A kind of production process of glutinous corn rice wine

A production process, technology of waxy corn, applied in the field of production process of waxy corn rice wine, can solve the problem of high content of ethyl carbamate, achieve the effects of improving saccharification efficiency, optimizing fermentation conditions, and ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

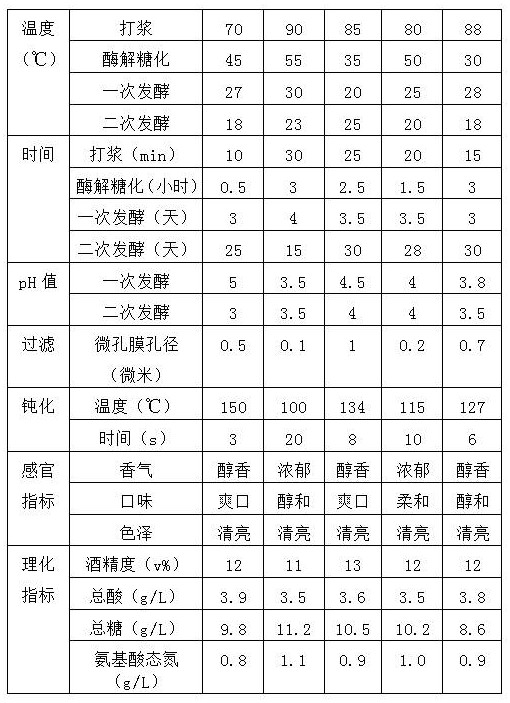

Image

Examples

Embodiment 1

[0022] A kind of glutinous corn rice wine production process, concrete production steps are as follows in the laboratory:

[0023] 1) Waxy corn beating: put waxy corn seeds with a water content of 10% after degerming and cleaning, and put them into a household wall-breaking beater with a capacity of 2L. The weight ratio is waxy corn: water = 1:3 Add water, make a slurry, pass the turbid liquid containing solid particles through a 70-mesh sieve, and keep the obtained waxy corn syrup at 80°C for 20 minutes;

[0024] 2), enzymatic hydrolysis and saccharification: move the waxy corn syrup obtained in step 1) to a laboratory glass enzymolysis tank with a capacity of 2L, add the pre-prepared compound enzyme preparation, the addition amount is 500ppm, and heat at 45°C Keep it under the pressure for 2 hours, and the stirring rate is 30 rpm. The above-mentioned compound enzyme preparation is prepared according to the ratio of glucoamylase: neutral protease: cellulase: lipase=6:1:1:0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com