An integrated equipment for erecting and installing pp pipes

A technology of equipment and pipelines, which is applied in the field of PP pipeline erection and installation integrated equipment, can solve the problems of reducing the time and scope of work activities, manual sockets, casualties, etc., and achieve the reduction of time and scope of work activities, stable socket depth and Speed, effect that meets depth and strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

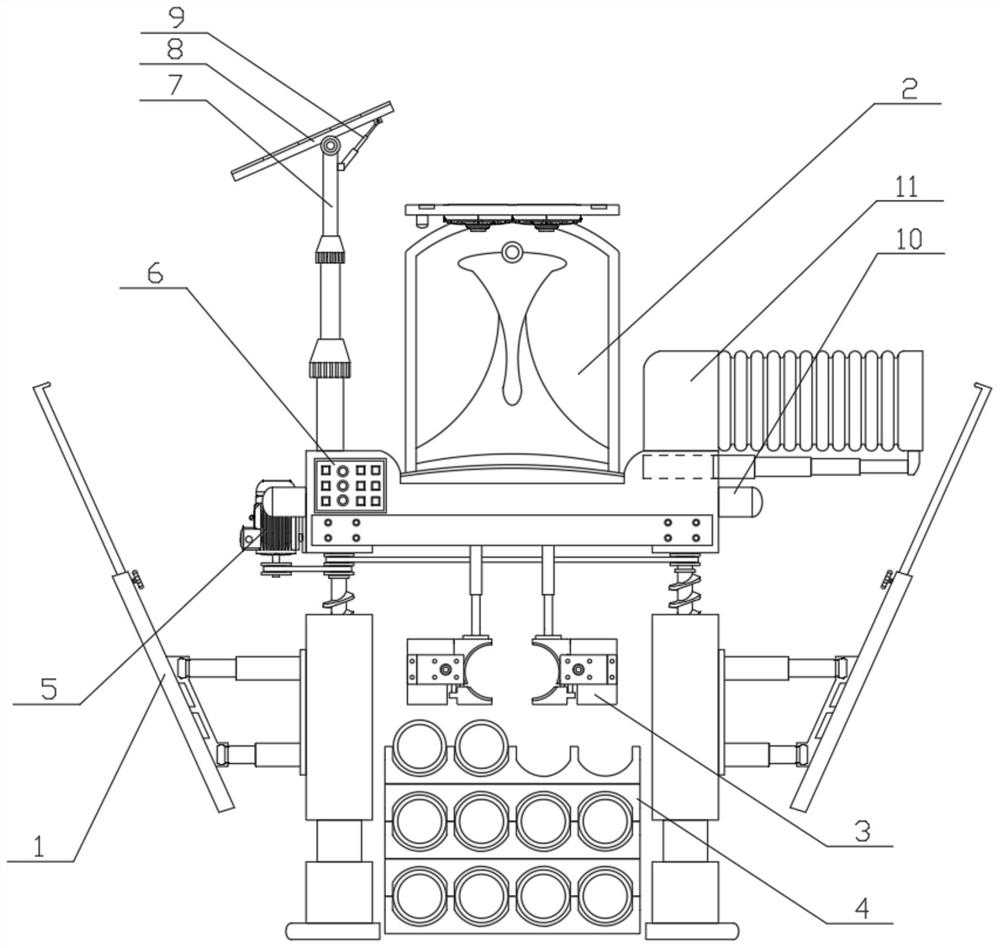

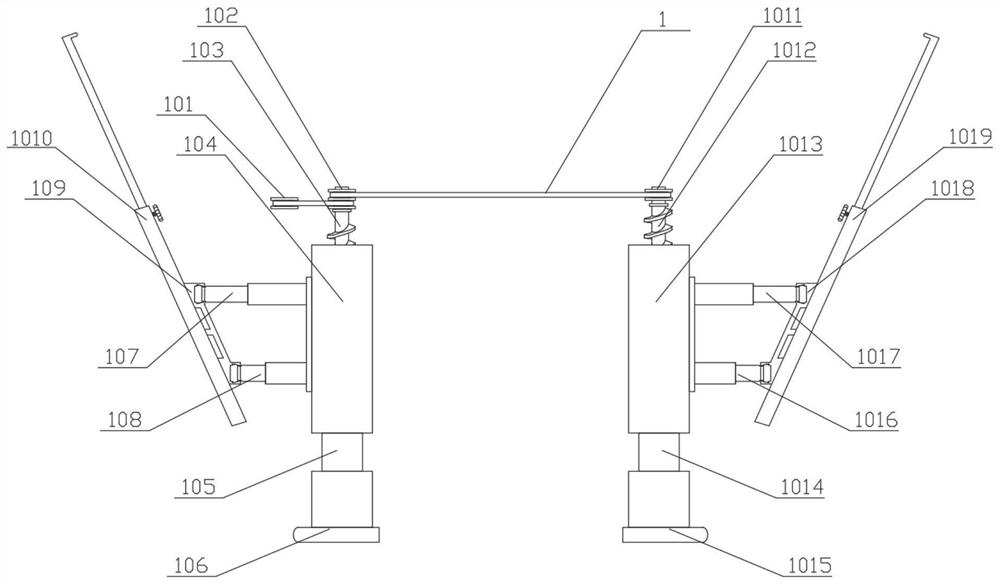

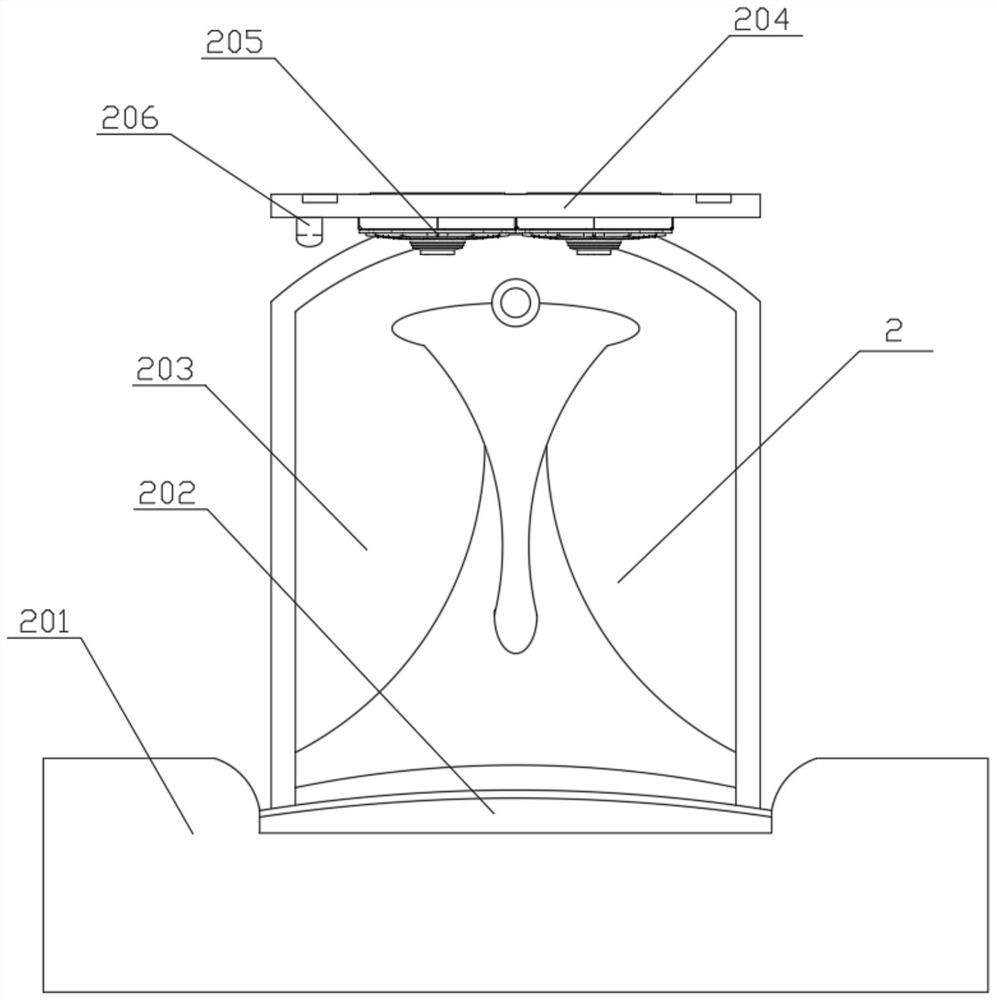

[0029] In this technical solution:

[0030] Support transfer mechanism-1, sun protection work chair-2, socket type automatic socket device-3, pipe pillow rebound placement box-11, transmission wheel-101, double transmission wheel-102, first lifting screw rod-103 , the first support leg-104, the first gas-hydraulic booster cylinder-105, the first decompression base-106, the first hydraulic cylinder-107, the second hydraulic cylinder-108, the first double-track slide plate-109, the first bearing Press moving plate-1010, driven wheel-1011, second lifting screw-1012, second support leg-1013, second gas-hydraulic booster cylinder-1014, second decompression base-1015, third hydraulic cylinder-1016 , The fourth hydraulic cylinder-1017, the second double-track slide plate-1018, the second pressure-bearing moving plate-1019, the workbench-201, the breathable cushion-202, the seat back panel-203, the sunshade top plate-204, the cooling fan- 205, safety handle-206, slide rail fixing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com