Synthetic method of acrylic resin

A technology of acrylic resin and synthesis method, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion, and achieve the effect of improving adhesion, good physical and chemical properties and construction properties, and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

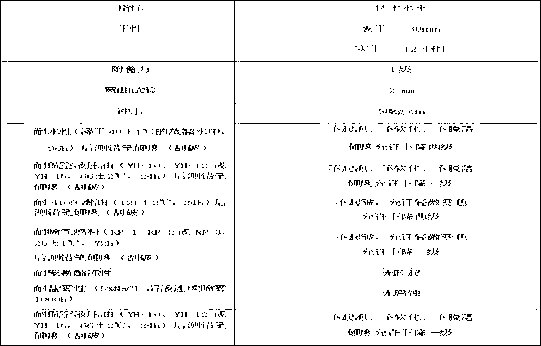

[0017] The synthetic method of described acrylic resin comprises the following steps:

[0018] Step 1) Pour 2 / 3 parts by weight of the above xylene, 10-15 parts of toluene, and 8-10 parts of butyl acetate into the reactor to form a solvent, and leave 1 / 3 of the xylene to flush the pipeline;

[0019] Step 2) Dissolve 0.3-0.8 parts of initiator 1 with 15-19 parts of methyl methacrylate, and then add the above weight parts of styrene, butyl acrylate, acrylic acid and 1 / 3 of the above formula amount of hydroxypropyl acrylate and The mixed solvent in step 1) is mixed into a mixed monomer and put into the head tank;

[0020] Step 3) Turn on the condenser, raise the temperature, keep reflux, start dropwise adding the mixed monomer in step 2) at 120-125°C, control the addition in 2.5-3 hours, when the mixed monomer is dropped halfway, add another 1 / 3 The hydroxypropyl acrylate of the above-mentioned formula amount is added to this mixed monomer. After adding, the mixed solution was...

Embodiment 1

[0023] Get 17kg of methyl methacrylate, 8kg of styrene, 22kg of butyl acrylate, 7kg of hydroxypropyl acrylate, 1.2kg of acrylic acid, 0.5kg of initiator 1, 0.3kg of initiator 2, and 0.3kg of initiator The xylene of agent 3,17.7kg, the toluene of 12kg, the butyl acetate of 9kg; Described initiator 1, initiator 2, initiator 3 are benzoyl peroxide.

[0024] The synthetic method of described acrylic resin comprises the following steps:

[0025] Step 1) Pour 11.8kg of xylene, 12kg of toluene, and 9kg of butyl acetate into the reactor to form a solvent, and set aside 5.9kg of xylene to flush the pipeline;

[0026] Step 2) Dissolve 0.5kg of initiator 1 with 17kg of methyl methacrylate, then add 8kg of styrene, 22kg of butyl acrylate, 1.2kg of acrylic acid and 1 / 3 of the above formula amount of hydroxypropyl acrylate and step 1) The mixed solvent is mixed into a mixed monomer, which is poured into the high level tank;

[0027] Step 3) Turn on the condenser, raise the temperature, ke...

Embodiment 2

[0030] Get 15kg of methyl methacrylate, 5kg of styrene, 20kg of butyl acrylate, 6kg of hydroxypropyl acrylate, 1.0kg of acrylic acid, 0.3kg of initiator 1, 0.1kg of initiator 2, and 0.1kg of initiator The xylene of agent 3,17.7kg, the toluene of 10kg, the butyl acetate of 8kg; The synthetic method of described acrylic resin is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com