Method for producing benzene dicarboxylic acid by mixed dimethylbenzene cooxidation

A technology for producing benzenedicarboxylic acid and mixed xylenes, which is applied in chemical instruments and methods, carboxylate preparation, organic compound preparation, etc., can solve the problems of high separation cost and separation difficulty, and achieve the reduction of separation cost, Simplify the process and improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

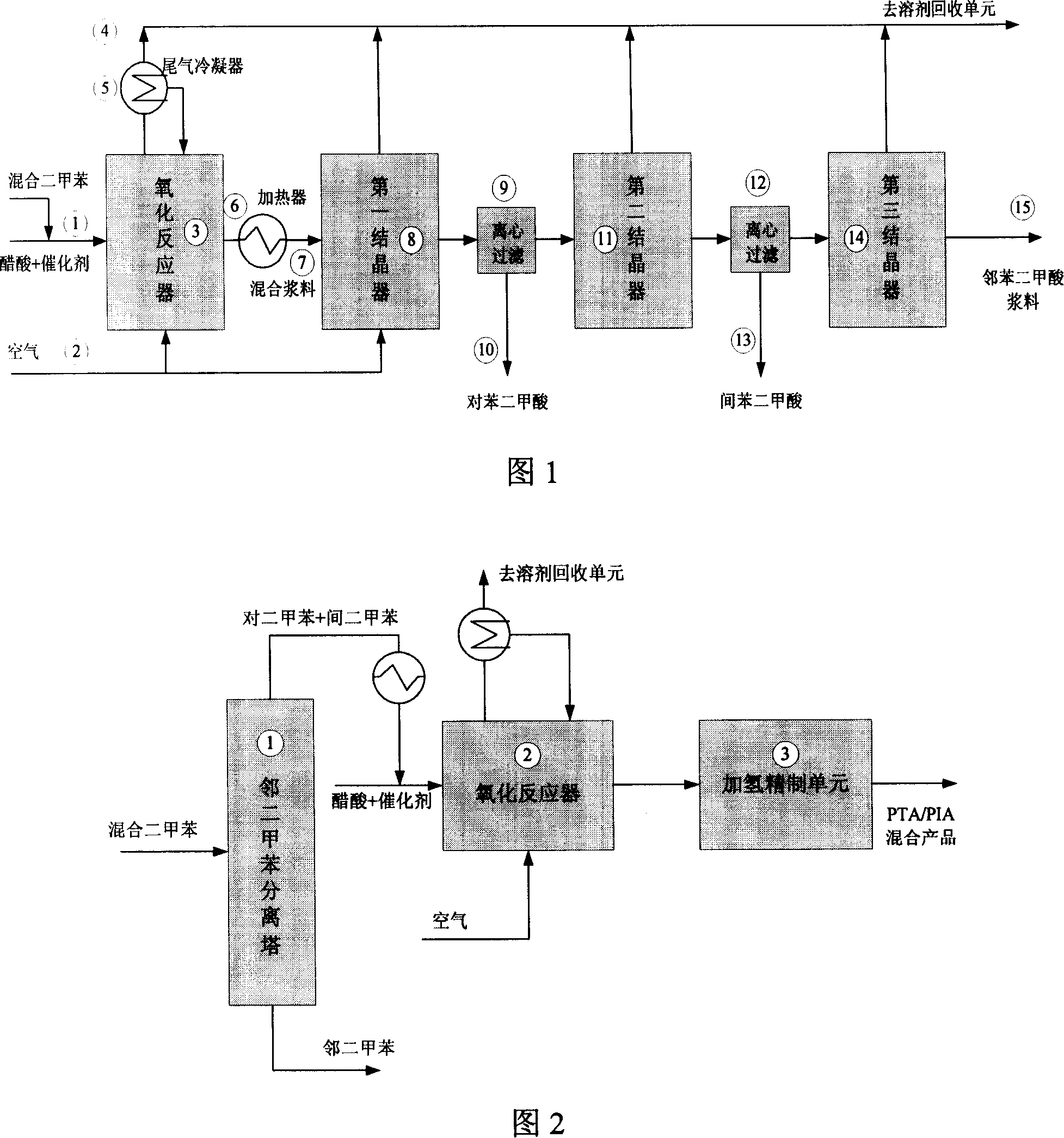

[0030] Figure 1 is a schematic diagram of the process of co-oxidizing mixed xylenes and then obtaining benzenedicarboxylic acid by crystallization and separation. Mixed xylene raw materials containing three isomers, together with solvent acetic acid, catalyst cobalt acetate, manganese acetate and bromide, are fed into oxidation reactor 3 through feeding pipe 1, air or oxygen-containing gas is blown in through inlet pipe 2, and reaction tail gas passes through The tail gas pipe 4 is output, after being condensed by the condenser 5, part of the solvent condensate is refluxed to the reactor 3, and the rest of the tail gas is sent to the subsequent unit for treatment. Obtain the slurry that contains terephthalic acid, isophthalic acid, orthophthalic acid from the slurry outlet pipeline 7 of reactor 3, introduce in the tertiary crystallizer 8,11,14 after being heated up by heater 6, crystallization The temperature and pressure of vessels 8, 11, 14 are reduced step by step so that t...

Embodiment 2

[0045] Fig. 2 is a schematic diagram of a process for co-oxidizing a mixture of p-xylene and m-xylene after separating o-xylene. The mixed xylene raw material first passes through the rectification tower 1, and o-xylene is obtained from the bottom of the tower, and m-xylene and p-xylene are obtained after condensation at the top of the tower; the mixture of m-xylene and p-xylene is introduced into the oxidation reactor 2 together with a solvent and a catalyst, and the reaction slurry The raw material is introduced into the refining unit 3 again, and the product mixture of isophthalic acid and terephthalic acid is obtained after refining.

[0046] In this example, the reaction conditions of the oxidation reactor 2 are the same as in Example 1, the description of the feed and discharge of the reactor is listed in Table 7, and the process conditions of the refining unit 3 are listed in Table 8. What is obtained by this method is a mixture of purified terephthalic acid and purifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com