Method for preparing biological organic fertilizer by using fermentation tank

A technology of bio-organic fertilizer and bio-organic fertilizer, which is applied in the preparation, application and application of organic fertilizers, can solve the problems of mosquitoes and flies affecting the surrounding environment, difficult to control fermentation conditions, long production cycle, etc., and achieves good product quality, The effect of fast fertilizer production and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

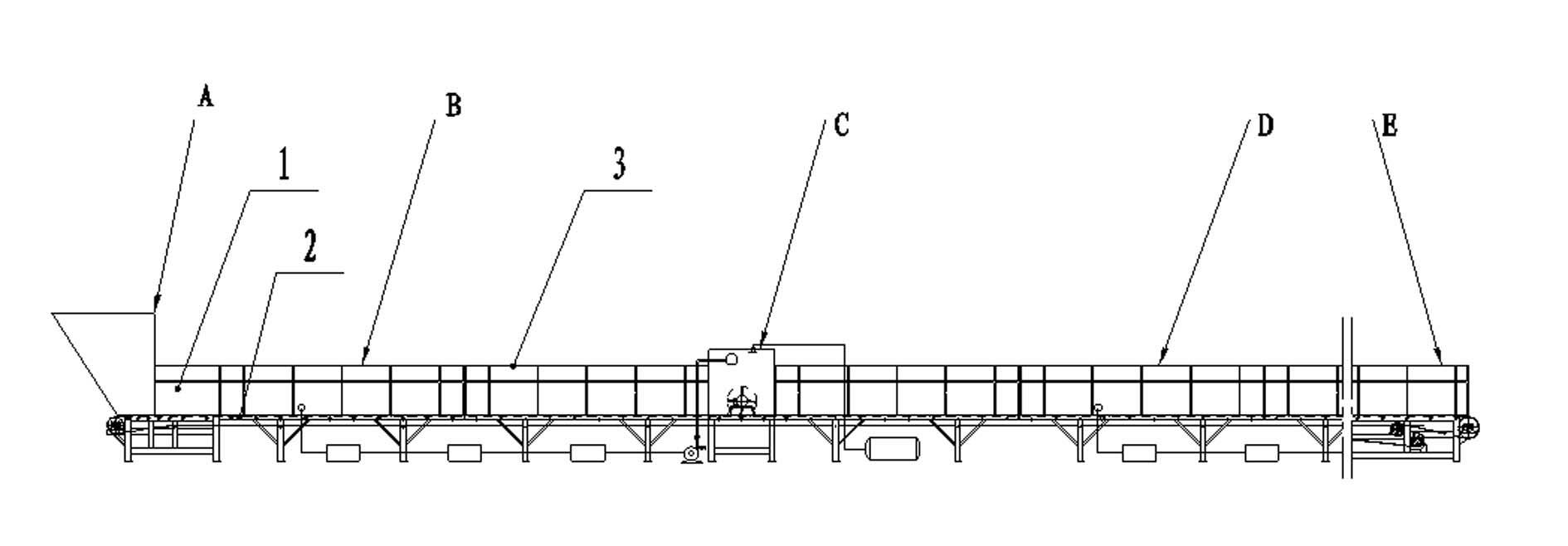

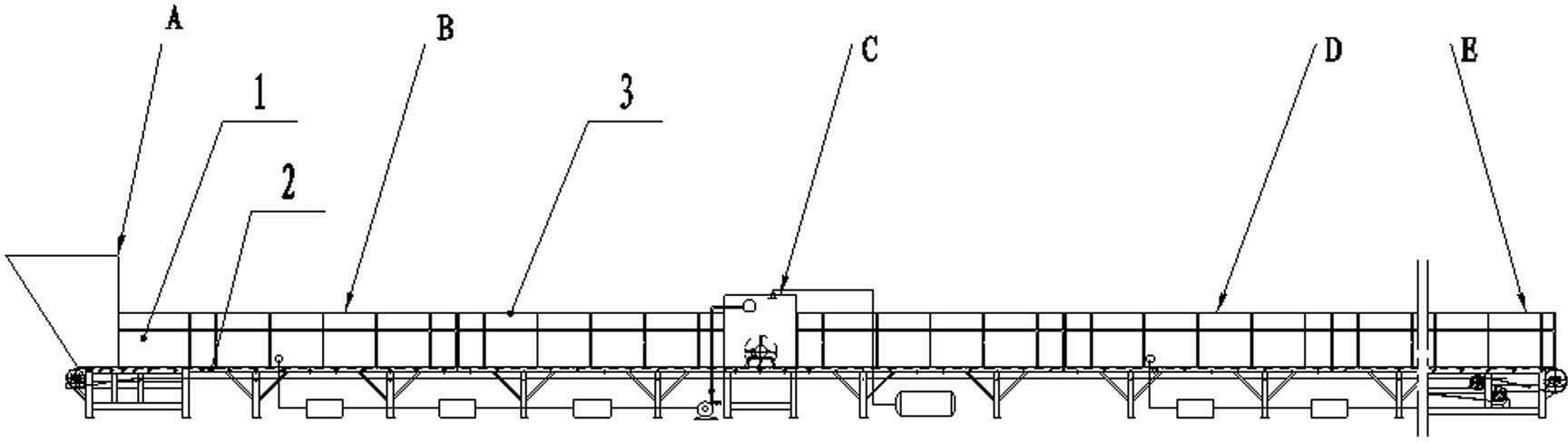

[0017] refer to figure 1 , a kind of method utilizing fermenter to prepare bio-organic fertilizer, comprises the steps:

[0018] (1) Prepare a bio-organic fertilizer fermenter; the fermenter is a sealed tank 1 in the shape of an arch, which is composed of a conveyor belt 2 and a sealed shed 3 arranged on the conveyor belt 2 and connected to the conveyor belt 2. The tank body 1 is generally 40-60 meters long, and the tank is divided into feeding area A, heating and fermentation area B, turning and throwing station C, heat preservation and fermentation area D, turning and throwing station, and fertilizer output area E. The fermentation in the sealed shed 3 The area is also equipped with a heating mechanism, a humidification mechanism, a turning aeration mechanism and a bacteria dosing mechanism;

[0019] (2) Ingredients: mainly composed of the following sludge 60-70% by weight percentage, organic matter 30-40% mixed, plus 2-8 kinds of beneficial bacteria;

[0020] (3) Send the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com