Lubricating agent used for titanium magnesium alloy drawing process and preparation method thereof

A technology of titanium-magnesium alloys and lubricants, which is applied in the direction of lubricating compositions and the petroleum industry, can solve the problems of physical hazards to workers, easy scratches and rusts on the surface of workpieces, and surface scratches, etc., so as to increase the added value of production and production Efficiency, eliminate dust hazards in the workshop, prevent scratches and rust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

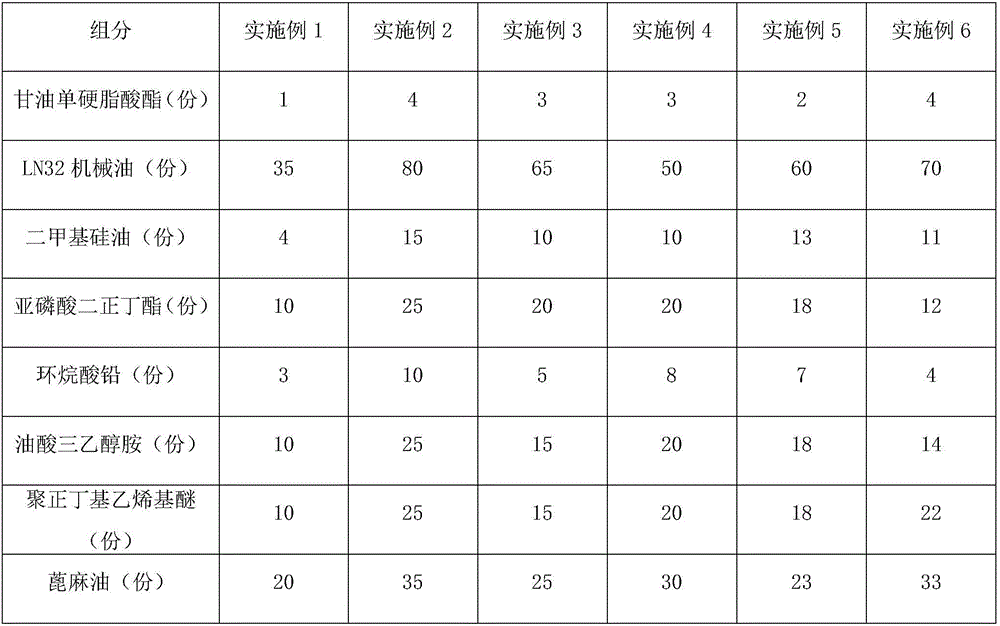

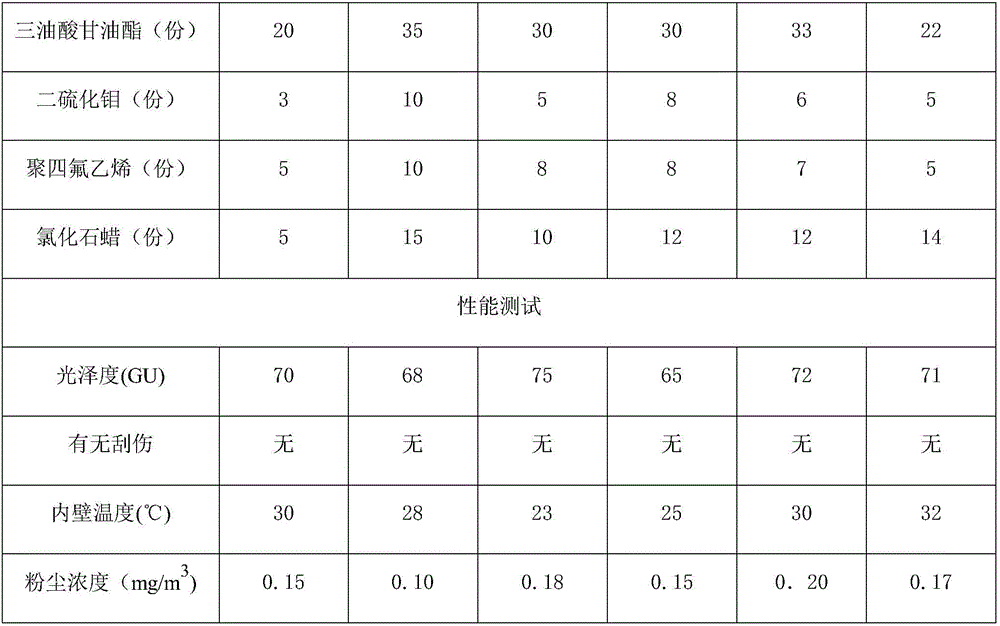

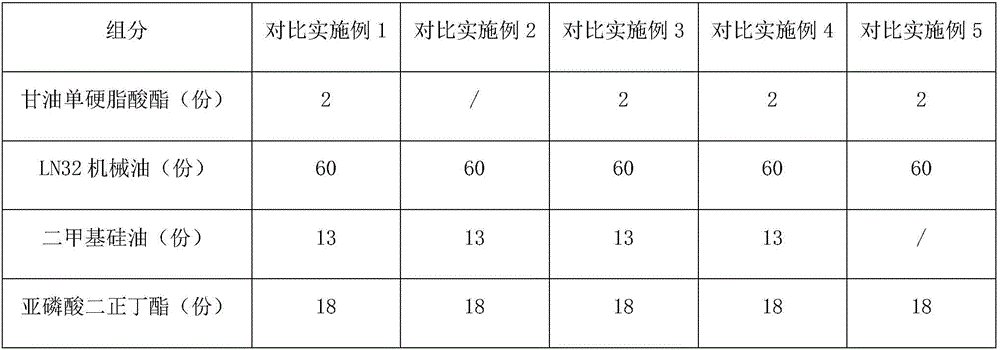

Embodiment 1

[0025] A preparation method for a lubricant for a titanium-magnesium alloy drawing process, comprising the steps of:

[0026] (1) 1 part of glycerol monostearate, 3 parts of lead naphthenate, 10 parts of triethanolamine oleate, 10 parts of poly-n-butyl vinyl ether, 3 parts of molybdenum disulfide, 5 parts of polytetrafluoroethylene and Put 5 parts of chlorinated paraffin into the mixing station, fully mix to make basic powder;

[0027] (2) Add 35 parts of LN32 mechanical oil, 4 parts of simethicone oil, 10 parts of di-n-butyl phosphite, 20 parts of castor oil, and 20 parts of glyceryl trioleate into the liquid mixing station, fully stir and mix to form a viscous Thick liquid additives;

[0028] (3) Add the mixed basic powder into the tower spray granulator, and spray the liquid additive onto the basic powder through the tower spray granulator, granulate, polish and shape, and obtain finished granules.

Embodiment 2

[0030] A preparation method for a lubricant for a titanium-magnesium alloy drawing process, comprising the steps of:

[0031] (1) 4 parts of glycerol monostearate, 10 parts of lead naphthenate, 25 parts of triethanolamine oleate, 25 parts of poly-n-butyl vinyl ether, 10 parts of molybdenum disulfide, 10 parts of polytetrafluoroethylene and Put 15 parts of chlorinated paraffin into the mixing station, fully mix to make basic powder;

[0032] (2) Add 80 parts of LN32 mechanical oil, 15 parts of simethicone oil, 25 parts of di-n-butyl phosphite, 35 parts of castor oil, and 35 parts of glyceryl trioleate into the liquid mixing station, fully stir and mix to form a viscous Thick liquid additives;

[0033] (3) Add the mixed basic powder into the tower spray granulator, and spray the liquid additive onto the basic powder through the tower spray granulator, granulate, polish and shape, and obtain finished granules.

Embodiment 3

[0035] A preparation method for a lubricant for a titanium-magnesium alloy drawing process, comprising the steps of:

[0036](1) 3 parts of glycerol monostearate, 5 parts of lead naphthenate, 15 parts of triethanolamine oleate, 15 parts of poly-n-butyl vinyl ether, 5 parts of molybdenum disulfide, 8 parts of polytetrafluoroethylene and Put 10 parts of chlorinated paraffin into the mixing station, fully mix to make basic powder;

[0037] (2) Add 65 parts of LN32 mechanical oil, 10 parts of simethicone oil, 20 parts of di-n-butyl phosphite, 25 parts of castor oil, and 30 parts of glyceryl trioleate into the liquid mixing station, fully stir and mix to form a viscous Thick liquid additives;

[0038] (3) Add the mixed basic powder into the tower spray granulator, and spray the liquid additive onto the basic powder through the tower spray granulator, granulate, polish and shape, and obtain finished granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com