Lead carbon super battery moisturizing maintenance method

A super battery, lead-carbon technology, applied in secondary battery repair/maintenance, secondary battery charging/discharging, etc., can solve the problems of unavailable battery capacity, slow diffusion speed, recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

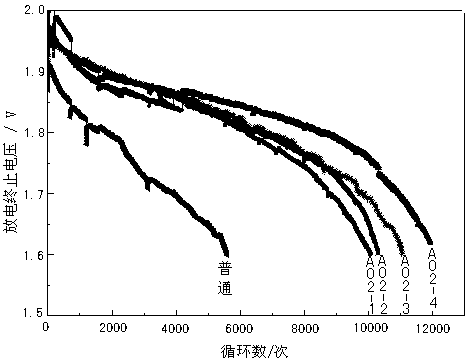

Embodiment 1

[0020] (1) The weight of the battery pack after dehydration is subtracted from the rated weight of the original battery pack, and then divided by the number of single cells in the battery pack to calculate the amount of water added to the single cell. The total water loss of the battery pack is 53 grams. The amount of water is 8.8 grams (53 grams / 6);

[0021] (2) Add deionized water to the single cell battery numbered A02-1 three times, and the water addition amount is 40%, 30%, and 30% of the water addition amount of the single cell battery (8.8 grams), and do not stand still after adding water each time. Charge according to the water replenishment test process, and remove the excess acid before charging. The water replenishment test process is to first charge the battery with a single cell voltage limit of 2.5V, 0.1 times the rated capacity of the 2-hour rate, and a constant current constant voltage charge for 16 hours, and then Charge with a constant current of 0.025 times ...

Embodiment 2

[0023] (1) The weight of the battery pack after dehydration is subtracted from the rated weight of the original battery pack, and then divided by the number of single cells in the battery pack to calculate the amount of water added to the single cell. The total water loss of the battery pack is 53 grams. The amount of water is 8.8 grams (53 grams / 6);

[0024] (2) Add deionized water to the single cell battery numbered A02-2 three times, the amount of water added is 50%, 30%, and 20% of the water added to the single cell battery (8.8 grams), and the standing time after each addition of water is respectively For 1h, 0.5h, 0h, charge according to the water replenishment test process, and remove the excess acid before charging. The water replenishment test process is to limit the voltage of the battery cell to 2.5V, and the current of 0.1 times the rated capacity of the 2-hour rate Charge at constant current and constant voltage for 18 hours, and then charge at a constant current ...

Embodiment 3

[0026] (1) The weight of the battery pack after dehydration is subtracted from the rated weight of the original battery pack, and then divided by the number of single cells in the battery pack to calculate the amount of water added to the single cell. The total water loss of the battery pack is 53 grams. The amount of water is 8.8 grams (53 grams / 6);

[0027] (2) Add deionized water to the single-cell battery numbered A02-3 three times. The amount of water added is 60%, 20%, and 20% of the water added to the single-cell battery (8.8 grams). The standing time after each addition of water is respectively For 2h, 1h, 0.5h, charge according to the water replenishment test process, and remove the excess acid before charging. The water replenishment test process is to limit the battery cell voltage to 2.5V, 0.1 times the rated capacity of the 2-hour rate current Charge at constant current and constant voltage for 19 hours, and then charge at a constant current of 0.025 times the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com