Preparation method of cobalt-nickel double metal hydroxide nano composite

A nanocomposite and hydroxide technology, applied in the field of nanomaterial preparation, can solve the problems of unreported catalysts, few cobalt-nickel double metal hydroxides, and few applications, and achieves efficient catalytic hydrogenation of p-nitrophenol, Beneficial for repeated use and mild reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

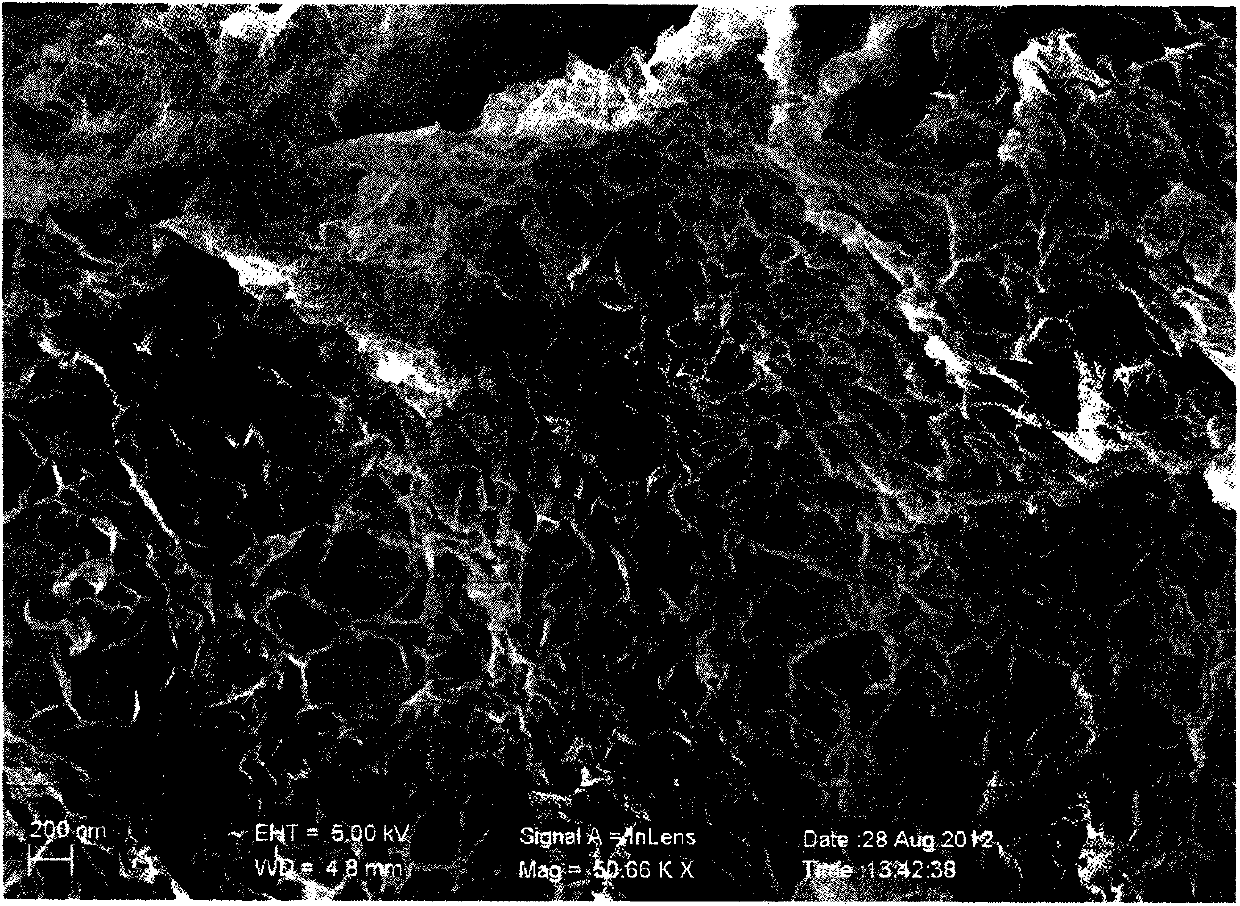

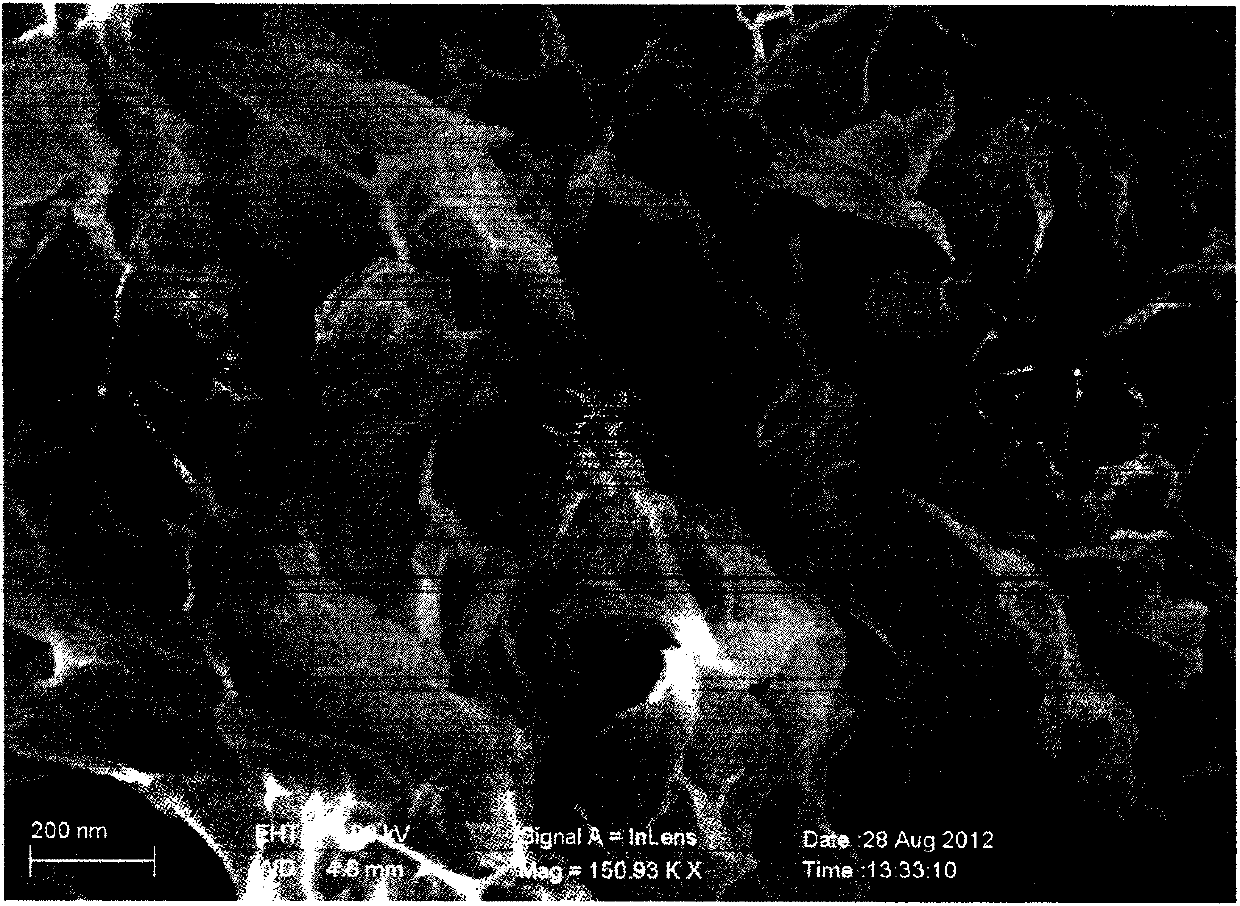

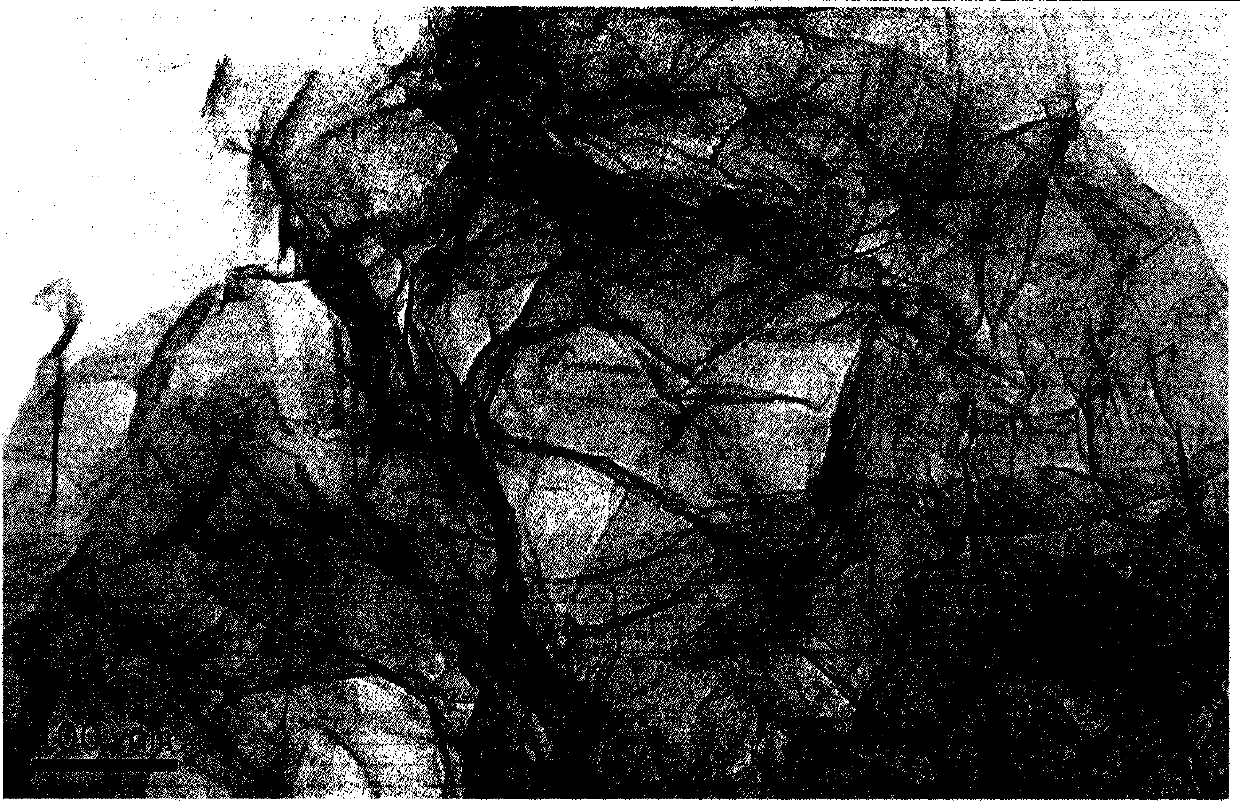

[0032] Embodiment 1: Preparation of graphene-like cobalt-nickel double hydroxide nanocomposites:

[0033] A. Weigh 0.146 grams of cobalt nitrate hexahydrate and 0.200 grams of polyvinylpyrrolidone (PVP) ultrasonically dissolved in 40 milliliters of distilled water, then transfer to a three-necked flask, turn on the electric mixer and set the speed of 1000 rpm to stir the solution.

[0034] B. Under stirring conditions, use a syringe pump to add dropwise 40 ml of newly configured aqueous solution containing 0.750 g of sodium borohydride, and finish adding dropwise in 15 minutes. Subsequently, 40 milliliters of an aqueous solution containing 0.119 grams of nickel chloride hexahydrate was added dropwise with a syringe pump, and the addition was completed in 15 minutes.

[0035] C. After adding all the reagents, the solution was stirred and reacted for one hour. After the reaction, the product obtained was centrifuged and washed three times with distilled water and ethanol, and th...

Embodiment 2

[0040] Embodiment 2: Catalytic p-nitrophenol hydrogenation reaction:

[0041] Add 0.1ml of 0.004M p-nitrophenol solution, 2ml of distilled water, and 1ml of 0.1M freshly prepared sodium borohydride solution to the quartz cuvette in sequence, and the color of the solution immediately changes from light yellow to bright yellow At the same time, the absorption peak was red-shifted from 317 nm to about 400 nm, and then 1 mg of prepared cobalt-nickel double hydroxide nanocomposite was added, and tested with a UV spectrophotometer at 200-500 nm every 1 minute , there is no obvious change until the peak around 400 nm.

[0042] Shimadzu UV-1750 ultraviolet spectrophotometer was used to test the catalytic properties of p-nitrophenol hydrogenation of the samples.

[0043] Figure 7 , Figure 8 Be the ultraviolet-visible absorption curve that the product of this example catalyzes p-nitrophenol hydrogenation at room temperature, by Figure 7 It can be seen that after adding 1 ml of fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com