A direct method to prepare molecularly imprinted tio2/wo3 composite photocatalyst with visible light response

A technology of molecular imprinting and visible light, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low selectivity, expensive preparation materials, and complicated preparation processes and other problems, to achieve obvious economic benefits, high visible light activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Put 10mL of butyl titanate, 13mL of absolute ethanol, 2mL of glacial acetic acid and 0.4 g of 2-nitrophenol into an iodine flask, and call this liquid A liquid. In addition, mix 6mL absolute ethanol, 6mL glacial acetic acid and 4mL water evenly, and this mixture is B solution.

[0033] (2) Slowly drop liquid B into liquid A under vigorous stirring. After the dropwise addition, 5 mL of ammonium tungstate solution with a concentration of 0.014 mol / L was added dropwise while stirring. Stirring was continued for 3h, and the resulting sol was aged. The liquid loses its fluidity and becomes a wet gel.

[0034] (3) Dry the wet gel at 100°C for 12 hours to obtain a yellow gel block, which is ground to obtain a powder.

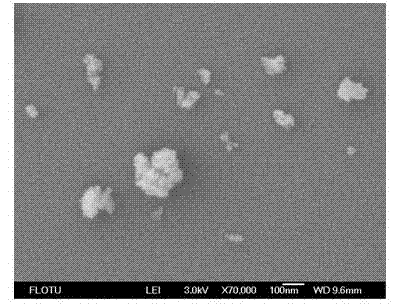

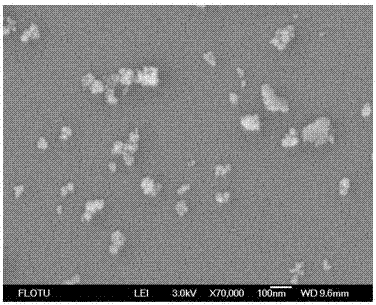

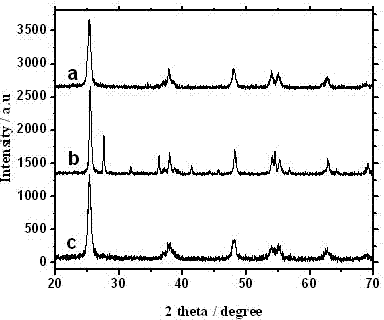

[0035] (4) Put the powder into a muffle furnace and calcinate at 500 °C for 3 h to remove the template molecules, and the TiO 2 Imprinted holes are left on the surface, while ammonium tungstate decomposes into WO 3 , Molecularly imprinted TiO was obtain...

Embodiment 2

[0037] (1) Put 10mL of ethyl titanate, 13mL of absolute ethanol, 2mL of glacial acetic acid and 0.4 g of 2-nitrophenol into an iodine flask, and call this liquid A liquid. In addition, mix 6mL absolute ethanol, 6mL glacial acetic acid and 4mL water evenly, and this mixture is B solution.

[0038] (2) Slowly drop liquid B into liquid A under vigorous stirring. After the dropwise addition, 5 mL of ammonium tungstate solution with a concentration of 0.014 mol / L was added dropwise while stirring. Stirring was continued for 3h, and the resulting sol was aged. The liquid loses its fluidity and becomes a wet gel.

[0039] (3) Dry the wet gel at 100°C for 12 hours to obtain a yellow gel block, which is ground to obtain a powder.

[0040] (4) Put the powder into a muffle furnace and calcinate at 500 °C for 3 h to remove the template molecules, and the TiO 2 Imprinted holes are left on the surface, while ammonium tungstate decomposes into WO 3 , Molecularly imprinted TiO was obtain...

Embodiment 3

[0042] (1) Put 10mL of isopropyl titanate, 13mL of absolute ethanol, 2mL of glacial acetic acid and 0.4 g of 2-nitrophenol into an iodine flask, and call this liquid A liquid. In addition, mix 6mL absolute ethanol, 6mL glacial acetic acid and 4mL water evenly, and this mixture is B solution.

[0043] (2) Slowly drop liquid B into liquid A under vigorous stirring. After the dropwise addition, 5 mL of ammonium tungstate solution with a concentration of 0.014 mol / L was added dropwise while stirring. Stirring was continued for 3h, and the resulting sol was aged. The liquid loses its fluidity and becomes a wet gel.

[0044] (3) Dry the wet gel at 100°C for 12 hours to obtain a yellow gel block, which is ground to obtain a powder.

[0045] (4) Put the powder into a muffle furnace and calcinate at 500 °C for 3 h to remove the template molecules, and the TiO 2 Imprinted holes are left on the surface, while ammonium tungstate decomposes into WO 3 , Molecularly imprinted TiO was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com