Hydrophobic and oleophyllic bi-component acrylic resin and preparation method and application thereof

An acrylic resin and lipophilic technology, which is applied in the field of hydrophobic and lipophilic two-component acrylic resin and its preparation, and can solve the problems of hydrophobic and lipophilic surfaces that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

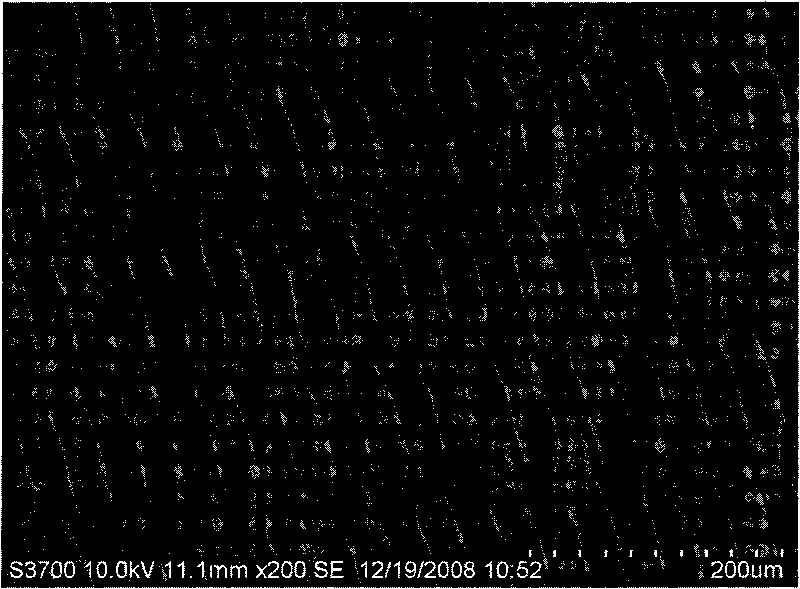

Image

Examples

Embodiment 1

[0026] The method for preparing a hydrophobic and lipophilic coating by using a hydrophobic and lipophilic two-component acrylic resin comprises the following steps:

[0027] The preparation method of component A is: by weight percentage, 10% of isobornyl methacrylate, 20% of hexadecyl methacrylate, 10% of hexafluorobutyl acrylate, 10% of hydroxymethacrylate After mixing ethyl ester and 2% azobisisobutyronitrile, slowly drop them into the preheated reflux mixed solvent of butyl acetate and xylene, the content of butyl acetate is 23%, and the content of xylene is 25%. Fully stir the reaction, the reaction temperature is 85°C, and the reaction time is 8h.

[0028] Component B is HDI biuret, in which the NCO content accounts for 23% of the total weight of the curing agent. In terms of parts by weight, take 100 parts of component A and 15 parts of component B, stir evenly, dilute the mixture with butyl acetate and xylene to a concentration of 2% by weight, and then impregnate the...

Embodiment 2

[0032] The method for preparing a hydrophobic and lipophilic coating by using a hydrophobic and lipophilic two-component acrylic resin comprises the following steps:

[0033] The preparation method of component A is: by weight percentage, 15% methyl methacrylate, 25% lauryl methacrylate, 8% dodecafluoroheptyl methacrylate, 15% methacrylic acid After the hydroxypropyl ester and 1% benzoyl peroxide are mixed, slowly drop them into the preheated reflux butyl acetate and xylene mixed solvent, the content of butyl acetate is 10%, and the content of xylene is 26%. Fully stir the reaction, the reaction temperature is 130°C, and the reaction time is 6h.

[0034]Component B is HDI trimer, wherein the NCO content accounts for 22% of the total weight of the curing agent. In terms of parts by weight, take 100 parts of component A and 22 parts of component B, stir evenly and dilute the mixture with butyl acetate and xylene to a concentration of 3% by weight, then soak the mixture with 380...

Embodiment 3

[0036] The method for preparing a hydrophobic and lipophilic coating by using a hydrophobic and lipophilic two-component acrylic resin comprises the following steps:

[0037] The preparation method of component A is: by weight percentage, 12% styrene, 15% stearyl methacrylate, 5% dodecafluoroheptyl acrylate, 8% hydroxyethyl acrylate, 3% After azobisisobutyronitrile is mixed, it is slowly added dropwise into the preheated reflux mixed solvent of butyl acetate and xylene, the content of butyl acetate is 25%, and the content of xylene is 32%. Fully stir the reaction, the reaction temperature is 80°C, and the reaction time is 9h.

[0038] Component B is IPDI trimer, wherein the NCO content accounts for 12% of the total weight of the curing agent. In terms of parts by weight, take 100 parts of component A and 27 parts of component B, stir evenly, dilute the mixture with butyl acetate and xylene to a concentration of 4% by weight, and then impregnate the 200-mesh stainless steel pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com