Preparation method of mono-dispersion polysiloxane microspheres with controllable particle size

A polysiloxane and monodispersity technology is applied in the field of preparation of polysiloxane microspheres, which can solve the problems of increased preparation cost and difficulty in washing, siloxane is prone to explosion, and product quality is uneven, etc. Guarantee the effects of monodispersity, high product yield, and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

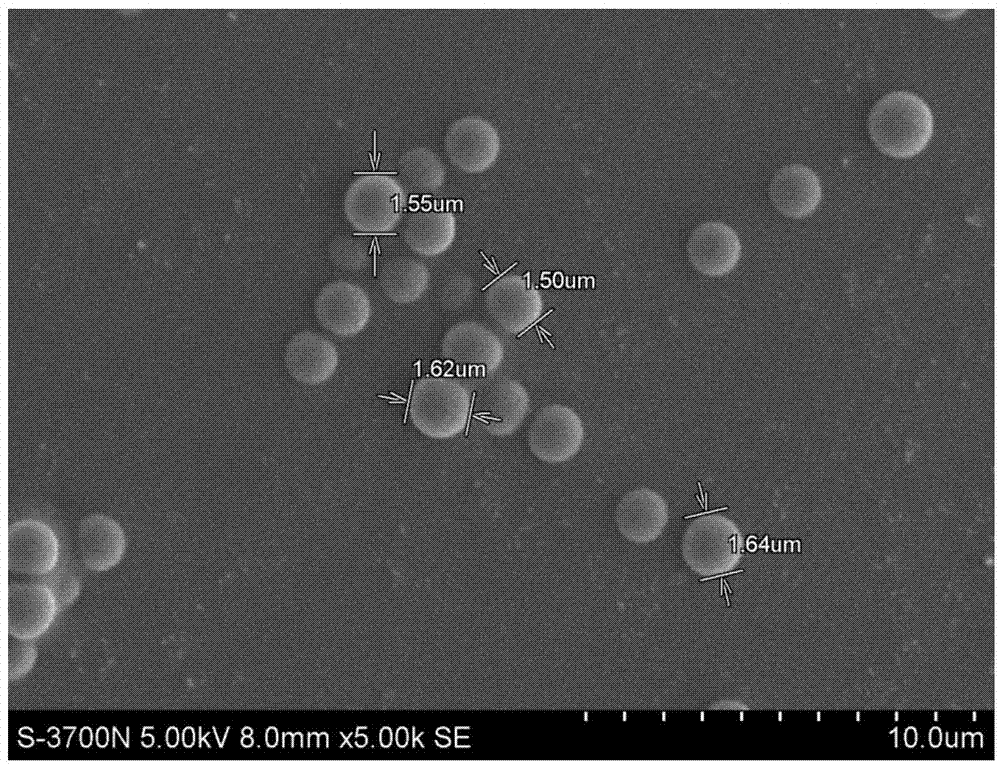

[0023] Add 3Kg of deionized water into the reaction kettle, add 70% concentration of acetic acid aqueous solution, adjust the pH value of the aqueous solution to 4, then add 0.6KG of methyltrimethoxysilane, and stir and react at a speed of 200r / min for 2 hours. Then add 70% concentration of sodium hydroxide aqueous solution, adjust the pH of the solution to 11, stir and react for 1 hour under the rotating speed of 20r / min, the solution after the reaction is centrifuged, and with 30% ethanol aqueous solution (the mixing of ethanol and deionized water , the same below) for washing, placed in a vacuum drying oven to dry for 6 hours, the particle size of the obtained microspheres is about 1.5 microns, such as figure 1 shown.

Embodiment 2

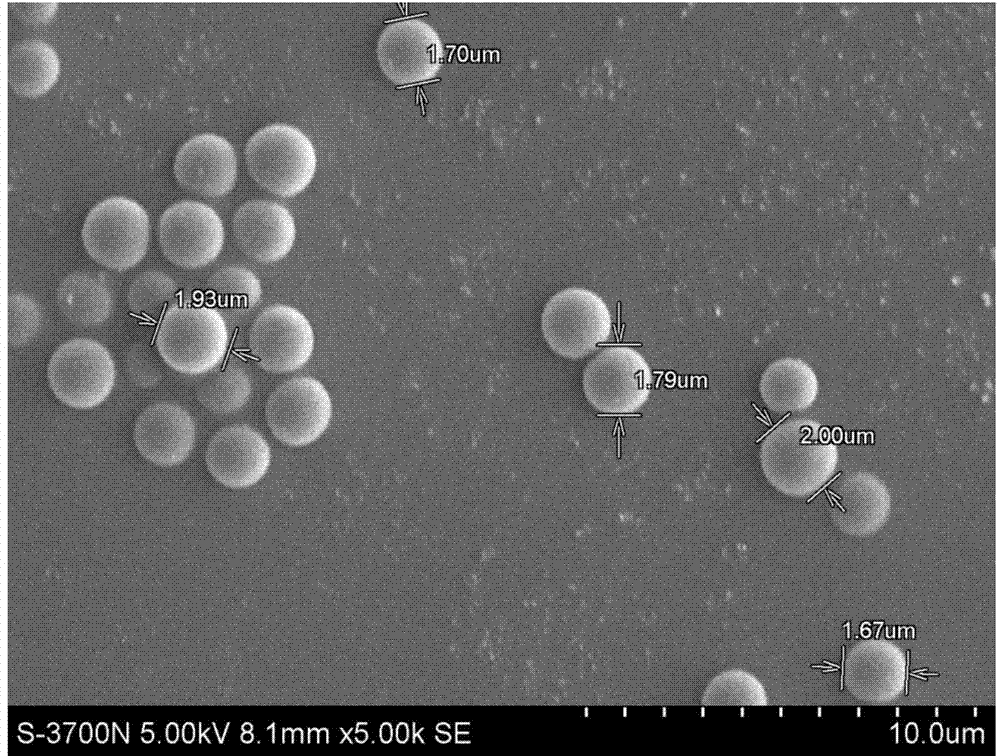

[0025] Add 7Kg of deionized water to the reaction kettle, add 85% phosphoric acid aqueous solution, adjust the pH of the aqueous solution to 3, then add 0.7KG of methyltrimethoxysilane, stir and react at 150r / min for 1.5 hours, then add ammonia aqueous solution, adjust the pH of the solution to 9, stir and react at a speed of 30r / min for 2 hours, centrifuge the reacted solution, wash it with 20% ethanol aqueous solution, put it into a vacuum drying oven and dry it for 5 hours, and the obtained microspheres The particle size is about 2 microns.

Embodiment 3

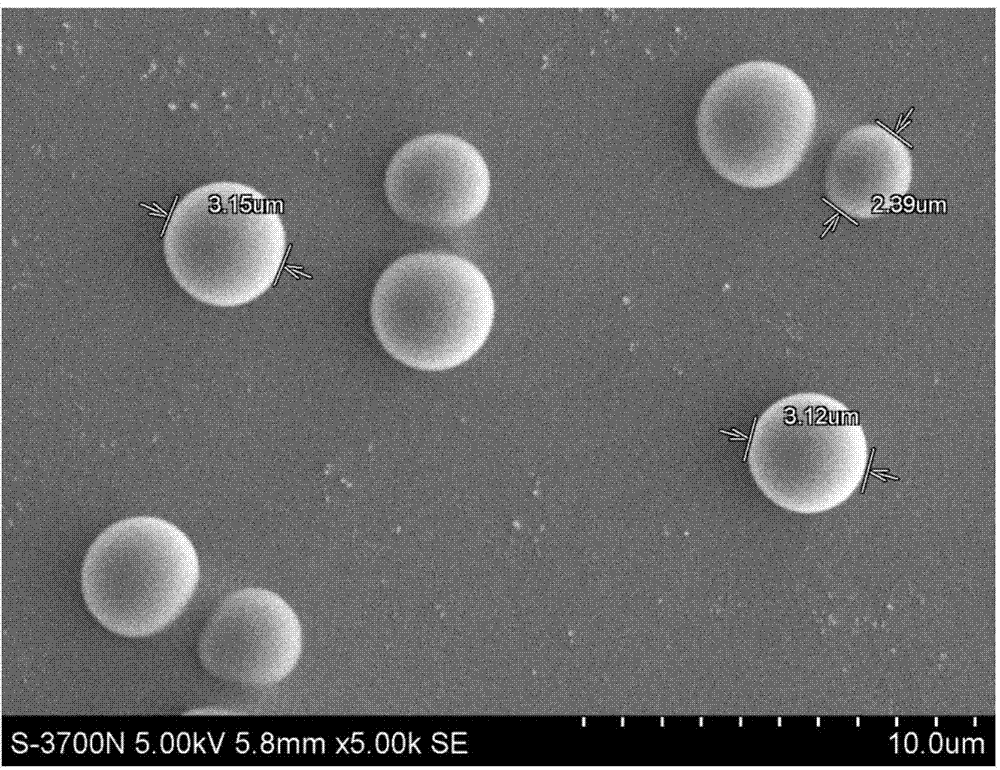

[0027] Add 7Kg of deionized water into the reaction kettle, add concentrated hydrochloric acid, adjust the pH of the aqueous solution to 2, then add 0.35KG of methyltrimethoxysilane, stir and react at a speed of 200r / min for 0.5 hours, then add triethylamine aqueous solution, adjust the pH of the solution to 8, stir and react at a speed of 40r / min for 3 hours, centrifuge the reacted solution, wash it with 15% ethanol aqueous solution, put it into a vacuum drying oven and dry it for 4 hours, and the obtained microspheres The particle size is about 2-3 microns, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com