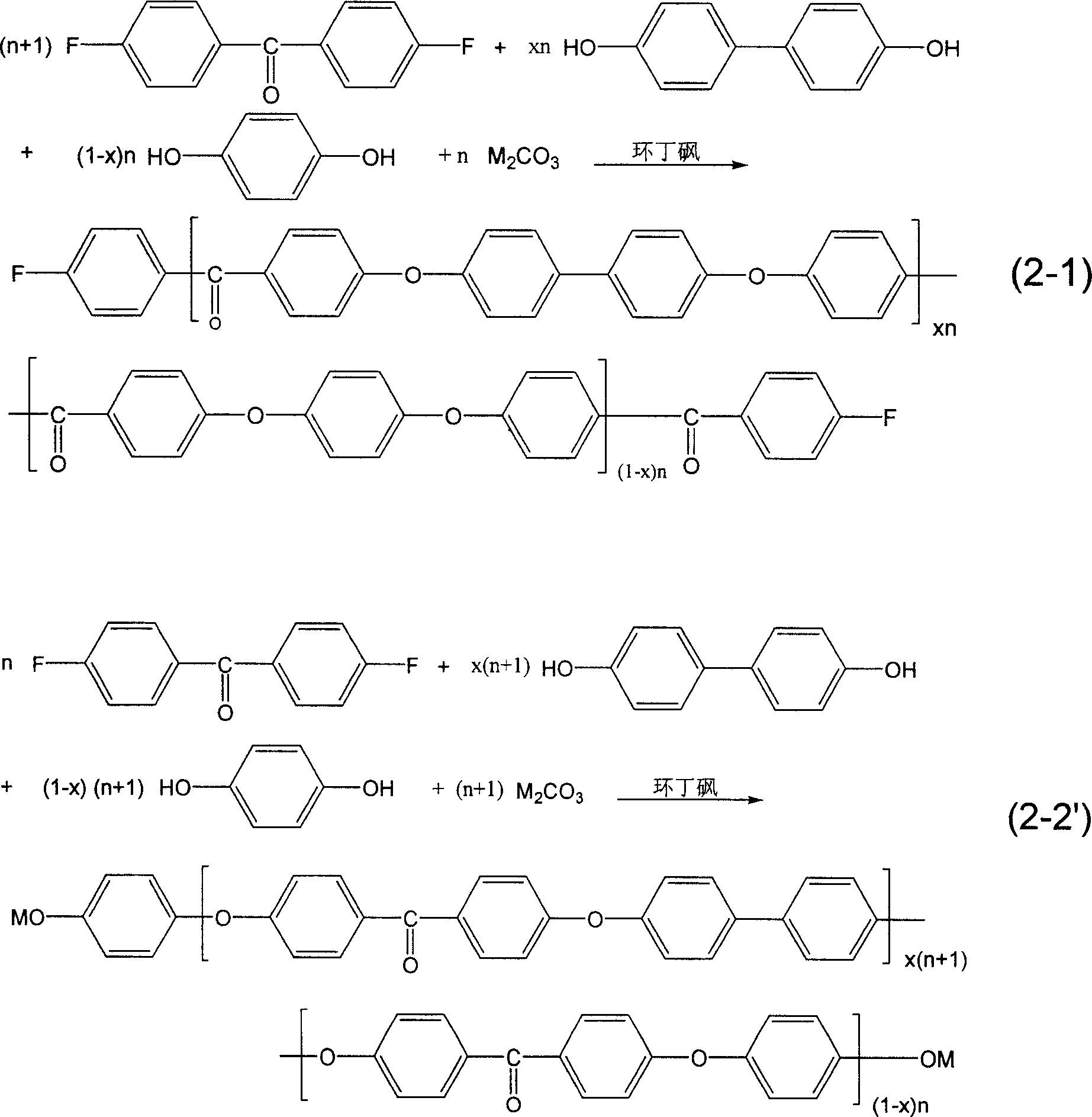

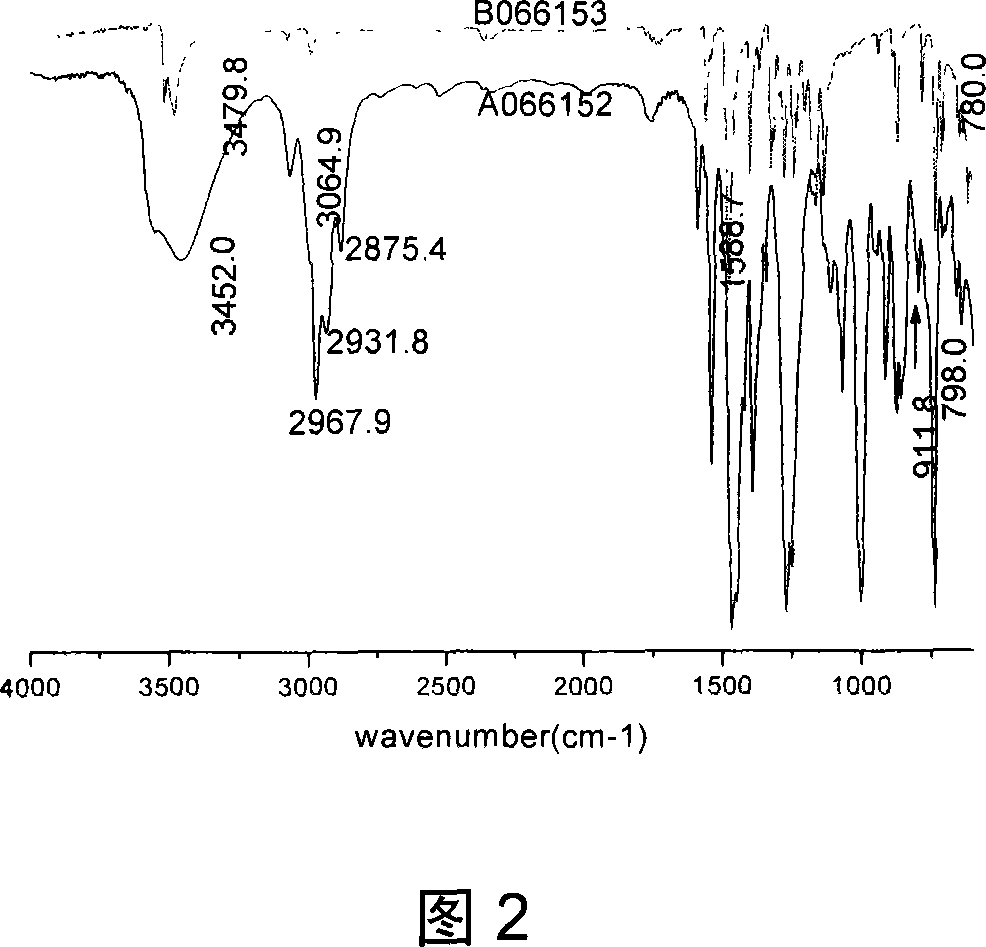

Synthesis method of ternary copolymer containing PEDEK and PEEK using sulfolane as solvent

The invention relates to a method for preparing polyetheretherketone and polyetheretherketone terpolymer by using sulfolane. It comprises following steps: the mole number of 4, 4'- difluoro diphenyl ketone is more than that of eldopaque and diphenol by 0.1-1%, the solid content in reaction system is 15-30%; filling dimethylbenzene with its mass being 10-20% of that of organic solvent, stirring, heating, adding mixed salt of alkali metal carbonate when monomer is totally dissolved and the temperature is between 75 to 85 Deg. C, reacting at constant temperature 230-260 Deg. C for 1-3 hours, stopping reaction, pouring product into cold water, cooling and disintegrating and filtering, boiling solid product with deionized water for several times, drying refined powder material in baking box, and getting said final product.

Owner:长春吉大特塑工程研究有限公司

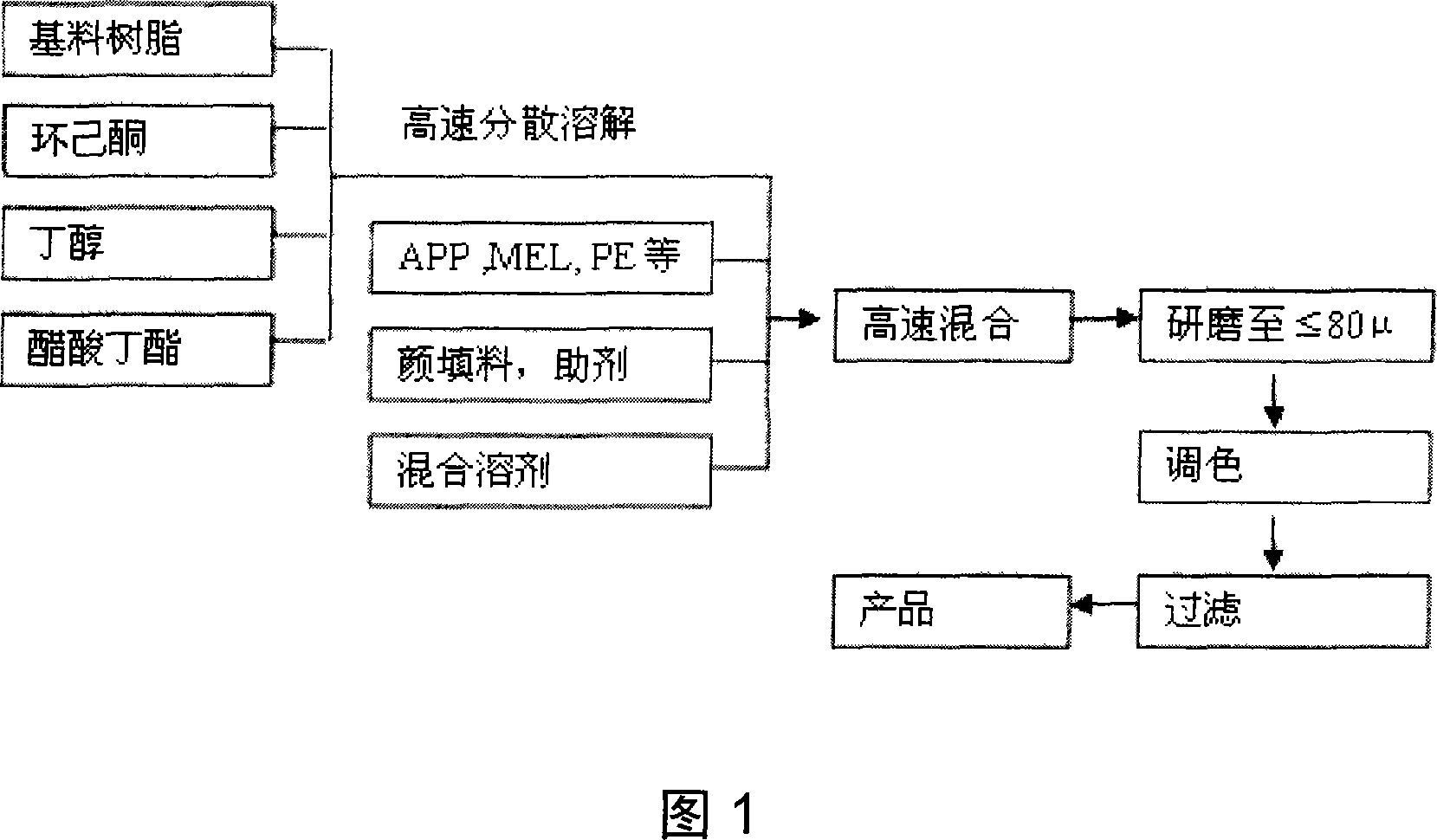

Fireproof paint for super-thin steel structure and preparation method thereof

InactiveCN101058693AStrong adhesionGood film formingFireproof paintsLiquid surface applicatorsTetrabromobisphenol APolyvinyl chloride

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof paint, which is characterized by the following: the allocation of tetrabromo-bisphenol A epoxide resin contains epichlorohydrin and tetrabromo-bisphenol A with weight rate at 1. 3-1. 5:1 and epichlorohydrin and sodium hydroxide with weight rate at 1. 0-1. 05:1; the allocation of fireproof painting is tetrabromo-bisphenol A epoxide resin and hyperchlorinated polyvinyl chloride with weight rate at 3: 1, polyphosphate, melamine, pentaerythritol with weight rate at 3:2:1, antimony trioxide and paraffin chloride with weight rate at 3:7, aluminium hydroxide and zinc borate smoke suppressor with weight rate at 10: 3. The method comprises the following steps: adding epichlorohydrin and tetrabromo-bisphenol A to the autoclave; mixing and heating at 90 Deg. C; adding caustic soda solution; keeping 7. 5 hours; washing and removing thylbenzene by heating;getting tetrabromo-bisphenol A epoxide resin; adding the mixed solvent to tetrabromo-bisphenol A epoxide resin and perchlorinated polyethylene; mixing and dissolving; adding ammonium polyphosphate, melamine, pentaerythrite, titanium dioxide, antimony oxide, aluminum hydroxide, zinc borate separately, adding chlorcosane; grinding after high-speed dispersing uniformly; mixing polyamide uniformly according to 10:1; getting the fire-proof paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

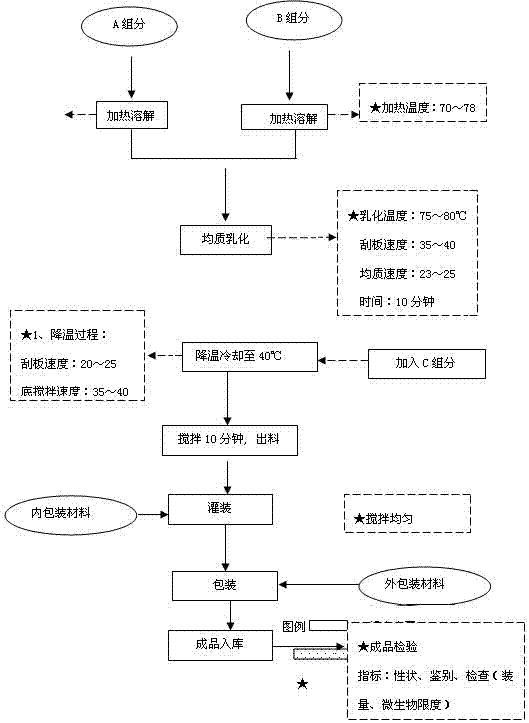

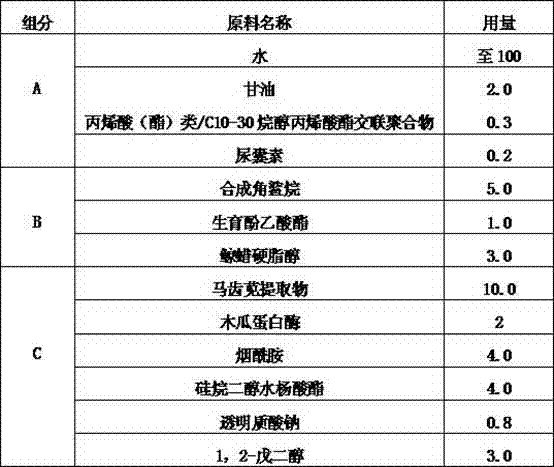

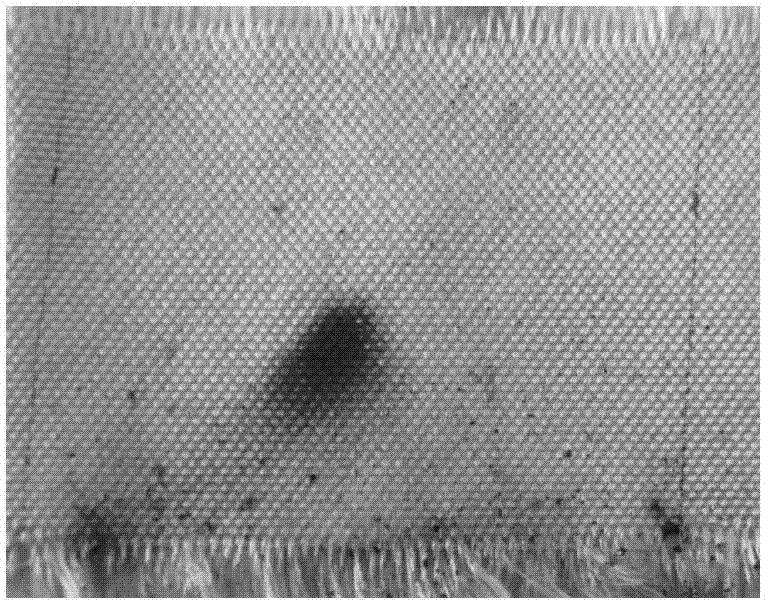

Functional skin care product containing purslane extractive and preparation method thereof

ActiveCN102764217AMild textureImprove securityCosmetic preparationsAntipyreticGlycerolPurslane extract

The invention is a functional skin care product containing purslane extractive. Raw materials of the functional skin care product include, by weight, 10 parts of purslane extractive, 1-2 parts of Prinsepia utilis rogle oil, 2-5 parts of glycerol, 0.3-0.5 parts of crylic acid (ester) / C10-30 alkanol acrylate cross-linked polymer, 2-3 parts of 1,2-pentanediol, 1-5 parts of synthesized squalane, 1-2 parts of tocopheryl acetate, 2-3 parts of cetostearyl alcohol, 0.1-0.2 part of allantoin, 0.3-0.8 part of sodium hyaluronate, 3-5 parts of Butyrospermum parkii butter, and 100 parts of deionized water. Or the Prinsepia utilis rogle oil and the Butyrospermum parkii butter are not added. By the aid of animal experiments, namely, mouse auricle swelling models due to dimethlbenzene, the functional skin care product containing purslane extractive is fine in anti-inflammation and anti-allergy effects, mild in nature and fine in safety, and is free of toxic reaction and anaphylaxis. The functional skin care product has an adjuvant therapy function to skin barrier recovery of common discosmetic dermatosis such as hormone dependent dermatitis and acne, and is fine in curative effect and safety.

Owner:YUNNAN BOTANEE BIO TECH GRP CO LTD

Weather-resistant epoxy polyurethane anticorrosive paint and preparation thereof

InactiveCN101298535AGood weather resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSiloxane

The invention relates to a weather resistant epoxy-polyurethane anti-corrosion coating and a manufacturing method thereof, which adds phenol-A epoxy resin, bisphenol-F epoxy resin, hydroxyl contained saturated polyester resin and fluorocarbon resin into the mixed solvent of dimethylbenzene, n-butyl acetate, methyl isobutyl ketone and butanone; then adds rutile type titanium pigment, saponite, sericite in powder, polyacrylate co-polymer, polymethyl alkyl siloxane, benzotriazole, gas phase silica and iso-caprylic acid znic to make the fluid A of the weather resistant epoxy-polyurethane anti-corrosion coating while adds fatty group polyisocyanate into the mixed liquor of anhydro-dimethylbenzene and the n-butyl acetate to make fluid B, and mix the two components during application. The invention can be applied to the preservation of the surfaces of outdoor steel structures, pipes and concrete requiring weather resistance, light aging resistance and acid, alkali and salt corrosion resistance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

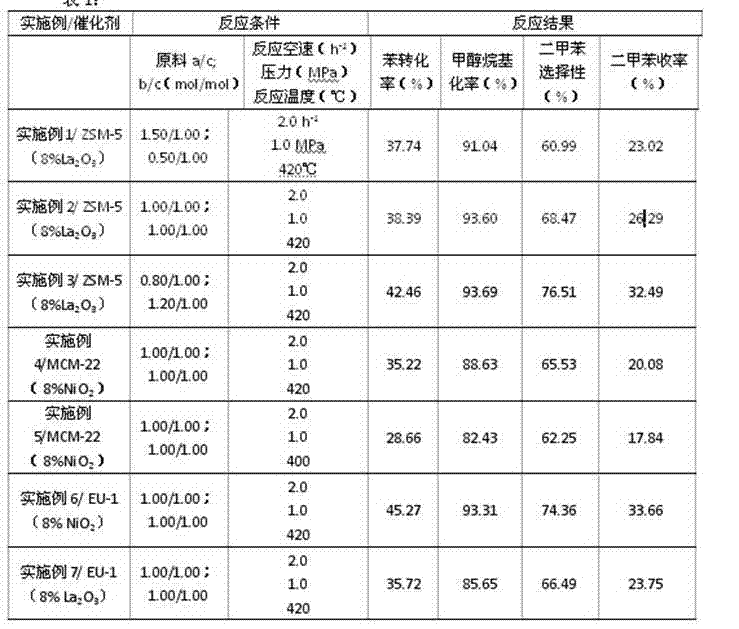

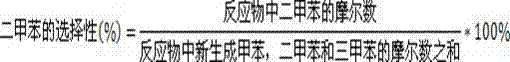

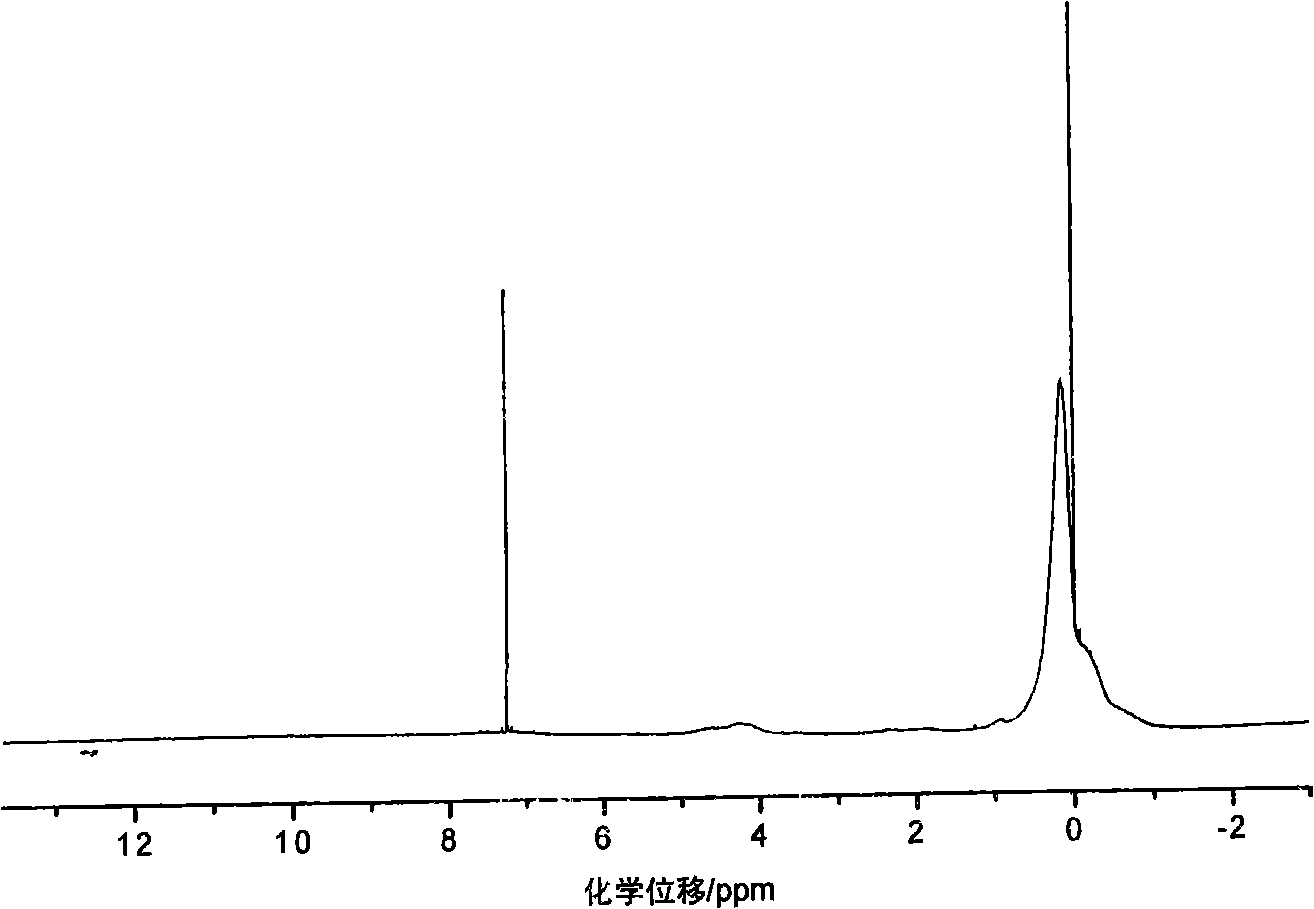

Method for high selectively synthesizing dimethylbenzene through benzene and methanol alkylation reaction

ActiveCN102964201AImprove reaction stabilitySuppress generationHydrocarbon by hydrocarbon and non-hydrocarbon condensationBulk chemical productionPtru catalystReaction temperature

The invention relates to a method for high selectively synthesizing dimethylbenzene through benzene and methanol alkylation reaction. The method takes the benzene as a raw material a, a toluene is taken as a raw material b, the methanol is taken as a raw material c, according to the molar ratio, a / c equals to 0.50-3.00 / 1.00, b / c equals to 0.60-3.00 / 1.00, under the conditions that the reaction temperature is between 380 and 480 DEG C, the reaction pressure is between 0.50 and 6.0 mega pascals, the reaction space velocity is between 0.5 and 5.0 h<-1> and the carrier gas is H2, N2 or CO2, the dimethylbenzene is produced in a fixed bed reactor under the catalysis of molecular sieve based catalysts, the catalysts are one or a plurality of molecular sieves of zeolite socony mobile-5 (ZSM-5), USY, mobile composite of matter (MCM)-22 or EU-1, a load metallic oxide is Mo, Ni or La metallic oxide, and the load of the metallic oxide is 0.50-10.00%. The method utilizes the benzene with relative surplus capacity and the inexpensive methanol to produce the dimethylbenzene with high industrial added value. The appropriate molecular sieve based catalyst is adopted, the utilization ratio of the methanol alkylation reaction for high selectively synthesizing the dimethylbenzene cannot be less than 90%, and the catalyst stability can satisfy industrial application requirements. Moreover, the toluene is added into the reaction raw materials, so that toluene byproducts can be inhibited from being produced; and in addition, an H2, N2 or CO2 carrier gas atmosphere is adopted, so that the reaction stability of the catalyst is enhanced.

Owner:TONGJI UNIV

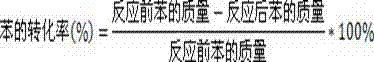

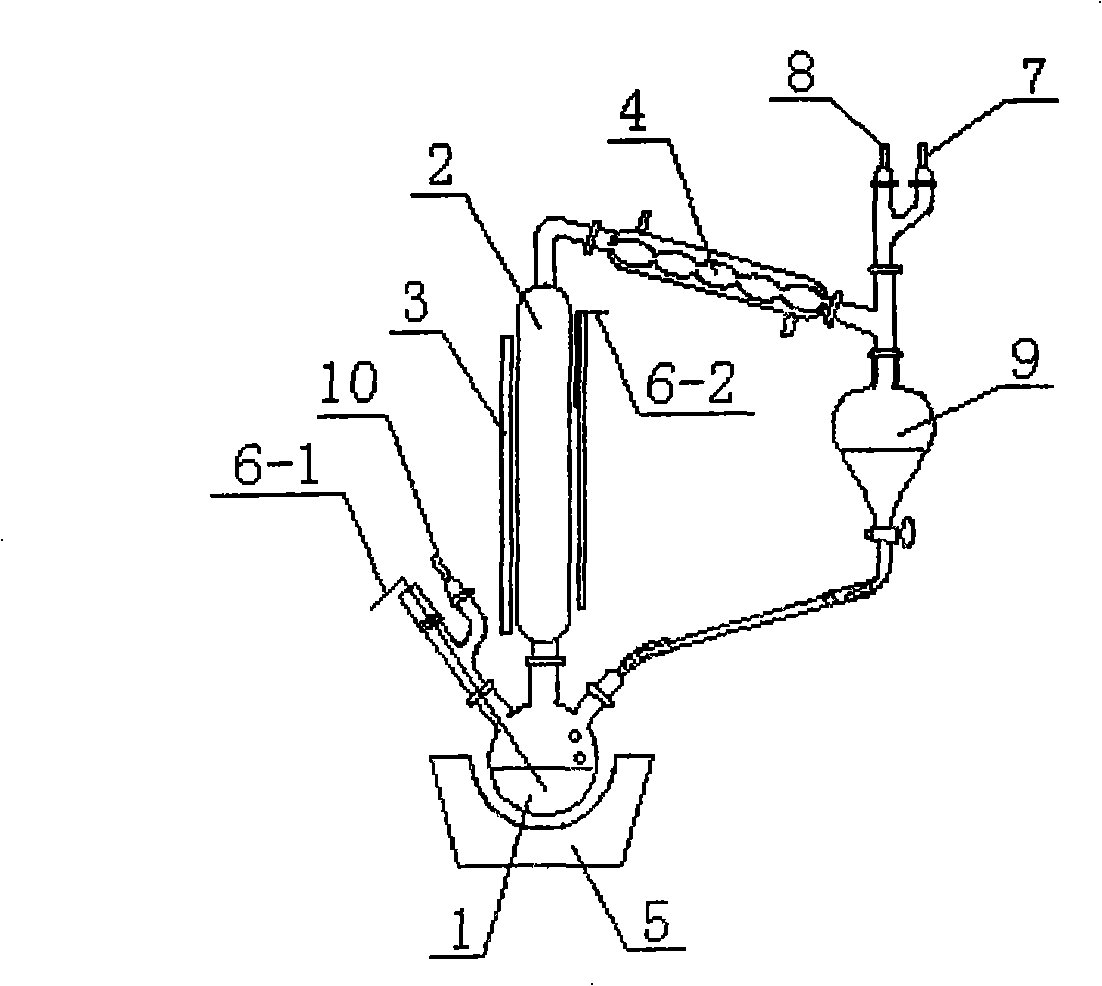

Method for manufacturing hafnium containing SiC ceramic precursor

The invention provides a method for preparing a SiC ceramic precursor containing hafnium, comprising the following steps that: (1) a low molecular weight polymer containing silicon in the main chain is put inside a three-neck flask, and added with hafnium organic compound or chloride the mass of which is 0.5 to 20wt% of the low molecular weight polymer; (2) under the protection of Ar or N2 or the mixture of the two, the temperature of the three-neck flask is increased to between 350 and 500 DEG C according to the temperature increasing rate of 0.1 to 5 DEG C per minute, the temperature of a cracking post is controlled between 450 and 550 DEG C, the pyrolysis recomposition reaction is performed for 0.3 to 30 hours, the PHCS coarse product is produced after the cooling process; and (3) the coarse product is dissolved in the dimethylbenzene and is filtered, the filtrate is decompressed, distilled and cooled at a temperature of between 300 and 390 DEG C. The raw materials are widely available, the reaction process is easy to control, the device is simple, the product has high purity, the re-forming property is good, the super high temperature performance is good; the large-scale industrial production is easy to realize; and the ceramic fiber prepared has good anti-oxidation performance.

Owner:NAT UNIV OF DEFENSE TECH

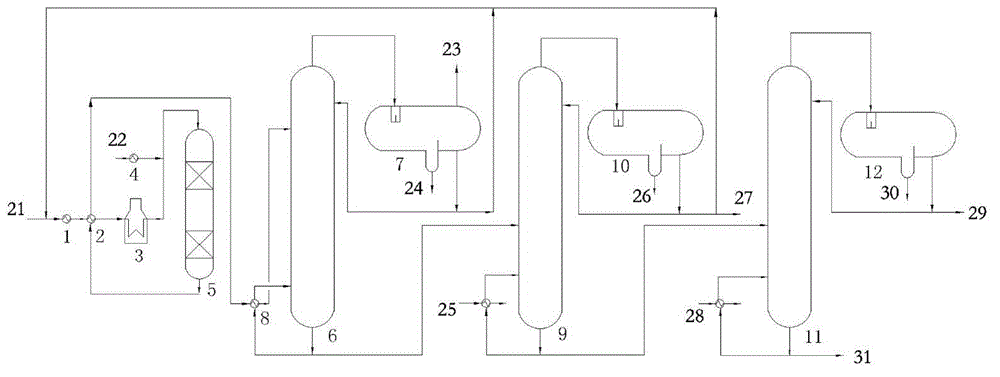

Method for dimethylbenzene and trimethylbenzene by alkylating benzene and methanol

InactiveCN102746080AShort processThe equipment is not complicatedHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical recyclingBenzeneToluene

The invention relates to a method for dimethylbenzene and trimethylbenzene by alkylating benzene and methanol, which comprises steps as follows: (1) raw material benzene is mixed with cyclic benzene, methylbenzene and partial dimethylbenzene recovered from rectification, the mixture is heated and gasified to reaction temperature, the mixture and methanol enter an alkylating reactor, and alkylating reaction is performed in the presence of an acidic catalyst to obtain a product mixture of methylbenzene, dimethylbenzene, trimethylbenzene and the like; the unreacted benzene and generated methylbenzene and partial dimethylbenzene return to continue reaction with methanol so as to generate C8+ aromatic hydrocarbons; (2) the mixed aromatic hydrocarbons from the alkylating reactor enter a methylbenzene removal tower to be rectified and separated, the mixture of benzene, methylbenzene and water at the tower top is cooled and subjected to oil-water separation, the oil phase returns to the alkylating reactor for circular reaction, and the water phase is recycled after treatment; oil at the tower bottom enters a dimethylbenzene rectification tower to be rectified and separated, part of mixed dimethylbenzene obtained from the tower top returns to the reactor, and the rest is used as the product; and oil at the tower bottom enters a trimethylbenzene rectification tower to be rectified, thereby obtaining the mixed trimethylbenzene product at the tower top.

Owner:NINGXIA BAOTA PETROCHEM GROUP

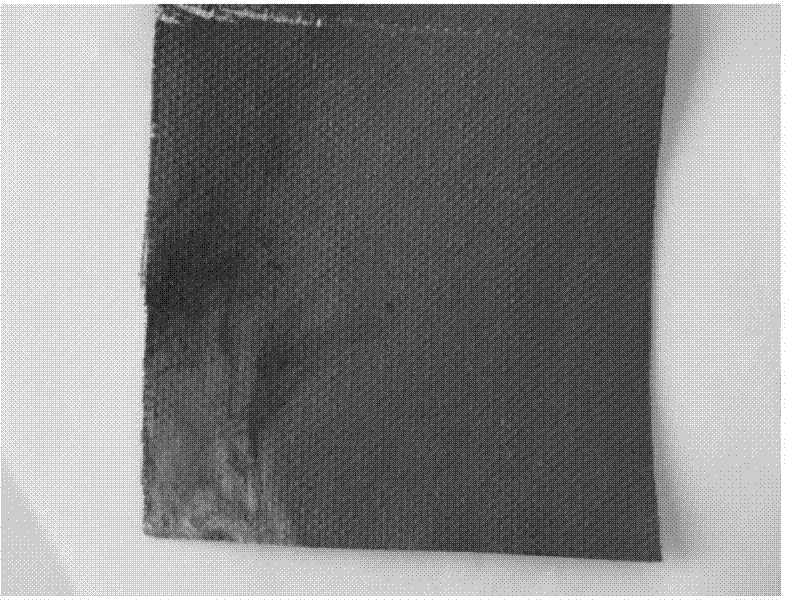

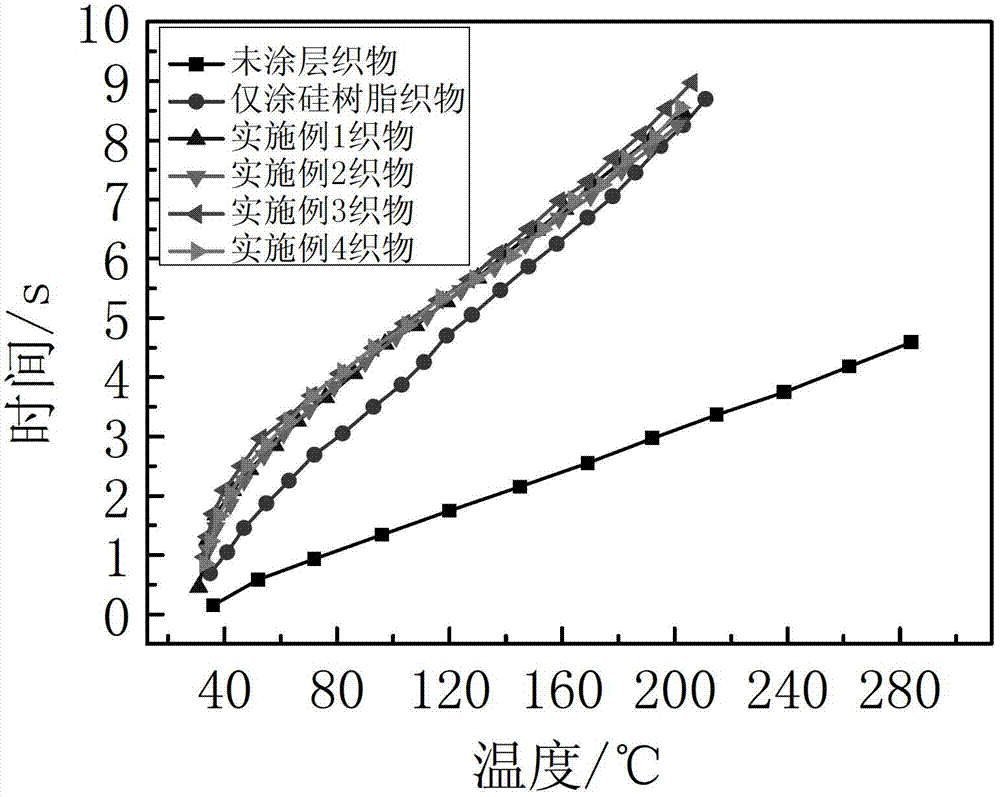

Heat-insulating and ablation-resistant glass fiber fabric and preparation method thereof

ActiveCN103205896AImprove heat resistanceImprove crack resistanceFibre treatmentResin coatingEngineering

The invention provides a heat-insulating and ablation-resistant glass fiber fabric and a preparation method thereof, belonging to the technical field of thermal protection fabrics and preparation thereof. The heat-insulating and ablation-resistant glass fiber fabric product comprises a fabric layer and coating layers on the front and back surfaces of the fabric layer, wherein the thicknesses of the coating layers on the front and back surfaces of the fabric layer are controlled at 30-80 micros; the fabric layer is made from glass fiber fabrics; the coating layers are composite organic silicon resin coating layers which are prepared by mixing an organic silicon resin solution, white carbon black, mica powder and the like in certain percentage by weight; a solute of the organic silicon resin solution is phenyl methyl silicone, a solvent of the organic silicon resin solution is dimethylbenzene, toluene or a mixture of the two, and the mass ratio of the solvent to the solute is 1:1; and a preparation method of a composite organic silicon resin coating layer solution comprises the following steps of: sequentially adding the white carbon black, the mica powder, wollastonite in powder and metallic oxide into the organic silicon resin solution, and stirring to ensure that the substances are uniformly dissolved. The heat-insulating and ablation-resistant glass fiber fabric is simple in process, easy to operate, and excellent in heat resistance, weather resistance, insulating property, reinforcement performance, scrubbing resistance and weathering resistance.

Owner:赵晓明 +1

Modified polypropylene, process for preparing modified polypropylene, modified polyropylene composition and foamed product

A modified polypropylene has a melt flow rate of 0.1 to 10 g / 10 min, a melt tension of 3 to 20 g and a gel fraction, as determined by boiling paraxylene extraction, of 0.01 to 25% by weight. The modified polypropylene, a process for preparing the modified polypropylene, and a modified polypropylene composition containing the modified polypropylene are capable of producing a foamed product having excellent foam properties and food hygienic qualities. The foamed product obtained from the modified polypropylene or the modified polypropylene composition is lightweight, highly rigid and excellent in chemical resistance and food hygienic qualities, and hence it can be used for food packaging containers and trays, particularly containers of noodles or ice cream and trays of fish or meat, for which polystyrene has been heretofore used.

Owner:MITSUI CHEM INC

Method for synthesizing liquefied petroleum gas and BTX aromatics by butyl alcohol

InactiveCN103131456AReduce dependenceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsNitrogen gasPolymerization

The invention provides a method for synthesizing liquefied petroleum gas and BTX aromatics by butyl alcohol. The method for synthesizing the liquefied petroleum gas and the BTX aromatics by the butyl alcohol comprises the steps that butyl alcohol raw materials or mixed reaction raw materials of butyl alcohol raw materials and nitrogen are put into a reaction area; the reaction raw materials are converted into a liquid-phase aromatic hydrocarbon compound rich in benzene, methylbenzene and dimethylbenzene under the action of catalytic agents and through dehydration reaction and polymerization and aromatization reaction; the liquid-phase aromatic hydrocarbon compound is converted into a liquefied petroleum gas component rich in dimethylmethane, hydride butyl and iso-butane through hydrogen transfer and cleavage reaction; and the liquid-phase aromatic hydrocarbon compound and the liquefied petroleum gas component are recovered through gas-liquid separation. According to the method for synthesizing the liquefied petroleum gas and the BTX aromatics by the butyl alcohol, non-fossil resources are adopted as raw materials, the aromatic hydrocarbon compound (the benzene, the methylbenzene and the dimethylbenzene) is produced under the condition that the catalytic agents exist, and dependence on disposable consumption of fossil raw materials (hydrocarbon, naphtha, and diesel oil) is reduced for the production of the aromatic hydrocarbon compound.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

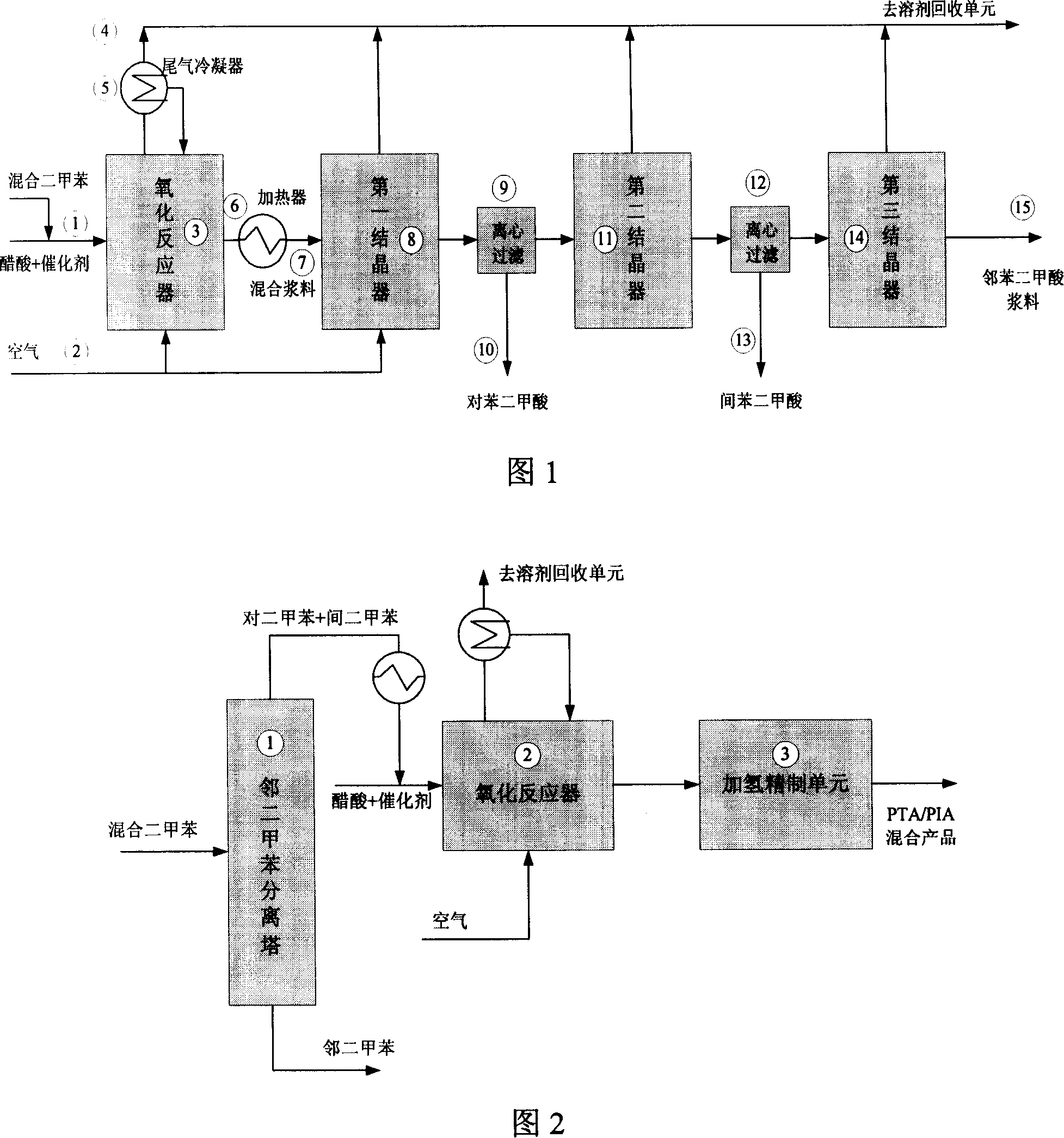

Method for producing benzene dicarboxylic acid by mixed dimethylbenzene cooxidation

InactiveCN1962598AReduce separation costsSimple processOrganic compound preparationCarboxylic compound preparationCarboxylic acidSlurry

The invention discloses a manufacturing method of benzene dicarboxilic acid through co-oxidizing blended xylene, which comprises the following steps: adding blended xylene, acetate solvent, cobalt, magnesium, bromine three-element catalyst into oxidizing reactor; blowing air or oxygen gas; oxidizing at 150-220 Deg C under 0.5-2.5Mpa for 30-150 min; obtaining mixed benzene dicarboxilic acid slurry; separating to obtain the mixed benzene dicarboxilic acid product or pure terephthalic acid, isophthalic and phthalic acid through multi-grade crystallizing, separating and purifying.

Owner:ZHEJIANG UNIV

Preparation method for thermoset high temperature resistant methyl phenyl silicone resin

The invention discloses a preparation method for thermoset high temperature resistant methyl phenyl silicone resin, which relates to the technical field of resin preparation and comprises the steps of utilizing toluene or dimethylbenzene or mixed solution of the toluene and dimethylbenzene to serve as a solvent, utilizing methyl trichlorosilane, dichlorodimethylsilane and methylphenyldichloros as monomer raw materials, dropping mixed solution of acetone and water into the raw materials under the condition of ice-water bath, ensuring that the dropping is finished within 3-5 hours, obtaining a prepolymer of the methyl phenyl silicone resin, performing condensation and curing on the obtained prepolymer above 150 DEG C after pressure of the prepolymer is reduced and the prepolyme is concentrated, the adopted condensation catalyst is caprylate or naphthenate, particularly is stannous octoate, zinc isoocatanoate, cobalt naphthenate and dibutyltin dilaurate. The resin is semi-transparent hard or elastic solid, can not be dissolved or fused, and can be resistant to high temperature above 200 DEG C, and can be used as silicon rubber or a plastic filler.

Owner:JIANGSU UNIV

Anti-rust primer for elementary surface treatment of steel material, and manufacturing method thereof

InactiveCN101298536AImprove adhesionImprove rust resistanceLiquid surface applicatorsAnti-corrosive paintsPolyesterLacquer

The invention relates to an antirust primer with rust and with elementary surface treatment used for steel materials and a manufacturing method, wherein, fluid A is made by mixing, agitating and grinding bisphenol-A epoxy resin, dimethylbenzene, n-butyl alcohol, tannin, precipitated barium sulfate, zinc phosphate, saponite, iron oxide red, simethicone, polyester modified polyphosphonate compound and polyamide wax micropowder, while fluid B is made from polyamide resin, the dimethylbenzene and the n-butyl alcohol; when in use, mix and cure the fluid A and the fluid B to form the coating film. The antirust primer with rust and with elementary surface treatment has excellent adhesion and corrosion resistance, which can be coated on steel surfaces with uneven rust, solid oxide scale residuals or old paint, and can be directly used and matched as a primer with other finish paints without using any other primers.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Nano SiO2-organosilicon coating and preparation method thereof

The invention relates a nanometer SiO2- organosilicon coating and preparation method. The coating comprises the 60-82% organosilicon resin, 3-10% nanometer SiO2, 5-15% dimethylbenzene, 3-8% toluene, 3-6% butyl acetate, 0.2-0.6% dispersing agent, 0.1-0.3% levelling agent, 0.2-0.4% defoaming agent, and 3-10% talcum powder. The method comprises the following steps: 1 weighing nanometer SiO2, adding dimethylbenzene, dispersing agent and butyl acetate, disperse with ultrasonic, and getting nanometer SiO2 slurry; 2 weighing organosilicon resin, adding defoaming agent and dispersing agent, then adding nanometer SiO2 sluury and talcum powder, dispersing and grinding; 3 adding left resin, solvent and adjuvant, and dispersing. The invention can improve the erosion-resisting characteristics, protect material, and extend the life.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Synthetic method of acrylic resin

ActiveCN103130949AImprove adhesionExcellent physical and chemical propertiesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention discloses a synthetic method of acrylic resin. The synthetic method comprises the following steps of: (1) pumping dimethylbenzene, methylbenzene and butyl acetate into a reaction kettle, and reserving little dimethylbenzene for flushing pipelines; (2) dissolving an initiator 1 in methyl methacrylate, then adding styrene, butyl acrylate, acyclic acid and one third of hydroxy-propyl acrylate for mixing with the mixed solvent in the step (1) to form a mixed monomer, and pumping into a header tank; (3) opening a condenser, heating, maintaining refluxing, dropwise adding the mixed monomer in the step (2) at 120-125 DEG C, completing dropwise addition within 2.5-3 hours, after one half of mixed monomer is dropwise added, adding another one third of hydroxy-propyl acrylate to the mixed monomer according to the formula amount, after one half of new mixed monomer is dropwise added, adding the rest of one third of hydroxy-propyl acrylate according to the formula amount, continuing dropwise addition, and carrying out heat preservation for 2 hours after the dropwise addition of the mixed solution is ended; and (4) refilling an initiator 2 in the solution in the step 3, carrying out heat preservation for 2 hours, refilling an initiator 3, carrying out heat preservation for 2 hours, and closing water of the condenser.

Owner:西安经建油漆有限责任公司

Method and device for purifying air pollution

The invention provides a method and a device suitable for completely and infinitely purifying indoor or closed space polluted air. The method and the device are characterized in that a pollutant component is separated and removed through a phase change method, air is circularly introduced into a phase change device to generate phase change on the pollutant component in a gas phase to form liquid or solid so as to separate the pollutant component from a clean gas phase component, the pollutant component is stored and treated, and the clean air is continuously conveyed back into the original space. The technology does not need to use, consume or change any active material nor supplement external air, only electric energy or potable refrigeration equipment is adopted to infinitely remove any pollution component in air necessary for human respiration, and the pollution component includes but not limited to carbon monoxide, ammonia, formaldehyde, sulfur dioxide, acetaldehyde, acrolein, benzene, toluene, ethyl benzene, dimethylbenzene, styrene, benzopyrene, volatile organic compounds, PM2.5 and nano particles. By reforming an existing refrigeration component, the technology can be used for purifying various civil, industrial, military and other indoor or closed space polluted air.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High transparency scratch-resisting matt clear paint

ActiveCN103131321AImprove the decorative effectImprove protectionPolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses high transparency scratch-resisting matt clear paint which is composed of a host agent, a curing agent and a diluent agent. The host agent comprises 65.5 % - 75.5% of short oil alkyd resins, 16 % - 25 % of solvent, 0.1 % - 0.3 % of antifoaming agents, 0.1 % - 0.3 % of flatting agents, 0.1 % - 0.5 % of anti-settling agents, 0.1 % - 0.3 % of dispersing agents, 1 % - 3 % of scratch-resisting assistant agents, and 4 % - 8 % of delustering agents. The curing agent comprises 40 % - 50 % of toluene diisocynate (TDI) trimer, 10 % - 20 % of TDI- hexamethylene diisocyanate (HDI) mixed trimer, 20 % - 30 % of TDI- trimethylolpropane adduct, and 20 % - 30 % of butyl acetate. The diluent agent comprises 40 % - 50 % of butyl acetate, 20 % - 30 % of dimethylbenzene, and 20 % - 30 % of propylene glycol methyl ether acetate. The high transparency scratch-resisting matt clear paint is good in transparency and scratch-resisting performance, and is easy to process.

Owner:安徽名士达新材料有限公司

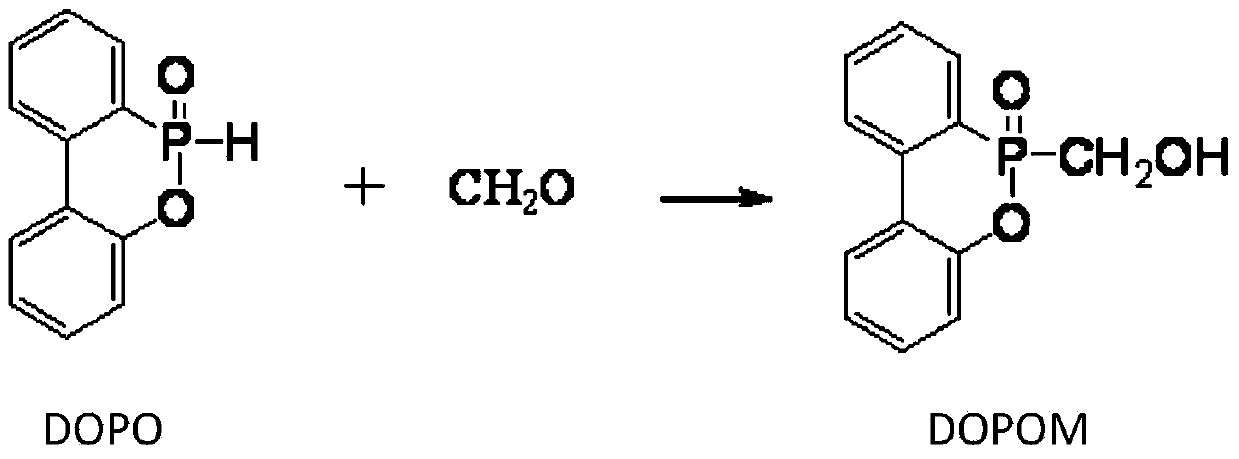

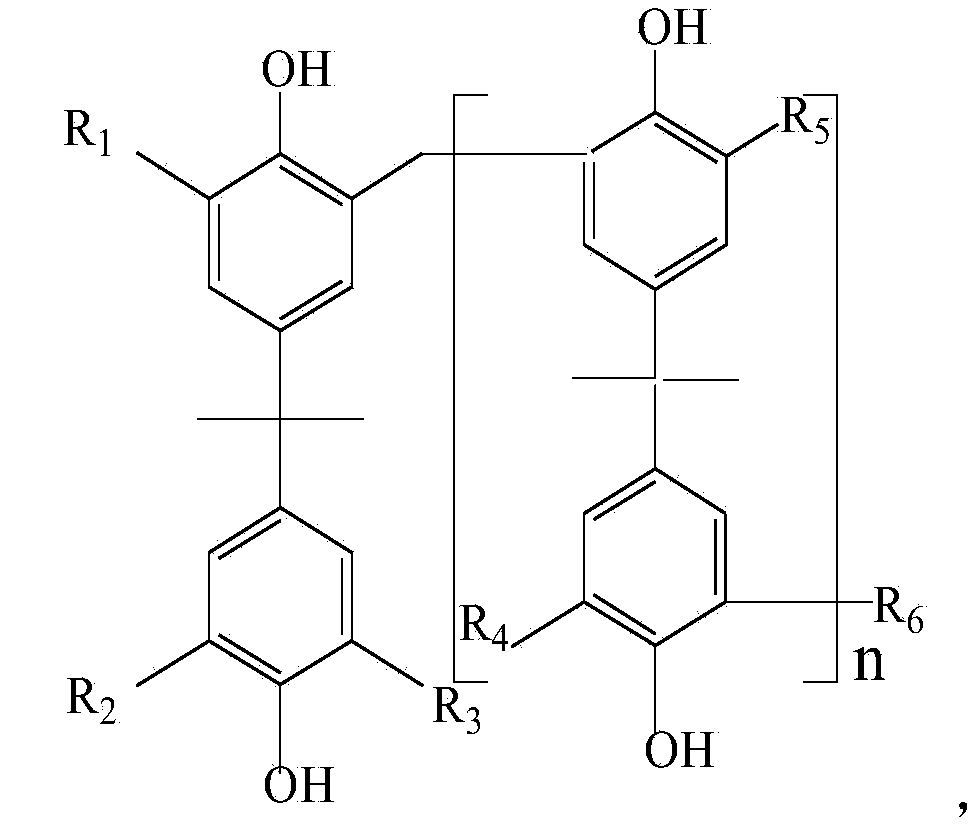

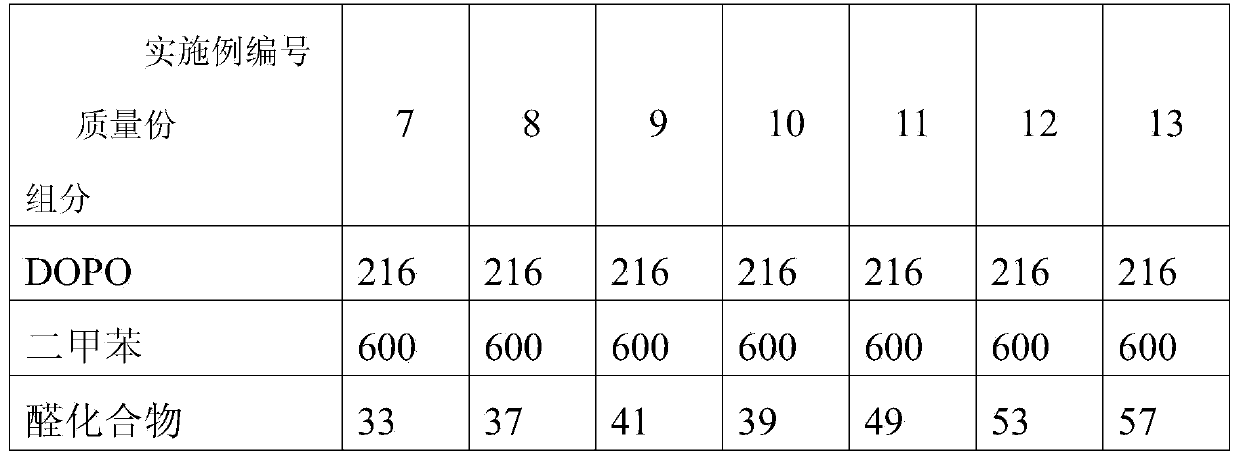

Preparation method of phosphorus-containing bisphenol A phenol formaldehyde resin

The invention discloses a preparation method of a phosphorus-containing bisphenol A phenol formaldehyde resin, which is characterized by comprising the following components: stirring 216 parts by mass of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 600 parts by mass of dimethylbenzene and 30-60 parts by mass of aldehyde compounds at 90-120 DEG C to react to obtain 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide derivatives; and stirring 228 parts of linear bisphenol A phenol formaldehyde resin, 103-738 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide derivatives and 0.23-23 parts of catalyst at 100-220 DEG C to react, cooling, adding n-butanol, mixing, extracting with water, and distilling to remove the n-butanol, thereby obtaining the phosphorus-containing bisphenol A phenol formaldehyde resin. The phosphorus-containing bisphenol A phenol formaldehyde resin prepared by the method is suitable to be used as a reactive flame retardant for epoxy resins and benzoxazine resins, and can also be used as a curing agent for epoxy resins.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Biomass synthetic fuel

InactiveCN101085938AWide range of sourcesPromote environmental protectionLiquid carbonaceous fuelsSolventSide product

The invention discloses a kind of biological synthetic fuel. The comprised component and weight proportion are as follows: monohydric alcohol with 1- 11 carbons 20- 80%, one or many of benzin naphtha, solvent naphtha, dimethyl ether and gasoline 10- 50%, one or many of ether, acetone, butanol and petrohol 4.5- 10%, one or many of hydrogen dioxide, petroleum ether, tertiary-butyl-p-cresol 0.5- 2%, one or many of cyclopentadiene iron, toluene and dimethylbenzene 5- 18%. The main material is industrial waste liquid or side product or agricultural waste, the heat value is high and the dynamic effect is pretty good when used in generator. The invention is characterized by environment- friendly fuel discharge material, wide source of raw material, low production cost and direct utilization of generator. The invention aslo discloses the method for preparing biological synthetic fuel.

Owner:CHONGQING BULAITE BIOMASS ENERGY TECH DEV

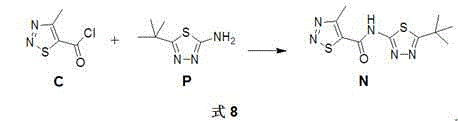

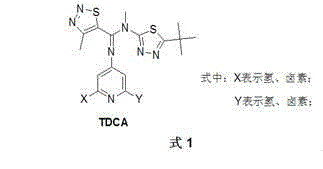

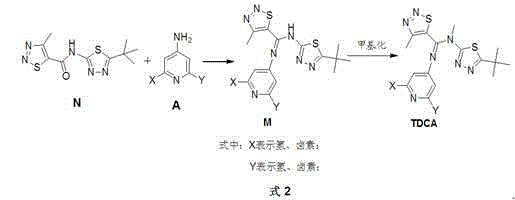

Novel method for synthesizing 1,2,3-thiadiazole-5-formamidine compound

InactiveCN104530040AHigh synthetic yieldSimple ingredientsOrganic chemistryOrganometallic catalysisPtru catalyst

The invention discloses a novel method for synthesizing a 1,2,3-thiadiazole-5-formamidine compound. The target compound shown in general formula TDCA is prepared from a compound as shown in general formula M by virtue of a methylation reaction. The target component as shown in the general formula M is prepared from a compound as shown in general formula A and a compound as shown in general formula N by virtue of a condensation reaction, wherein during the methylation reaction, preferably, a catalyst is an organic metallic catalyst consisting of cuprous iodide and a ligand, namely 2,2,6,6-tetramethyl-3,5-heptadione; during the reaction, preferably, dimethylbenzene is taken as a solvent, and the optimum reaction temperature is 100-140 DEG C. The method disclosed by the invention is high in yield and more environment-friendly (as shown in Specification).

Owner:XIHUA UNIV

In-situ remediation method using peat in underground water polluted by petroleum hydrocarbon as an additive medium

The invention relates to an in-situ remediation method using peat in underground water polluted by petroleum hydrocarbon as an additive medium, which comprises: domesticating a strain; separating the strain; preprocessing peat; performing amplification culture of functional bacteria; immobilizing the functional bacteria receiving the amplification culture in the wet peat which is heated; uniformly mixing the peat carrying the functional bacteria and coarse sand in a certain volume ratio to prepare a reaction wall supporting medium; and filling the reaction wall supporting medium into a permeable reaction wall. The method has the advantages that: the peat used as a biological reaction wall additive medium can effectively immobilize functional bacteria, are insusceptible to flow away with underground water so as to be lost and can effectively absorb petroleum hydrocarbons, benzenes, toluenes, ethylbenzenes, dimethylbenzenes and naphthalines in the underground water, wherein the immobilization rate of the peat is 87 percent according to measurement in experiment and the absorption effect of the peat on polycyclic aromatic hydrocarbons is particularly obvious; nutrients are effectively fed to the functional bacteria in the reaction wall so as to ensure points in the reaction wall can keep high biomass in an operation period; and the peat used is cheap, widely and readily available and ecologically safe.

Owner:JILIN UNIV

Invisible coating material and preparation method thereof

ActiveCN103013256AImprove absorbing performanceLow areal densityCoatingsAcrylic resinCarbon nanotube

The invention discloses an invisible coating material and a preparation method thereof. The invisible coating material comprises a component A and a component B in a weight ratio of (10-15): 1, wherein the component A is prepared from the following raw materials in weight percentage: 40-60% of hydroxyl acrylic resin, 10-15% of carbon nanotube, 5-10% of ceramic powder, 5-8% of vacuum glass microbead, 1-5% of siloxane coupling agent, 1-10% of nano-sized barium sulphate, 1-10% of nano-sized titanium dioxide and 5-10% of dimethylbenzene and butyl acetate mixture; and the component B is prepared from the following raw material in weight percentage: 100% of biuret. The invention provides the invisible coating material with good invisible effect, high wave-absorbing capacity, small surface density, light weight and high bonding strength and the preparation method thereof.

Owner:山东孚日宣威新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com