Martensitic stainless steel rod for automobile turbocharger rivet

A martensitic stainless steel and turbocharger technology, applied in the field of stainless steel bars, can solve the problems of large fluctuations in quenching hardness and depth of hardened layer, low qualification rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The chemical composition is: C: 0.12%, Si: 0.1%, Mn: 0.1%, P: 0.02%, S: 0.02%, Cr: 15.00%, Ni: 1.50%, N: 0.01%, B: 0.0001%, I The amount is Fe and unavoidable impurities. Vacuum induction melting or non-vacuum melting is used to cast steel ingots according to the above-mentioned composition ratio. The steel ingots are demoulded after 24 hours. The heating temperature of the steel ingots is 1100°C and the heating time is 80 minutes. After the steel ingots are heated, they are forged. ℃, the forging specification is 85mm×85mm billet, after forging, the billet is bundled and stacked together for cooling; the surface of the billet is peeled with a grinding wheel, and the surface oxide scale and defects are removed, and the peeling depth is 1-3mm; the peeled billet Put it into the heating furnace for heating, the steel ingot heating temperature is 1120°C, and the heating time is 60min; after the billet is heated, it is rolled, the starting rolling temperature is 1050°C, the ...

Embodiment 2

[0036] The chemical composition is: C: 0.13%, Si: 0.2%, Mn: 0.2%, P: 0.025%, S: 0.022%, Cr: 15.5%, Ni: 1.60%, N: 0.015%, B: 0.0001%, I The amount is Fe and unavoidable impurities. Vacuum induction melting or non-vacuum melting is adopted according to the above-mentioned composition ratio, and the steel ingot is cast. The steel ingot is demoulded after 24 hours. The heating temperature of the steel ingot is 1120°C, and the heating time is 90 minutes. After the steel ingot is heated, it is forged. ℃, the forging specification is 85mm×85mm billet, after forging, the billet is bundled and stacked together for cooling; the surface of the billet is peeled with a grinding wheel, and the surface oxide scale and defects are removed, and the peeling depth is 1-3mm; the peeled billet Put it into the heating furnace for heating, the steel ingot heating temperature is 1150°C, and the heating time is 80min; after the billet is heated, it is rolled, the starting rolling temperature is 1050°C...

Embodiment 3

[0038] The chemical composition is: C: 0.15%, Si: 0.2%, Mn: 0.3%, P: 0.012%, S: 0.015%, Cr: 15.5%, Ni: 2.50%, N: 0.05%, B: 0.0005%, I The amount is Fe and unavoidable impurities. Vacuum induction melting or non-vacuum melting is used according to the above-mentioned composition ratio, and the steel ingot is cast. The steel ingot is demoulded after 24 hours. The heating temperature of the steel ingot is 1150°C, and the heating time is 90 minutes. After the steel ingot is heated, it is forged. ℃, the forging specification is 85mm×85mm billet, after forging, the billet is bundled and stacked together for cooling; the surface of the billet is peeled with a grinding wheel, and the surface oxide scale and defects are removed, and the peeling depth is 1-3mm; the peeled billet Put it into the heating furnace for heating, the steel ingot heating temperature is 1100°C, and the heating time is 80min; after the billet is heated, it is rolled, the starting rolling temperature is 1050°C, th...

PUM

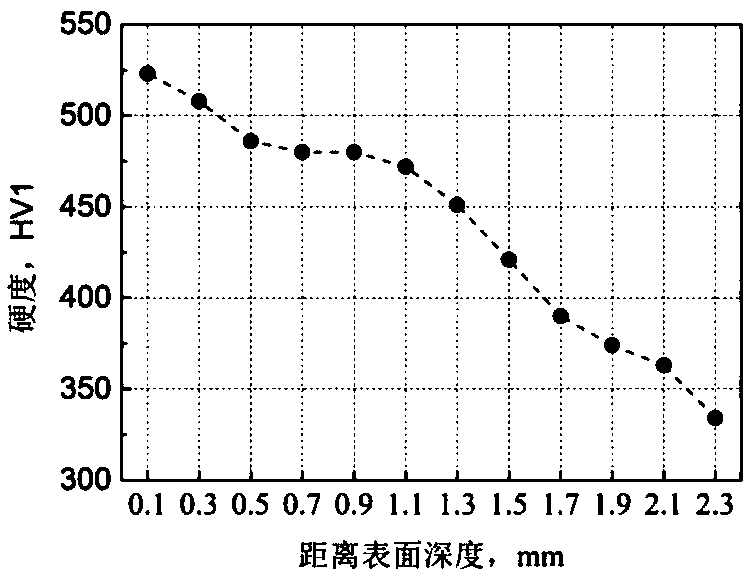

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com