Pretreatment method capable of improving saccharification efficiency of lignocellulose

A technology of lignocellulose and saccharification efficiency, applied in the field of biofuel preparation, can solve the problems of high processing temperature and low yield of reducing sugar, and achieve the effect of simple processing process, low equipment requirements and high enzymatic saccharification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Wash the rice straw with a particle size of 180-400 μm in clear water, and dry it at 55° C. to constant weight;

[0032] (2) After mixing 5% (W / W) distilled water with 0.5:1:1 mixed oxalic acid / glycerol / choline chloride and sealing it, place it in a drying oven at 100°C until it is evenly mixed into a transparent liquid reserve;

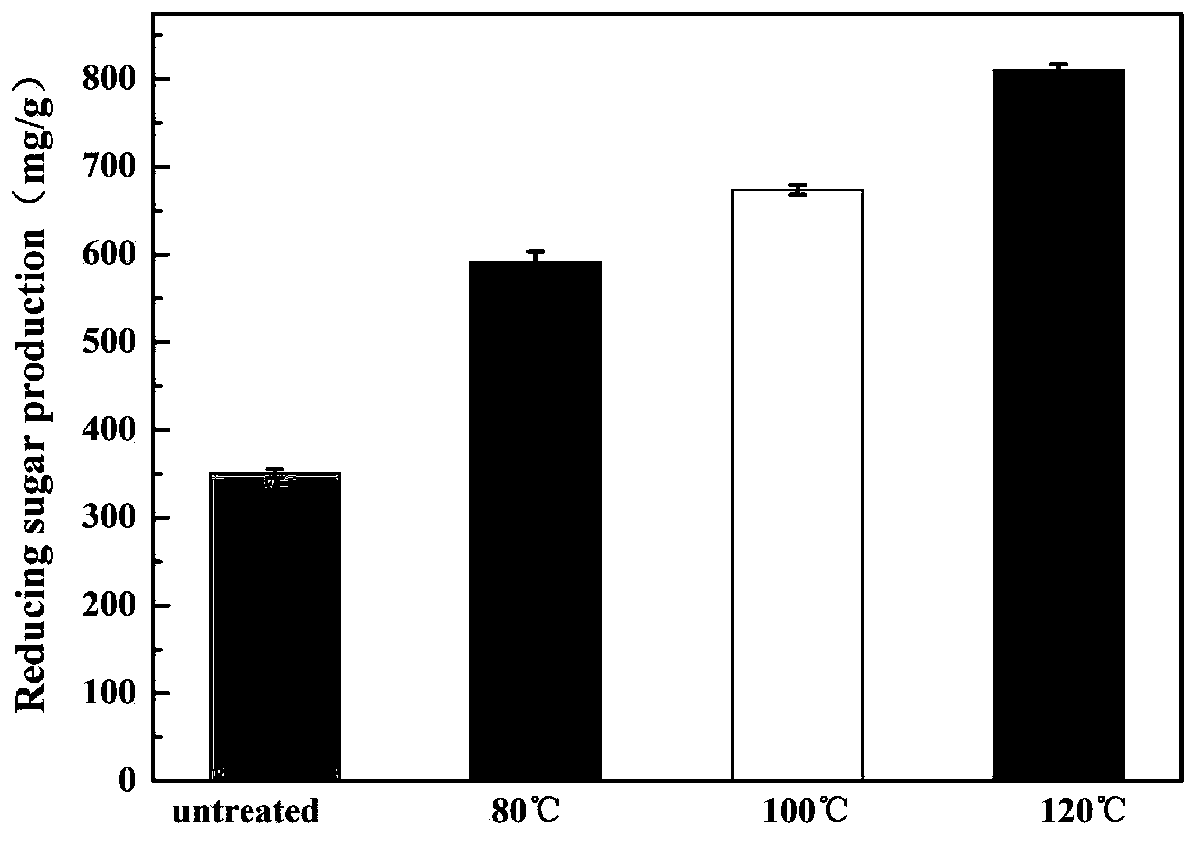

[0033] (3) Mix and oscillate 10% (W / W) of rice straw with the new organic solvent in (2) in a shaker at 80°C, 100°C, and 120°C for 4 hours for pretreatment, and then wash the filter residue until the lotion is neutral. Dry the filter residue to obtain three pretreated samples, 1;

[0034] (4) After mixing 22 FPU / g substrate cellulase and 25 mg / mL pretreated sample with citrate buffer (pH 4.80, 0.1 mol / L), enzymolyze 22 at 100 rpm / min at 50°C ~72h, sampling every 24 hours to measure the amount of reducing sugar produced.

[0035] After being treated in this embodiment, the reducing sugar content released by rice straw can be increased fr...

Embodiment 2

[0037] (1) Wash the rice straw with a particle size of 180-400 μm in clear water, and dry it at 55° C. to constant weight;

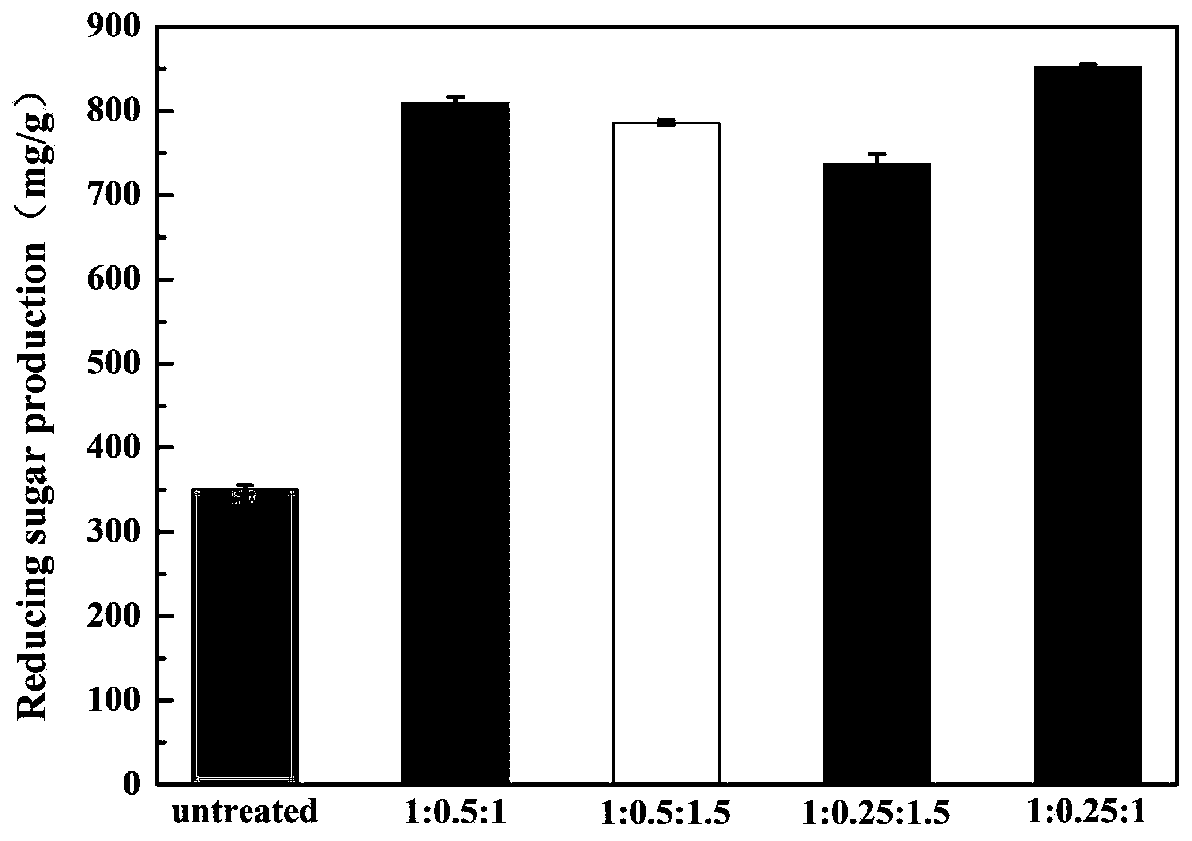

[0038] (2) With 5% (W / W) distilled water and 0.25:1:1, 0.5:1:1, 0.25:1:1.5, 0.5:1:1.5 oxalic acid / glycerol / choline chloride After mixing and sealing, put it in a drying oven at 100°C, and wait until it becomes a transparent liquid for later use;

[0039] (3) Mix and oscillate 10% (W / W) of rice straw with the new organic solvent in (2) for pretreatment in a shaker at 120°C for 4 hours, then wash the filter residue until the washing solution is neutral, and dry the filter residue to obtain 4 A pretreatment sample, 2;

[0040] (4) After mixing 22 FPU / g substrate cellulase and 25 mg / mL pretreated sample with citrate buffer (pH 4.80, 0.1 mol / L), enzymolyze 22 at 100 rpm / min at 50°C ~72h, sampling every 24 hours to measure the amount of reducing sugar produced.

[0041] After the treatment in this example, the content of reducing sugar released from rice st...

Embodiment 3

[0043] (1) Wash the rice straw with a particle size of 180-400 μm in clear water, and dry it at 55° C. to constant weight;

[0044] (2) After mixing 5% (W / W) distilled water with 0.25:1:1 mixed oxalic acid / glycerol / choline chloride and sealing it, place it in a drying oven at 100°C until it is evenly mixed into a transparent liquid reserve;

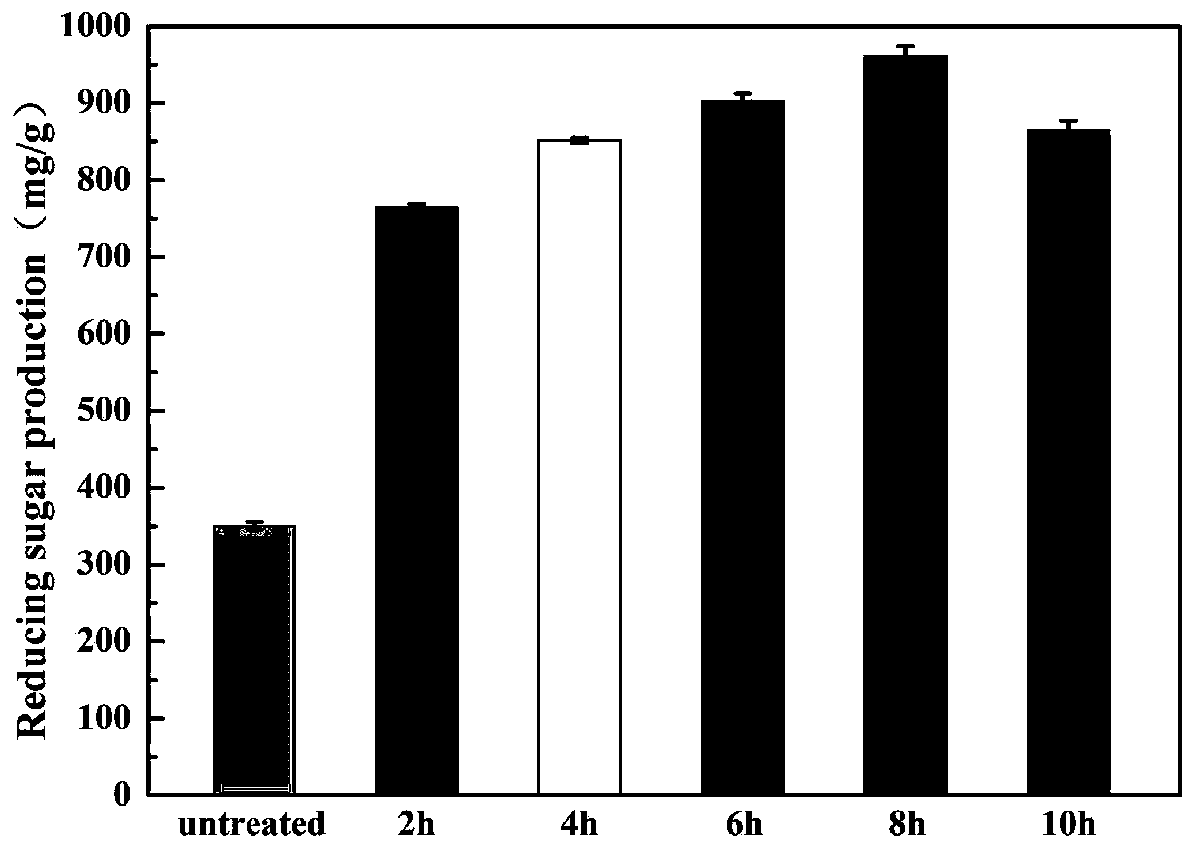

[0045] (3) Mix and oscillate 10% (W / W) of rice straw with the new organic solvent in (2) in a shaker at 120°C for 2, 4, 6, 8, and 10 hours for pretreatment, and then wash the filter residue into the lotion properties, drying the filter residue, and obtaining 5 kinds of pretreated samples 3;

[0046] (4) After mixing 22 FPU / g substrate cellulase and 25 mg / mL pretreated sample with citrate buffer (pH 4.80, 0.1 mol / L), enzymolyze 22 at 100 rpm / min at 50°C ~72h, sampling and measuring sugar production every 24 hours.

[0047] After being treated in this embodiment, the reducing sugar content released by rice stalks increased from 350.661mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com