Method for high selectively synthesizing dimethylbenzene through benzene and methanol alkylation reaction

An alkylation reaction, high selectivity technology, applied in organic chemistry, bulk chemical production, condensation between hydrocarbons and non-hydrocarbons, etc., can solve the low selectivity of xylene, no improvement in conversion rate, stability Deletion and other problems can be achieved to enhance reaction stability and inhibit reaction coking and inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

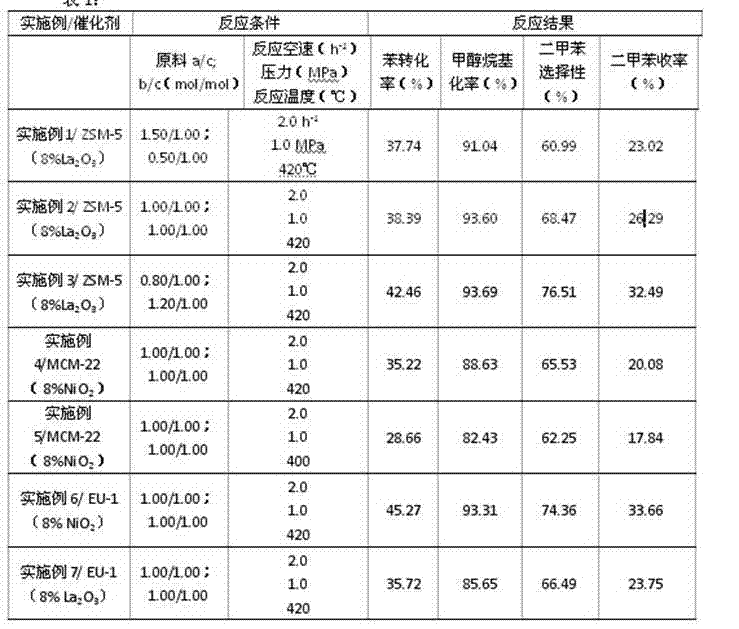

Embodiment 1

[0023] Example 1: Put an appropriate amount of glass beads at both ends of the stainless steel fixed bed reaction tube of 1.5cm in the inner diameter, and a 4.00g cylindrical catalyst ZSM-5 (8%LA (8%LA (8%LA 2 O 3 ) (Si / Al = 24), and then connect with hydrogen gas, H 2 The Moore of the hydrocarbon is 2.0: 1 to ensure that the airflow is uniformly flowing over the catalyst bed layer; the reaction pressure is 1.0MPa, and it is heated to the reaction set temperature of 420 ° C by 100MINS.) = 1.50 / 1.00 (mol / mol), B (toluene) / C (methanol) = 0.50 / 1.00 (mol / mol), the quality of the quality is 2.0H -1 , Examine the catalytic effect, analyze the chromatography of the sample, calculate the one -way conversion rate of the benzene after the reaction, the methanol alkyrization rate, the selectability of dyshane, and the second tailoris.

Embodiment 2

[0024] Example 2: The difference between this embodiment and Example 1 is that the raw material group becomes A (benzene) / C (methan) = 1.00 / 1.00 (mol / mol), B (methane) / C (methanol) = 1.00 / 1.00(Mol / mol); reactive gas is CO 2 , And CO 2 The Moorby with hydrocarbons is 1.0: 1; other conditions are shown in Table 1.

Embodiment 3

[0025] Example 3: The difference between this embodiment and Example 1 is that the raw material group becomes A (benzene) / C (methan) = 0.80 / 1.00 (mol / mol), B (methane) / C (methanol) = 1.20 / 1.00(Mol / mol); 2 , And n 2 The Moorby with raw materials is 3.0: 1; other conditions are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com