High-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and preparation method thereof

A polyurethane adhesive and phenolic resin technology, applied in the field of polymers, can solve the problems of low cohesive strength and poor high temperature resistance of polyurethane adhesives, and achieve improved bond strength, high temperature resistance, high temperature resistance, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing a high-bond strength and high-temperature-resistant phenolic resin-modified polyurethane adhesive, comprising the following steps:

[0023] Synthesis of modified phenolic resin: 9-11 parts by weight of methoxyxylene monomer and 9-10 parts by weight of phenols are added at 115-135 ° C, and 0.1-0.3 parts by weight of acidic catalyst are added to react for 2-3 hours , after dehydration, lower the temperature and cool down, then add 0.3-0.6 parts by weight of basic catalyst, 6-10 parts by weight of organic solvent and 9-11 parts by weight of formaldehyde, dehydration reaction under vacuum of 0.3-0.75KPa, until transparent Obtain modified phenolic resin;

[0024] Preparation of polyurethane prepolymer: react 10-30 parts by weight of polyisocyanate and 40-100 parts by weight of polyester polyol at 65-75°C for 2-3 hours to obtain a polyurethane prepolymer;

[0025] Synthesis of modified polyurethane prepolymer: react the modified ...

Embodiment 1

[0038] Add 9 parts of methoxyxylene monomer, 9 parts of phenol and 0.1 part of sulfuric acid with a concentration of 20wt%, and react for 3 hours at 115°C. After cooling down, add 0.3 parts of potassium hydroxide, 6 parts of toluene and 9 parts of Formaldehyde, dehydration reaction under a vacuum of 0.3KPa, to obtain a modified phenolic resin after being transparent;

[0039] 10 parts of toluene diisocyanate and 40 parts of polyethylene adipate with a relative molecular weight of 2000 were reacted at 65°C for 2 hours to obtain a polyurethane prepolymer;

[0040] React the modified phenolic resin with the polyurethane prepolymer at 65°C for 2.5 hours to obtain a modified polyurethane prepolymer;

[0041]Add water to the modified polyurethane prepolymer and disperse it with a disperser. The speed of the disperser is 1500r / min. React at ℃ for 15 minutes to obtain a modified water-based polyurethane adhesive.

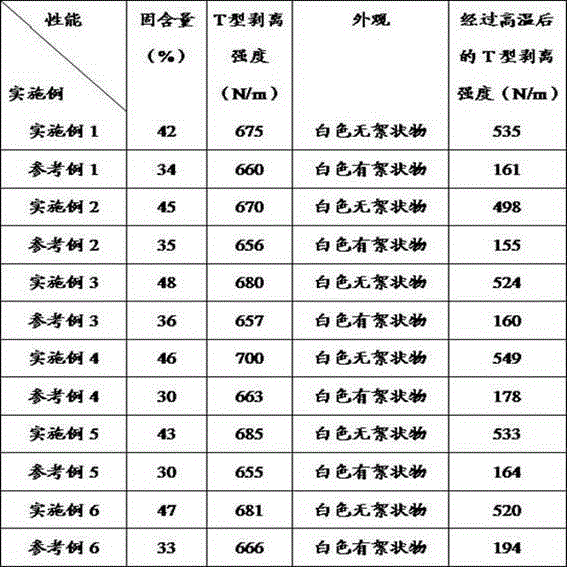

[0042] The test of the modified polyurethane adhesive prepared by th...

Embodiment 2

[0044] Add 10 parts of methoxyxylene monomer, 10 parts of phenol and 0.2 parts of hydrochloric acid with a concentration of 25wt%, and react for 3 hours at 125°C. After cooling down, add 0.5 parts of sodium hydroxide, 8 parts of toluene and 10 parts of Formaldehyde, dehydration reaction under the vacuum of 0.5KPa, obtain modified phenolic resin after becoming transparent;

[0045] 20 parts of diphenylmethane-4,4'-diisocyanate and 60 parts of polycaprolactone diol with a relative molecular weight of 3000 were reacted at 75°C for 3 hours to obtain a polyurethane prepolymer;

[0046] React the modified phenolic resin with the polyurethane prepolymer at 75°C for 2.5 hours to obtain a modified polyurethane prepolymer;

[0047] Add water to the modified polyurethane prepolymer, disperse it with a disperser, the speed of the disperser is 2500r / min, add 1.0 parts of methylamine, 0.5 parts of butanediamine and 2 parts of neopentyl glycol, and react at 45°C for 10 minutes , to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| T-peel strength | aaaaa | aaaaa |

| T-peel strength | aaaaa | aaaaa |

| T-peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com