Aluminum film water system photoresistance stripping liquid in liquid crystal panel manufacture technology and preparation method thereof

A manufacturing process and technology for liquid crystal panels, applied in the field of aluminum film water-based photoresist stripping solution and its preparation, can solve problems such as large environmental pollution and human health damage, and achieve the effects of avoiding damage, reducing temperature, and improving photoresist stripping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

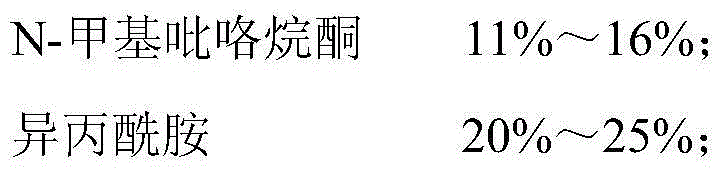

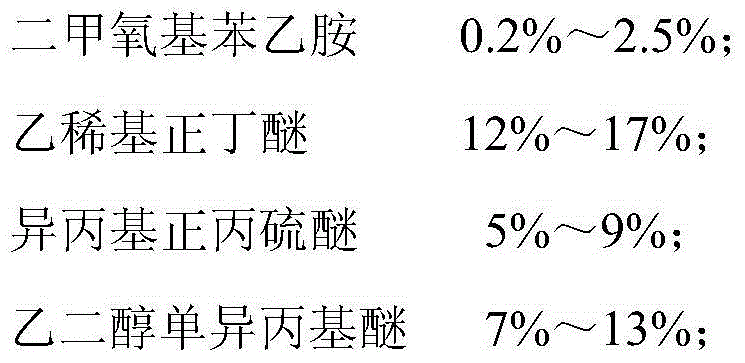

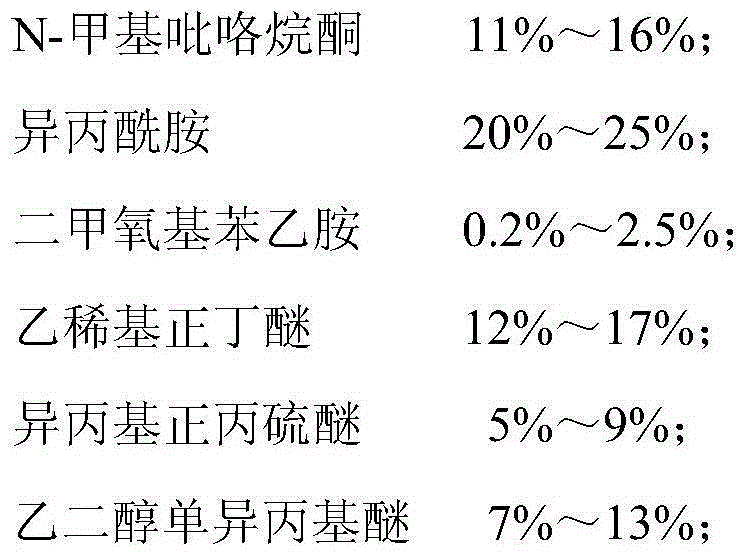

[0024] Embodiment 1. Weigh 11 kg of N-methylpyrrolidone, add it into a reaction kettle equipped with 5 kg of water through an automatic feeder under stirring, and fully stir at normal temperature and pressure. The stirring time is: 15 minutes. The speed is 65 rpm; 20kg of isopropanamide, 0.2kg of dimethoxyphenethylamine, 12kg of vinyl n-butyl ether, 5kg of isopropyl n-propyl sulfide, and ethylene glycol monoisopropyl ether 7kg, then add water to 100kg, stir again for 15 minutes, the stirring speed is 70 rpm; start the diaphragm pump, and circulate the prepared mixture through a 0.3um filter for 2 hours, and then filter through a 0.15μm filter , to remove harmful particles with a particle size greater than 0.15 μm in the mixture, that is, to prepare an aluminum film water-based photoresist stripping solution.

Embodiment 2

[0025] Example 2, weigh 12 kg of N-methylpyrrolidone, add it into a reaction kettle equipped with 8 kg of water through an automatic feeder under stirring, fully stir at normal temperature and pressure, and the stirring time is: 18 minutes, stirring The speed is 65 rpm; add 21kg of isopropanamide, 0.5kg of dimethoxyphenethylamine, 13kg of vinyl n-butyl ether, 6kg of isopropyl n-propyl sulfide, and ethylene glycol monoisopropyl ether 8kg, then add water to 100kg, stir again for 18 minutes, the stirring speed is 70 rpm; start the diaphragm pump, and circulate the obtained mixture through a 0.3um filter for 2 hours, and then filter through a 0.15μm filter , to remove harmful particles with a particle size greater than 0.15 μm in the mixture, that is, to prepare an aluminum film water-based photoresist stripping solution.

Embodiment 3

[0026] Example 3, weigh 13kg of N-methylpyrrolidone, add it into a reaction kettle equipped with 10kg of water through an automatic feeder under stirring, fully stir at normal temperature and pressure, the stirring time is: 20 minutes, stirring The speed is 70 rpm; 22kg of isopropanamide, 0.8kg of dimethoxyphenethylamine, 14kg of vinyl n-butyl ether, 7kg of isopropyl n-propyl sulfide, and ethylene glycol monoisopropyl ether are added at a time. 10kg, then add water to 100kg, stir again for 20 minutes, the stirring speed is 75 rpm; start the diaphragm pump, and circulate the prepared mixture through a 0.3um filter for 3 hours, and then filter through a 0.15μm filter , to remove harmful particles with a particle size greater than 0.15 μm in the mixture, that is, to prepare an aluminum film water-based photoresist stripping solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com