Preparation method of phosphorus-containing bisphenol A phenol formaldehyde resin

A technology of phenolic resin and phosphorus bisphenol, which is applied in the field of preparation of organic polymer compounds, can solve problems affecting health and the environment, severe toxicity, etc., and achieve the effects of good product performance, simple preparation process, and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

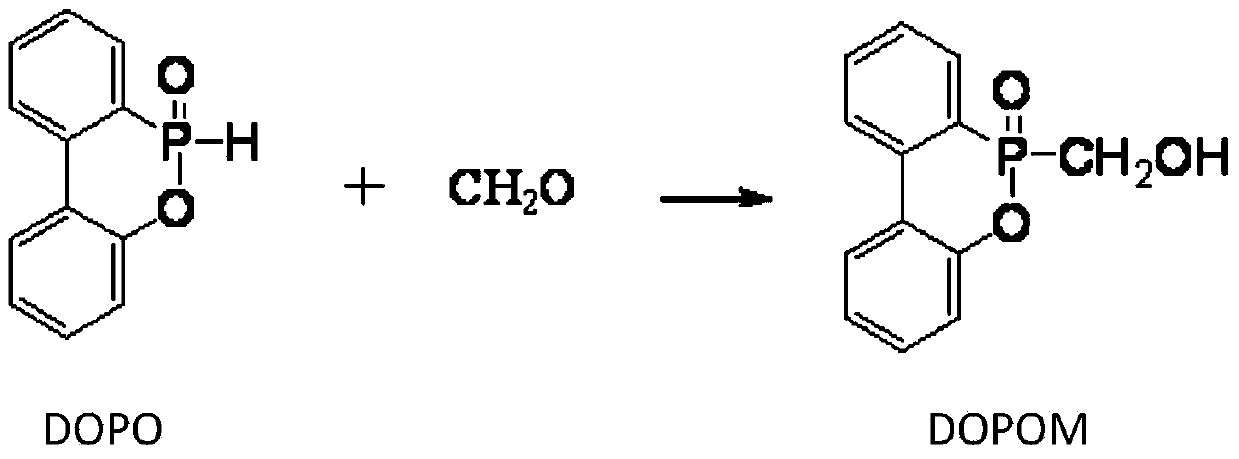

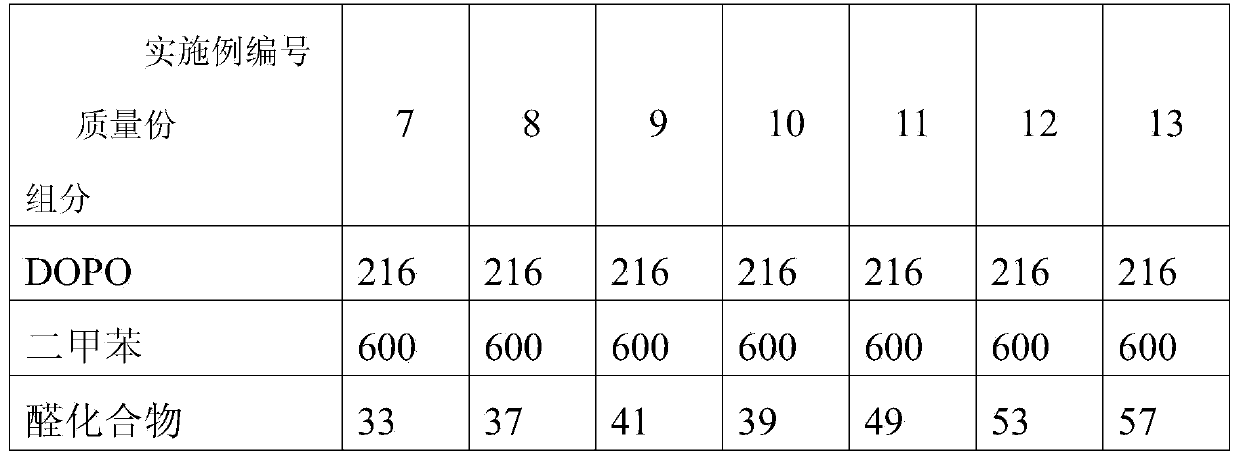

[0037] In a reactor A equipped with a reflux condenser, stirring, and thermocouple, add 216kg DOPO and 600kg xylene, heat up to 90°C, then add 32.6kg paraformaldehyde under stirring, and then react under stirring for 6 hours. The product DOPOM was precipitated and filtered after cooling and precipitation. Then add an appropriate amount of mixed solvent of xylene and ethanol (volume ratio 1:1) to recrystallize 3 times. Obtain DOPOM finished product 226.3kg after drying, productive rate 92%.

Embodiment 1-2

[0039]In a reactor A equipped with a reflux condenser, stirring, and thermocouple, add 216kg DOPO and 600kg xylene, heat up to 110°C, then add 34.3kg paraformaldehyde under stirring, and then react for 4 hours under stirring, The product DOPOM was precipitated and filtered after cooling and precipitation. Then recrystallize three times with a mixed solvent of xylene and ethanol (volume ratio 1:1). Obtain DOPOM finished product 236kg after drying, productive rate 96%.

Embodiment 1-3

[0041] In a reactor A equipped with a reflux condenser, stirring, and thermocouple, add 216kg DOPO and 600kg xylene, raise the temperature to 120°C, then add 39kg paraformaldehyde under stirring, and react for 2 hours under stirring, the product DOPOM was precipitated, filtered after cooling and precipitated. Recrystallize three times with a mixed solvent of xylene and ethanol (volume ratio 1:1). After drying, 239 kg of DOPOM product is obtained, with a yield of 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com