Manufacturing method of induction heating ceramic tableware

A technology of induction heating and production methods, which can be used in applications, clay products, household appliances, etc., and can solve the problems of gray appearance, harm, and low texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

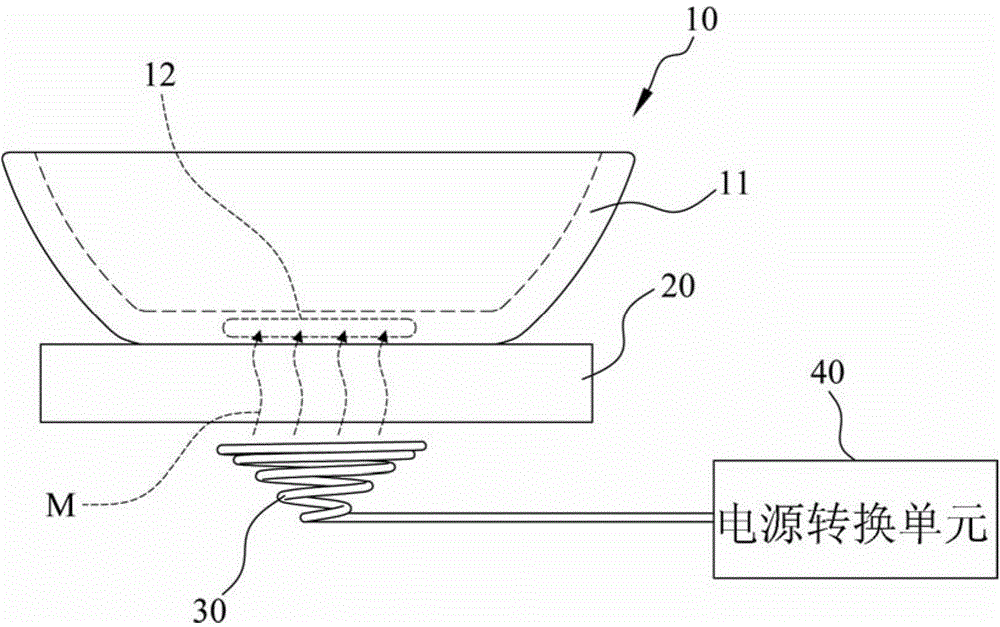

[0032] The embodiments of the present invention will be described in more detail below in conjunction with icons and component symbols, so that those skilled in the art can implement them after studying this specification.

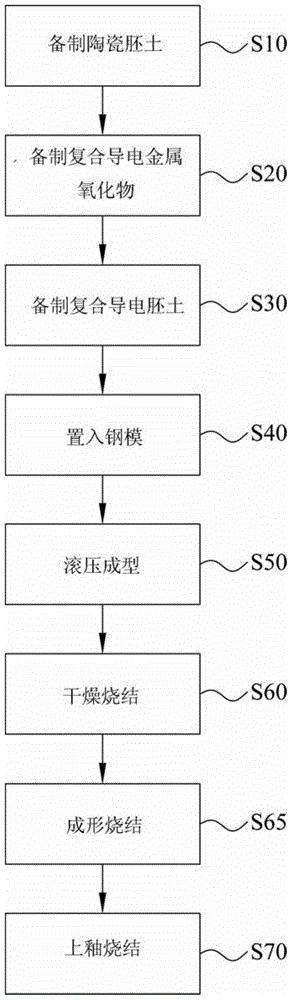

[0033] refer to figure 1 , a schematic diagram of the operation flow of the method for manufacturing induction heating ceramic tableware according to the present invention. Such as figure 1 As shown, the production method of the induction heating ceramic tableware of the present invention mainly includes the steps S10, S20, S30, S40, S50, S60, S65 and S70 in order to produce the induction heating ceramic tableware, and the induction heating ceramic tableware has conductive Sex, and can induce external electromagnetic waves to generate eddy current, and then convert the electric energy of eddy current into heat energy by its own resistance effect to generate heat.

[0034] First of all, the manufacturing method of the present invention is that in step S10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com