Method for preparing ethylene glycol, propylene glycol and glycerine by carrying out catalytic conversion on corn cobs

A catalytic conversion and corn cob technology, applied in the preparation of propylene glycol and glycerol, and the field of ethylene glycol, can solve the problems of environmental pollution, difficult to carry out, large acid concentration and dosage, and achieve sustainable utilization and pressure relief. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 Production of xylose by acid hydrolysis of corncobs

[0014] Add 200ml of a certain concentration of dilute acid to 25g of 80-100mesh corn cobs, heat to 100°C under constant stirring, and the hydrolysis time is 5h. After hydrolysis, centrifuge the solution, transfer the supernatant to a 500ml volumetric flask, collect the residue after centrifugation and the residue on the filter paper, wash with deionized water, and transfer the washing liquid to the volumetric flask. Finally, the volume was adjusted to 500ml. The residue was dried in a vacuum oven and weighed. The concentration of xylitol is quantitatively analyzed by high-performance liquid chromatography, and the yield of xylose reaches more than 30%.

[0015] The xylose aqueous solution with constant volume for the first time is used as the washing solution for the residue after the second corncob hydrolysis. After the second corn cob hydrolysis, the solution was centrifuged, the supernatant was transf...

Embodiment 2

[0016] Embodiment 2 Preparation of hydrogenation and cracking catalyst

[0017] After dissolving a certain quality of the two metal salt solutions in water, add the dried carrier, stir into a uniform muddy state, immerse at room temperature for 24 hours, and then dry for 12 hours. The prepared catalyst is used for the next conversion experiment after hydrogen reduction or chemical reduction.

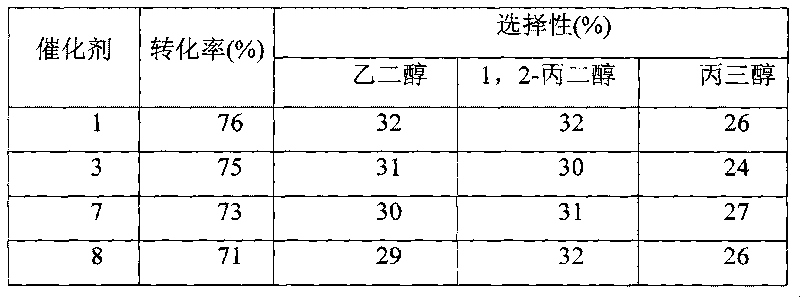

[0018] See Table 1 for details of all prepared catalysts.

[0019] Table 1

[0020] Catalyst number

Embodiment 3

[0021] Example 3 Preparation of xylitol by hydrogenation of xylose aqueous solution

[0022] In this example, the catalytic performance of the prepared catalyst for producing xylitol from xylose at a relatively low temperature was studied.

[0023] Experimental process: 5 g of catalyst and 150 g of 10% xylose aqueous solution were added to a 600 ml autoclave, and the air was replaced 5 times after sealing. Heat the reaction vessel, and when the temperature reaches 90°C, fill it with hydrogen at a pressure of 5 MPa, stir rapidly, and start timing the reaction. After 4 hours, the stirring was stopped, and the hydrogen gas was released after the temperature of the reaction kettle was lowered to room temperature. Sampling analysis, quantitative analysis of xylose and xylitol using liquid chromatography-differential refractive index detector analysis. The catalyst evaluation results are shown in Table 2.

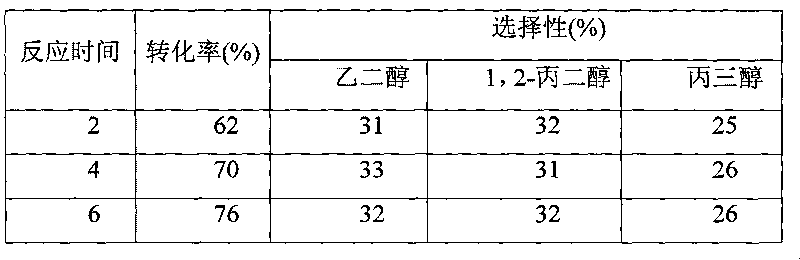

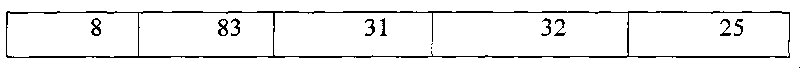

[0024] Table 2

[0025] Numbering

[0026] Numbering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com