Equipment for automatic riveting butt jointed seal ring of separability type hard disk drive

The technology of a hard disk drive and riveting device is applied in the field of automatic riveting device for the butt joint sealing ring of a detachable hard disk drive. The effect of workload, depth stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

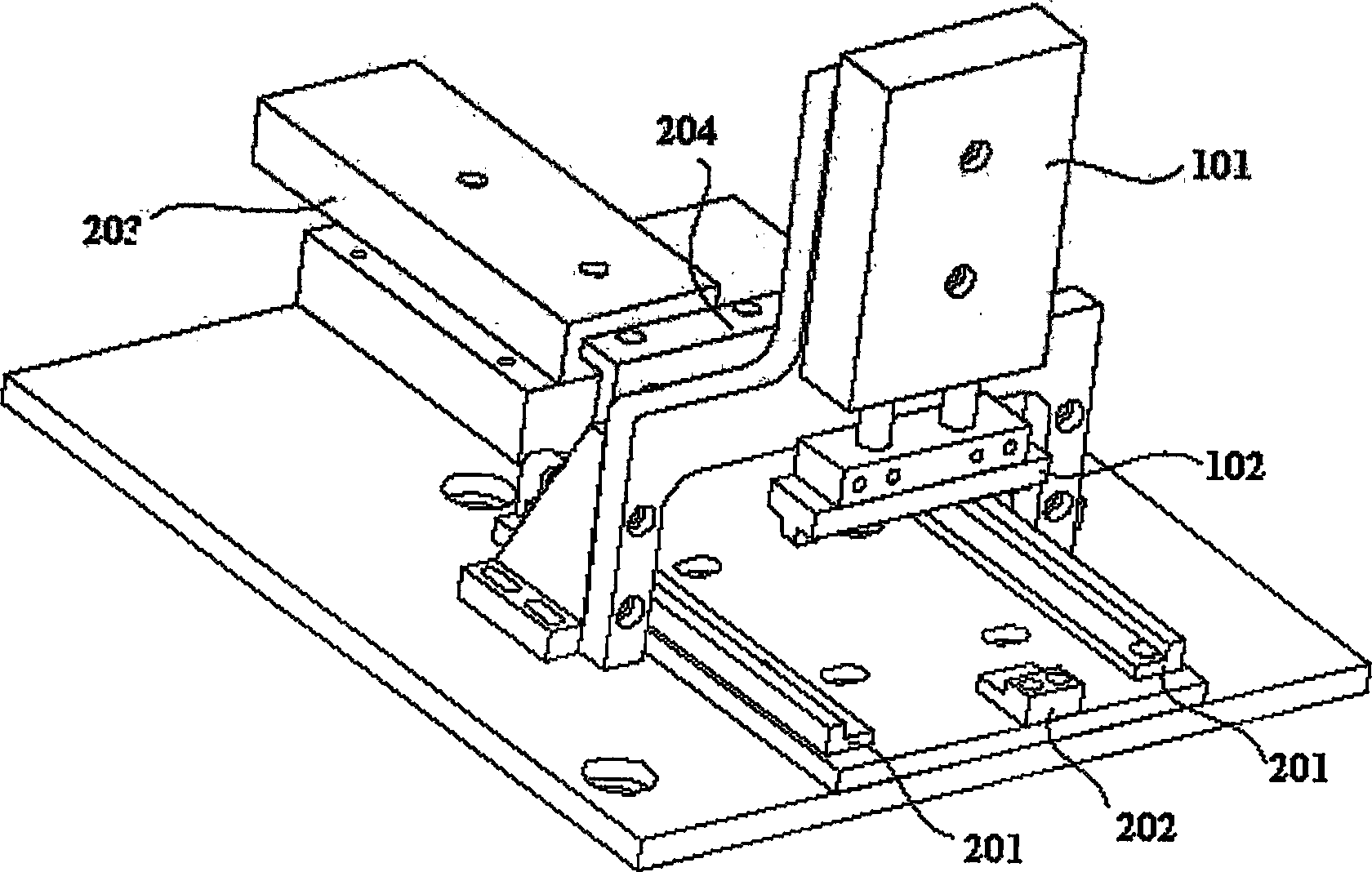

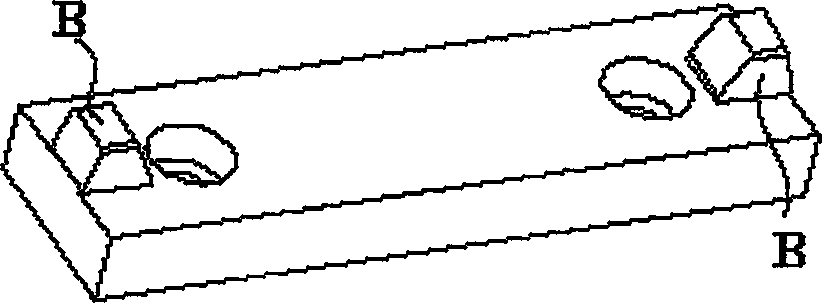

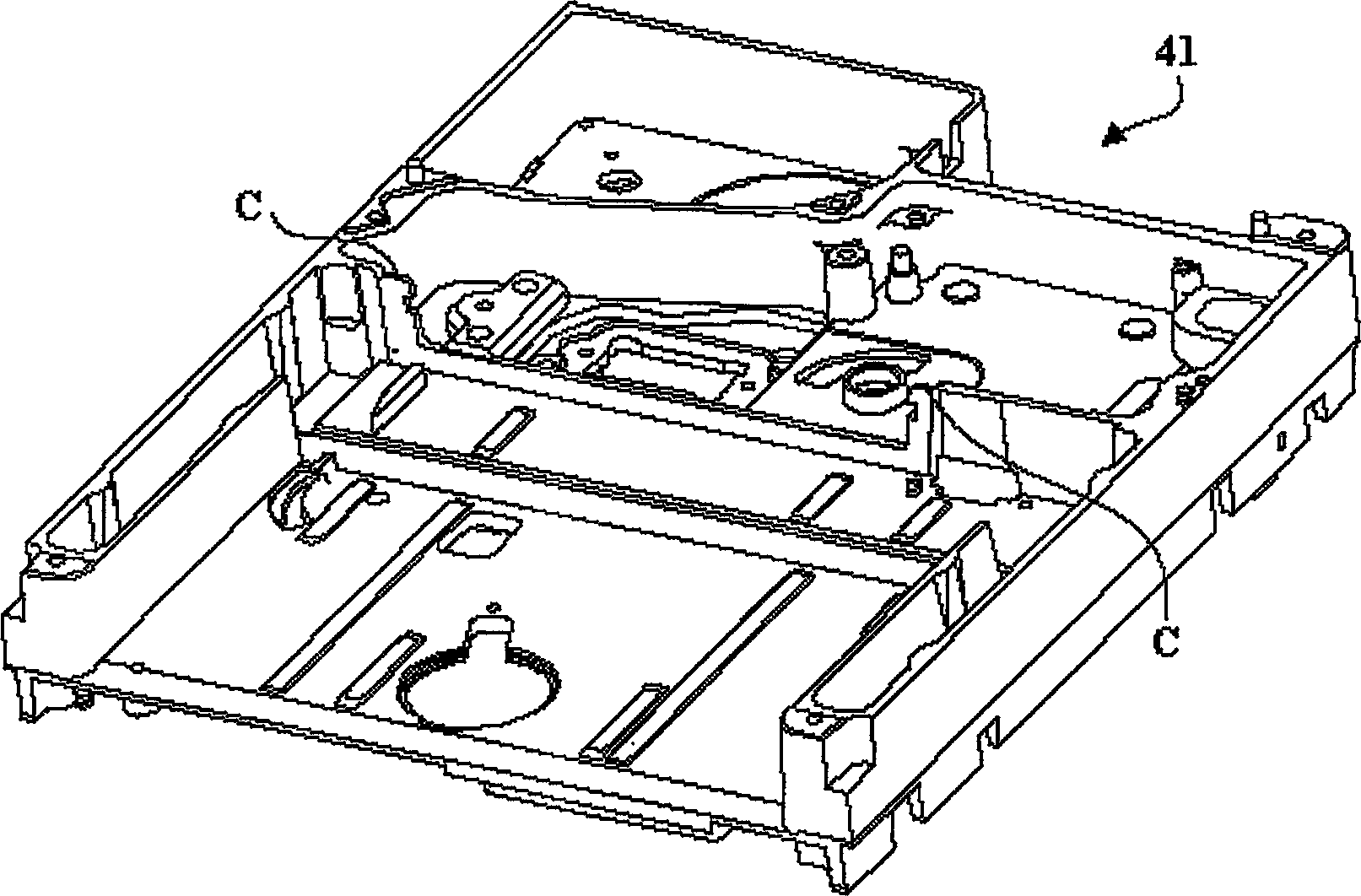

[0017] An automatic riveting device for a detachable hard disk drive butt joint sealing ring, such as figure 1 As shown, it includes a cylinder 101 as a driving mechanism, a movable head 102, and an antistatic shield (for the convenience of observing the movable head 1, not in figure 1 Draw in), limit groove 201, block 202, as the cylinder 203 of driving mechanism two, movable head two 204 and metal inductor (not in figure 1 drawn in). The assembled driver and butt joint sealing ring are respectively as follows: image 3 , 4 shown.

[0018] Limiting groove 201, stop block 202, cylinder 203 and movable head two 204 are used as fixing device, and the inner width of limit groove 201 is adapted to the width of driver shell seat 41 installed, and stopper 202 and movable head two 204 are respectively positioned at limit At the two ends of the position groove 201, two metal arms parallel to the limit groove 201 are arranged on the movable head 204. Moving against portion A keeps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com