Apparatus and method for bonding sheet, and apparatus and method for manufacturing sheet

A sheet pasting device and adhesive sheet technology, applied in the sheet pasting device and pasting, as well as the sheet manufacturing device and manufacturing field, can solve problems such as poor pasting of the adhesive sheet, and achieve the effect of easy peeling and pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described below with reference to the drawings.

[0030] In addition, in this specification, unless otherwise specified, terms such as "left", "right", "upper" and "lower" figure 1 as the benchmark.

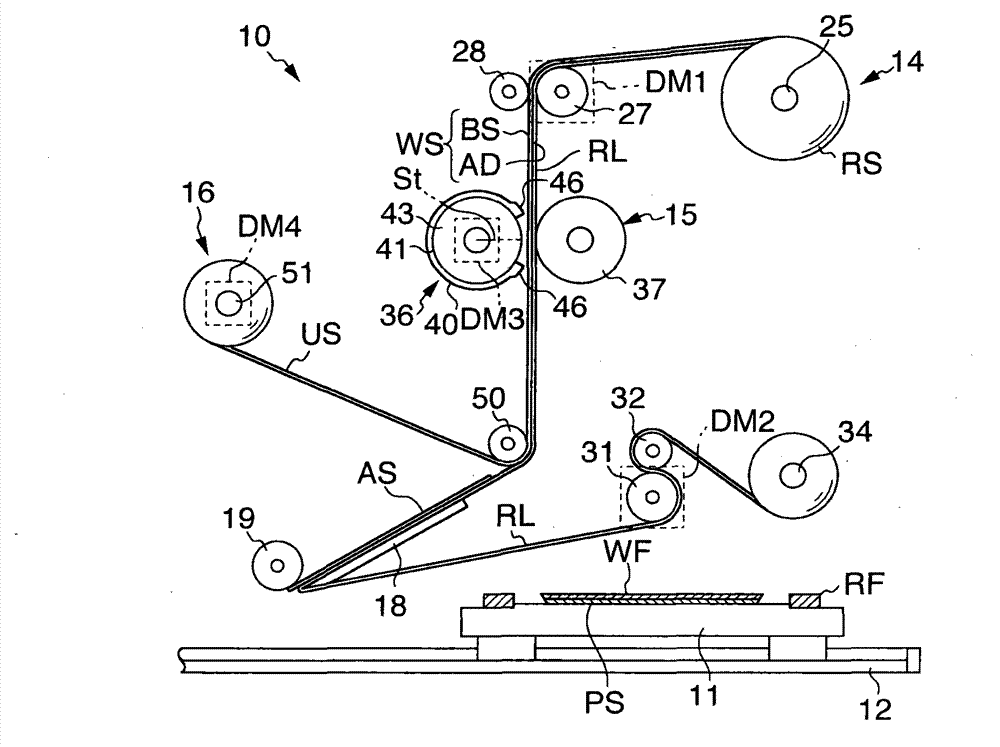

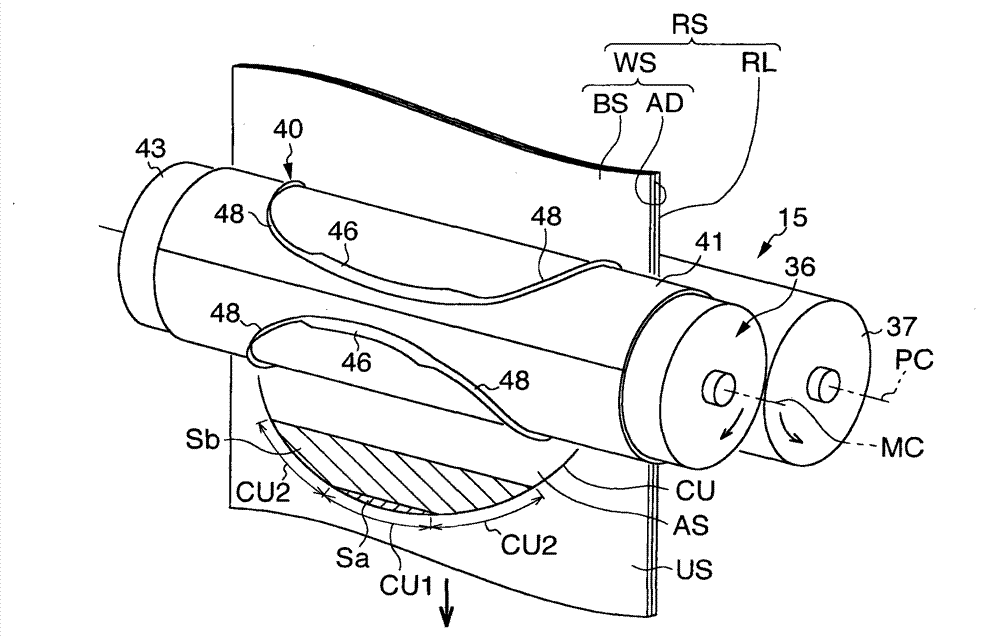

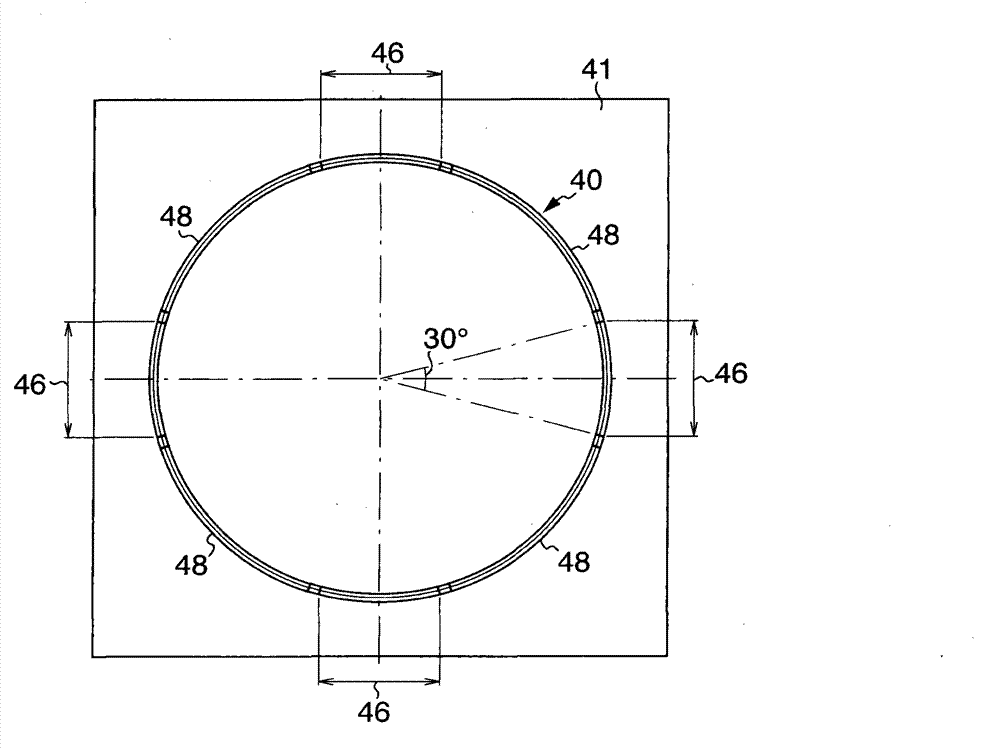

[0031] exist figure 13, the sheet sticking device 10 is configured to include: a table 11 that absorbs and supports the wafer WF and the ring frame RF as an adherend; Move up; Sending unit 14, can send out raw material roll RS, and raw material roll RS is made of strip-shaped sheet RL and the strip-shaped sheet WS temporarily pasted on one side of peeling sheet RL; A slit CU is formed on the strip-shaped sheet WS of the raw material roll RS sent out, an adhesive sheet AS is formed inside the slit CU, and a useless sheet US is formed outside the slit CU; the winding unit 16 can roll the useless sheet US The release plate 18 as a peeling unit folds back the release sheet RL, thereby peeling the adhesive sheet AS from the rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com