Method for manufacturing hafnium containing SiC ceramic precursor

A ceramic precursor, C-450 technology, applied in the field of preparation of SiC ceramic precursors, can solve the problems of single function, poor oxidation resistance, poor ultra-high temperature resistance, etc., and achieves wide sources and easy large-scale industrial production. , Excellent effect of ultra-high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

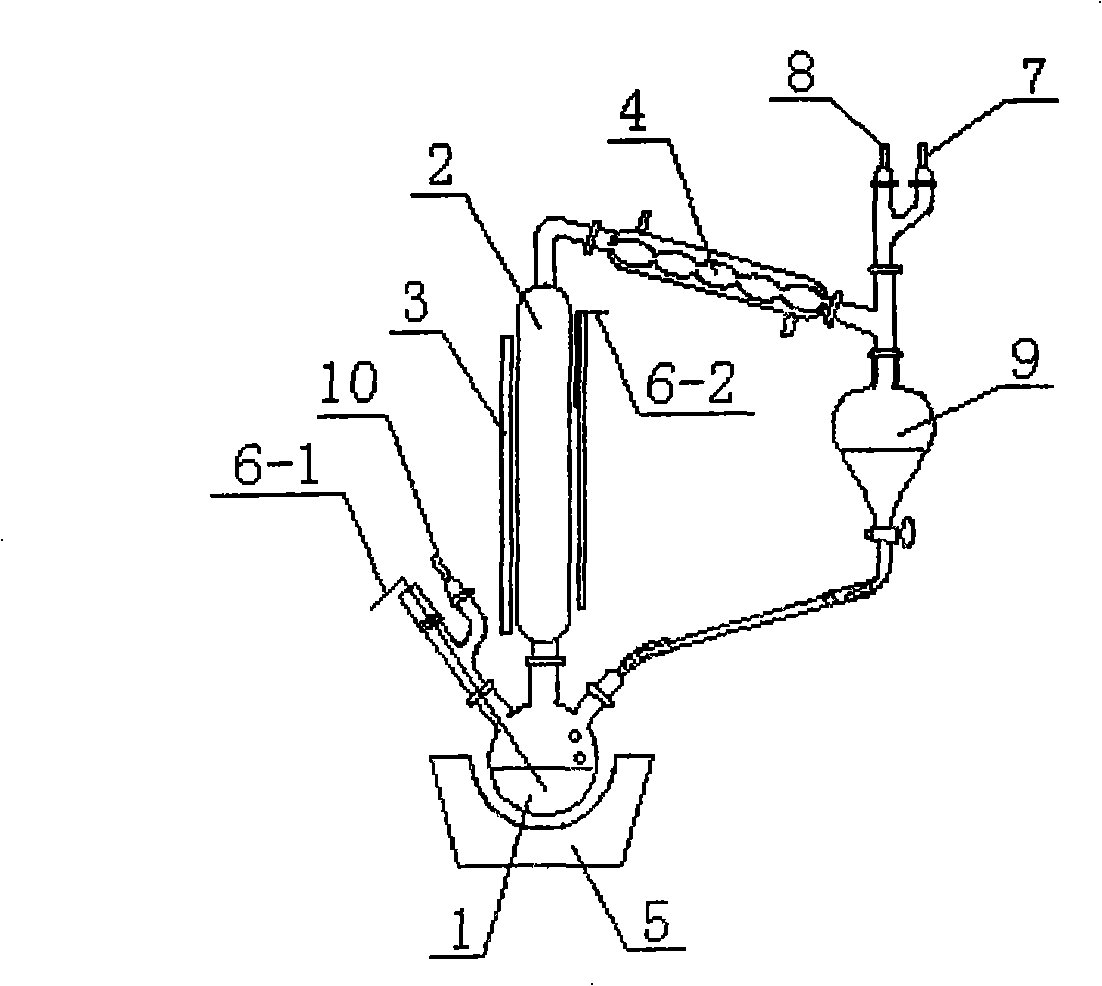

Method used

Image

Examples

Embodiment 1

[0030] Using PSCS and hafnium acetylacetonate as raw materials, the mass ratio of the two (the proportions described below are all mass ratios) is: hafnium acetylacetonate: PSCS=4:100, the reaction temperature is 450 ° C, the cracking temperature is 500 ° C, and the heat preservation reaction After 14 hours, it was dissolved in xylene and filtered, and the filtrate was distilled under reduced pressure at 390° C. to obtain PHCS with a softening point of 200° C. and a hafnium content of 1.91 wt%, with a precursor yield of 64.9%. N 2 Heat preservation at 1200°C for 1 hour under the atmosphere, and the ceramic yield is 79.6%.

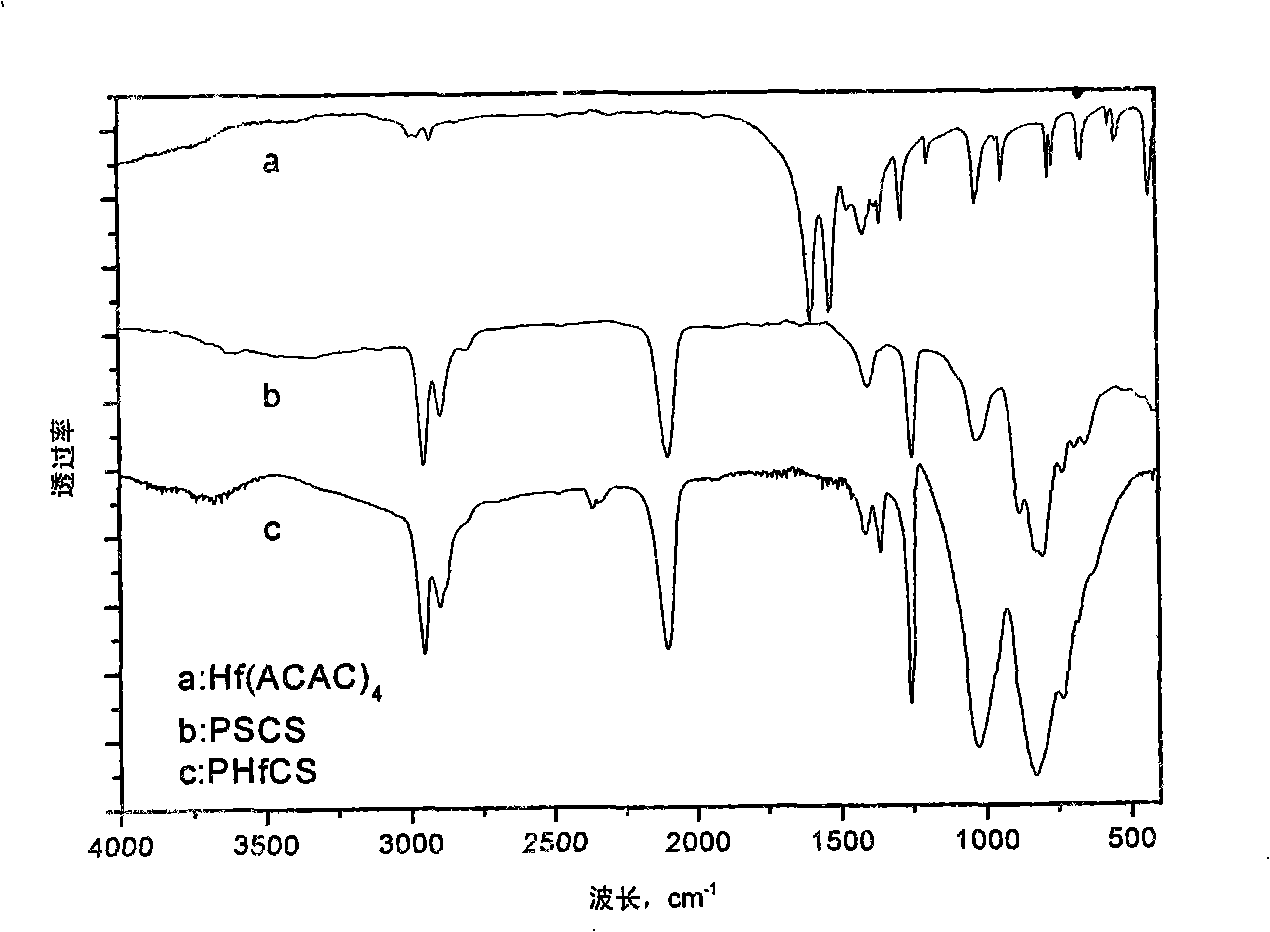

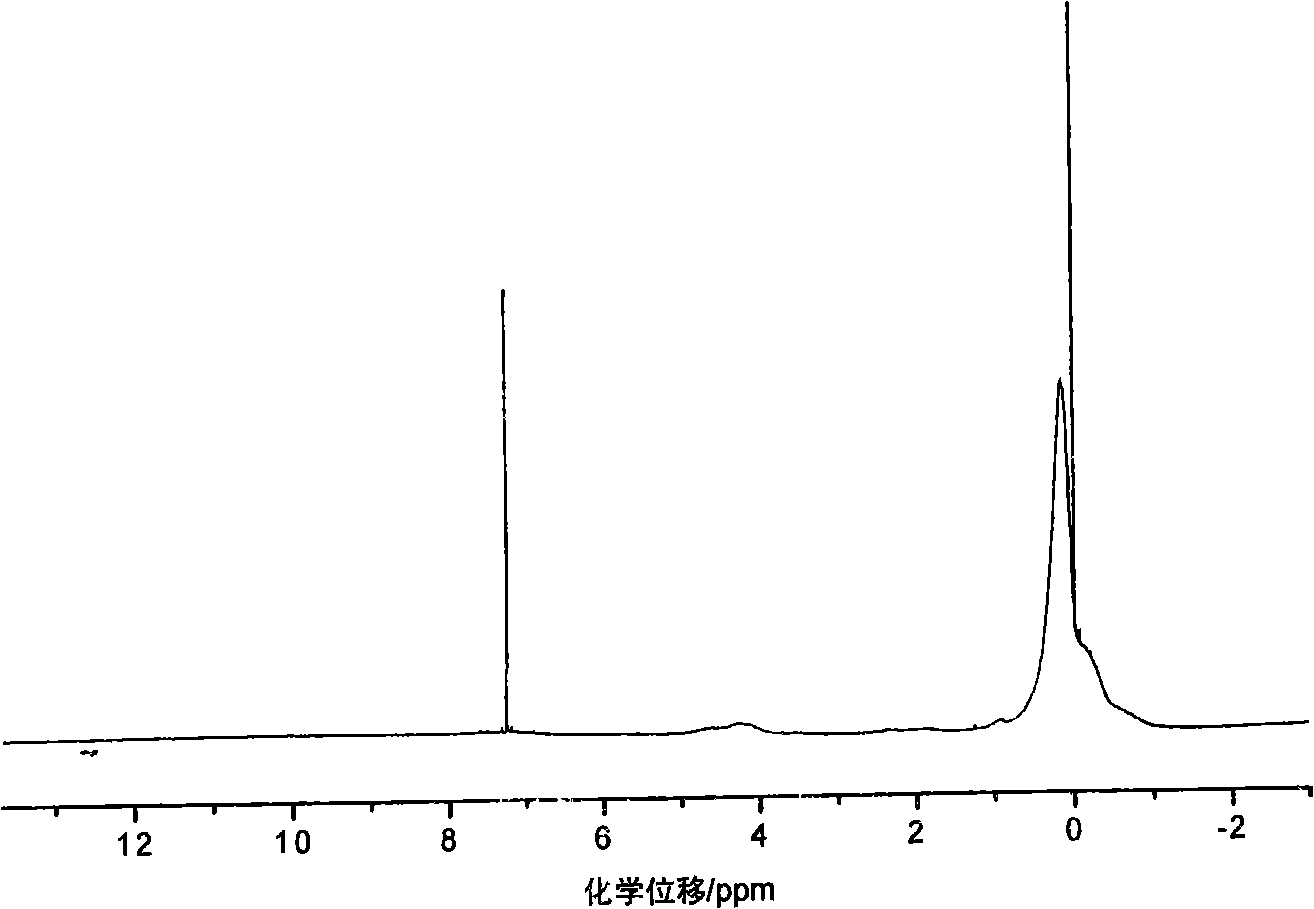

[0031] The infrared spectrogram, GPC spectrogram, TG spectrogram of the obtained PHCS are shown in respectively figure 2 , image 3 , Figure 4 .

[0032] The hafnium-containing SiC ceramic fiber is prepared by using the PHCS precursor through melt-spinning, non-melting in air and firing at high temperature. The fiber diameter is 14μm, and the tensile...

Embodiment 2

[0034] Using PCS and tetraethoxyhafnium as raw materials, tetraethoxyhafnium:PCS=1:100, the reaction temperature is 460°C, the cracking temperature is 450°C, and after the reaction time of 4h, it is dissolved in xylene and filtered, and the filtrate is dissolved at 300°C °C for vacuum distillation to prepare PHCS with a softening point of 210 °C and a hafnium content of 0.63 wt%, with a precursor yield of 71.2%. N 2 The temperature was kept at 1200° C. for 1 hour under the atmosphere, and the ceramic yield was 76.2%.

[0035] The hafnium-containing SiC ceramic fiber is prepared by using the PHCS precursor through melt-spinning, non-melting in air and firing at high temperature. The fiber diameter is 16μm, and the tensile strength is 1.7GPa. The fiber has good ultra-high temperature resistance. After treatment at 1450°C and 1600°C, the strength retention rate is 65% and 37% respectively; the Si-Hf-C-O fiber has good oxidation resistance. After heat treatment at 1000°C for 20 ...

Embodiment 3

[0037] Using PSCS and hafnium tetrachloride as raw materials, the mass ratio of the two is: hafnium tetrachloride:PSCS=15:100, the reaction temperature is 420°C, the cracking temperature is 500°C, after the heat preservation reaction for 3 hours, it is dissolved in xylene and filtered. The filtrate was distilled under reduced pressure at 350° C. to obtain PHCS with a softening point of 165° C. and a hafnium content of 7.75 wt%, with a precursor yield of 56.2%. N 2 Heat preservation at 1200°C for 1 hour under the atmosphere, and the ceramic yield is 69.7%.

[0038] The hafnium-containing SiC ceramic fiber is prepared by using the PHCS precursor through melt-spinning, non-melting in air and firing at high temperature. The fiber diameter is 15μm, and the tensile strength is 2.1GPa. The fiber has good ultra-high temperature resistance. After treatment at 1450°C and 1600°C, the strength retention rate is 68% and 40% respectively; the Si-Hf-C-O fiber has good oxidation resistance....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com