Method for dimethylbenzene and trimethylbenzene by alkylating benzene and methanol

A technology of xylene and trimethylbenzene, which is applied in the field of organic chemical synthesis, can solve the problems that trimethylbenzene technology has not been reported, and achieve the effect of uncomplicated equipment and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

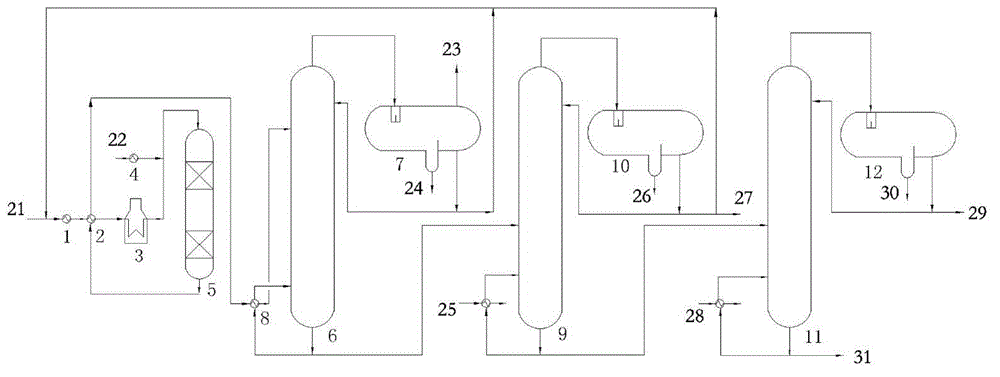

[0050] The preparation method of the present invention comprises the steps:

[0051] 1. The fresh raw material benzene is mixed with circulating benzene, toluene and xylene, and then enters the feed heating furnace (3) to be heated to the reaction temperature after passing through the gasifier (1) and the heat exchanger (2), and then is heated to the reaction temperature with the gasifier ( 4) The methanol that comes out is sent into the alkylation reactor (5) together for reaction. The alkylation reactor is filled with a modified ZSM-5 zeolite molecular sieve catalyst, and the reaction product enters the toluene removal tower (6) after heat exchange by a heat exchanger (2) and a bottom reboiler (8) of the removal toluene tower.

[0052] 2. After the alkylation reaction product enters the toluene removal tower (6), the vapor phase at the top of the tower is condensed by a total condenser and enters the toluene removal tower reflux tank (7). In the reflux tank (7), the unconden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com