Nano vanadium carbide ferrofluid and preparation method thereof

A vanadium carbide and ferrofluid technology, applied in the fields of magnetic liquid, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of ferromagnetism that cannot be eliminated, magnetic fluid instability, and magnetic performance degradation, and achieves the suppression of crystal grains. The effect of growing up, preventing agglomeration and settling, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

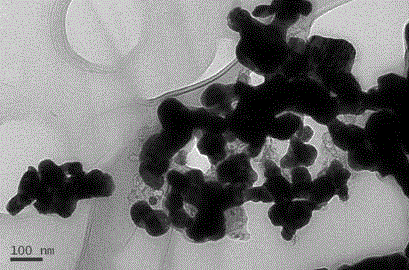

[0024] Weigh 30g of vanadium trioxide and 12g of anhydrous glucose, dissolve them in deionized water at 80°C, and mix the raw materials thoroughly with electric stirring, then prepare the precursor required for carbonization by spray drying. Put the precursor powder into a tube-type atmosphere furnace, pass in hydrogen for carbonization, hold at 550°C for 1 hour, then rise to the carbonization temperature of 1200°C, the heating rate is 10°C / min, and the carbonization holding time is 3 hours. The vanadium carbide particles prepared after carbonization were high-energy ball milled in a stainless steel ball mill jar for 6 hours, the ball-to-material ratio was 10:1, and the speed was 400r / min. Using the sedimentation effect of a strong magnetic field, the nano-magnetic vanadium carbide particles are repeatedly washed with secondary deionized water and absolute ethanol to remove residual carbon and other non-magnetic impurities, and then added to a certain proportion of base liquid ...

Embodiment 2

[0026] Weigh 20 g of ammonium metavanadate and 8 g of anhydrous glucose, dissolve them in deionized water at 80 ° C, and mix the raw materials thoroughly with electric stirring, then prepare the precursor required for carbonization by spray drying. Put the precursor powder into a tube-type atmosphere furnace, pass in hydrogen for carbonization, hold at 550°C for 1 hour, then rise to the carbonization temperature of 1150°C, the heating rate is 8°C / min, and the carbonization holding time is 4 hours. The vanadium carbide particles prepared after carbonization were high-energy ball milled in a stainless steel ball mill jar for 7 hours, the ball-to-material ratio was 10:1, and the speed was 400r / min. Using the sedimentation effect of a strong magnetic field, the nano-magnetic vanadium carbide particles are repeatedly washed with secondary deionized water and absolute ethanol to remove residual carbon and other non-magnetic impurities, and then added to a certain proportion of base l...

Embodiment 3

[0028]Weigh 30g of ammonium polyvanadate and 15g of anhydrous glucose, dissolve them in deionized water at 80°C, and mix the raw materials thoroughly with electric stirring, then prepare the precursor required for carbonization by spray drying. Put the precursor powder into a tube-type atmosphere furnace, pass in hydrogen for carbonization, hold at 550°C for 1 hour, and then rise to the carbonization temperature of 1300°C, the heating rate is 10°C / min, and the carbonization holding time is 2.5 hours. The vanadium carbide particles prepared after carbonization were high-energy ball milled in a stainless steel ball mill tank for 8 hours, the ball-to-material ratio was 10:1, and the speed was 400r / min. Using the sedimentation effect of a strong magnetic field, the nano-magnetic vanadium carbide particles are repeatedly washed with secondary deionized water and absolute ethanol to remove residual carbon and other non-magnetic impurities, and then added to a certain proportion of ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com