Grafting knife suitable for rootstock ends

A grafting knife and rootstock technology, applied in the field of rootstock end grafting knives, can solve problems such as reducing the grafting survival rate, grafting interface filming, grafting failure, etc., and achieves the effects of simple and integrated operation, stable and consistent depth, and prevention of operational errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

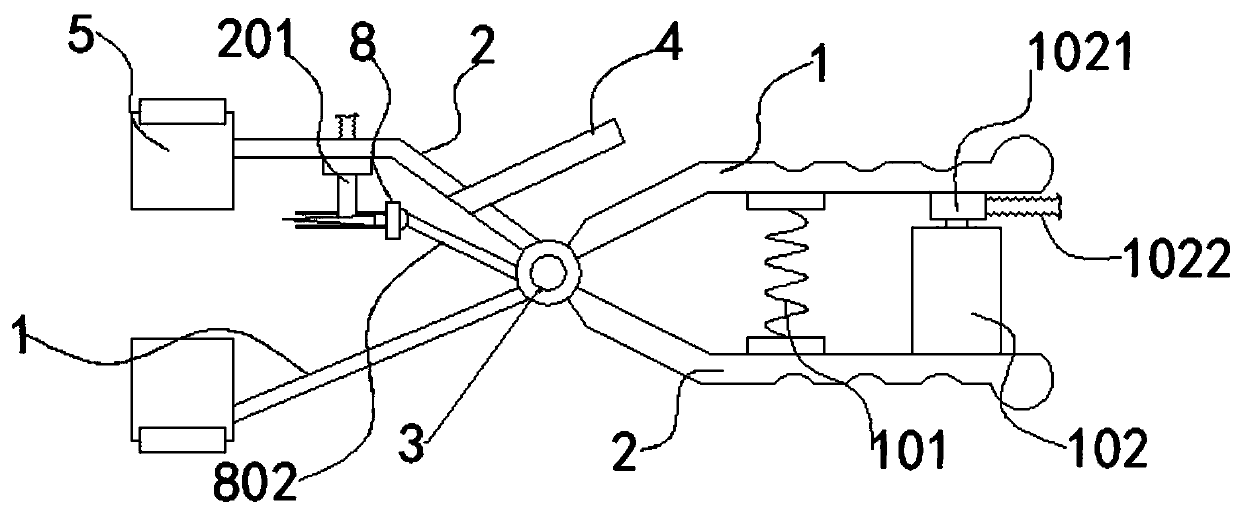

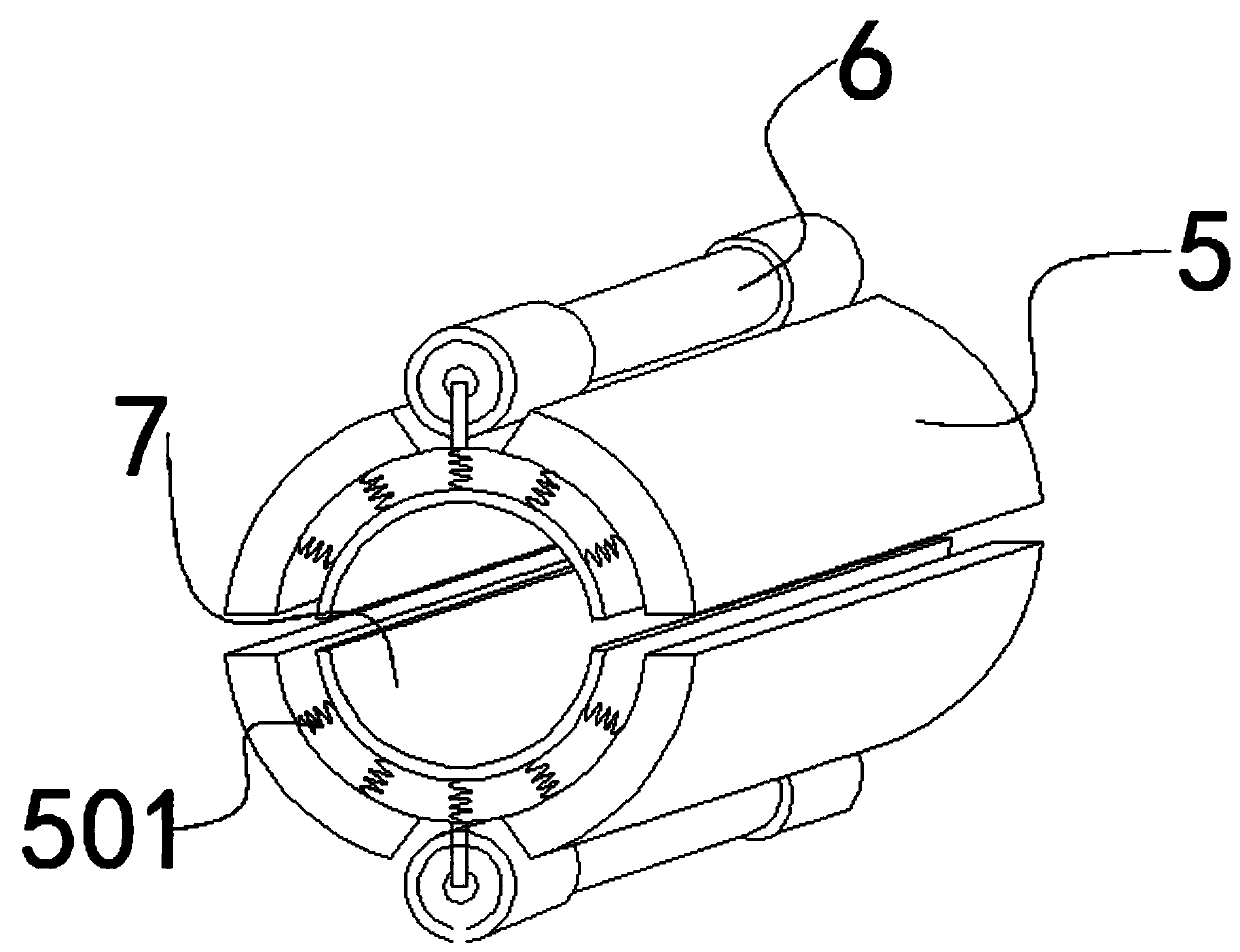

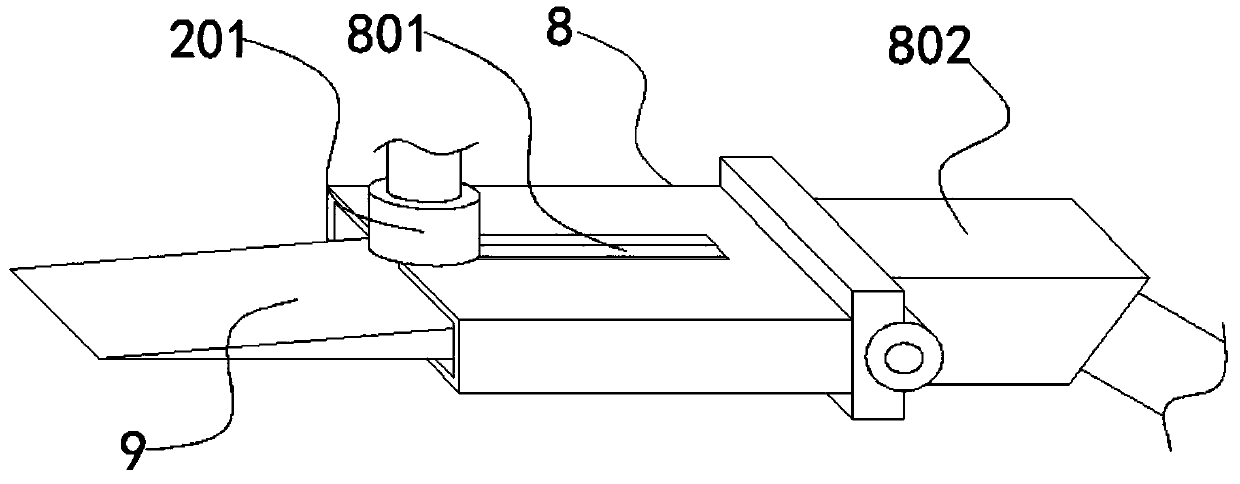

[0031] as attached figure 1 to attach Image 6 Shown:

[0032] The present invention provides a grafting knife suitable for rootstock ends, which includes a first cross arm 1, a second cross arm 2, a bearing shaft 3, a ladder groove 4, a wrapping plate 5, and a binding tape roll 6. Meniscus 7, truss 8, cutting knife 9, return spring 101, water storage chamber 102, push pump 1021, conduit 1022, pressure bearing rod 201, spring 501, chute 801, positioning rod 802 and water seepage port 901, A first cross arm 1 and a second cross arm 2 are connected to the outside of the bearing shaft 3 for common rotation, and a return spring 101 is fixedly connected between the first cross arm 1 and the second cross arm 2 on one side, and the second cross arm 2 on one side The upper part is fixedly connected with a water storage chamber 102, and the upper opening of the water storage chamber 102 is nested with a push-type pump 1021, and the outer opening of one side of the push-type pump 1021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com