Tungsten-based material super battery and super capacitor

A super battery, tungsten-based technology, applied in the field of chemistry, can solve problems that cannot meet the needs of large-scale energy storage and power supply fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] First, the synthesis method and specific characterization of tungsten oxide are as follows:

[0137] (1) Preparation of tungsten oxide.

[0138] (A) Ammonium tungstate was dissolved in deionized water to prepare a 3% ammonium tungstate solution by mass fraction, and 2 molar concentration of sulfuric acid was added to adjust the acid concentration in the solution to 1.5%. Stir the above solution for 30 minutes to obtain a uniformly mixed solution, transfer the mixed solution to a 5-liter reactor and heat to 95 degrees Celsius for 60 hours; after the reaction is completed, it is naturally cooled, the product is washed with deionized water, and the electrode is obtained after drying. Tungsten oxide active material. In order to further understand the morphology and structure of the prepared hydrated tungsten oxide material, the applicant further performed transmission electron microscope and XRD characterizations on it, and the results are as follows:

[0139] attached ...

Embodiment 2

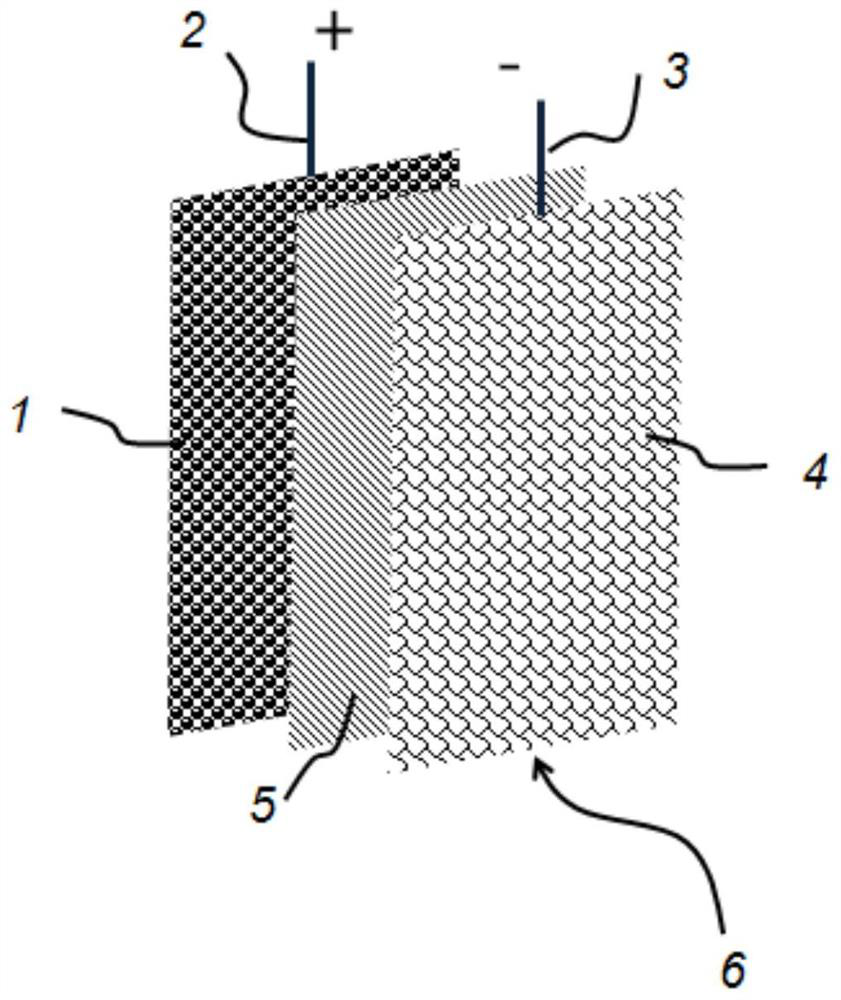

[0153] Example 2 Tungsten super battery based on tungsten oxide negative electrode and carbon positive electrode

[0154] (1) Preparation of tungsten oxide. Dissolve ammonium tungstate in deionized water to prepare a 5% ammonium tungstate solution by mass fraction, add 2 molar sulfuric acid to adjust the acid concentration in the solution to 1.5%, and then add 1% ammonium sulfate by mass fraction. Stir the above solution for 30 minutes to obtain a uniformly mixed solution, transfer the mixed solution to a reaction kettle and heat it to 90 degrees Celsius for 12 hours; after the reaction is completed, cool naturally, wash the product with deionized water, and obtain a hexagonal crystal structure after drying. Tungsten active material.

[0155] (2) Fabrication of tungsten oxide electrodes and carbon electrodes. The tungsten oxide prepared by the method (1) in Example 2, the carbon black conductive agent, and the polyvinylidene fluoride binder are dispersed in an appropriate amou...

Embodiment 3

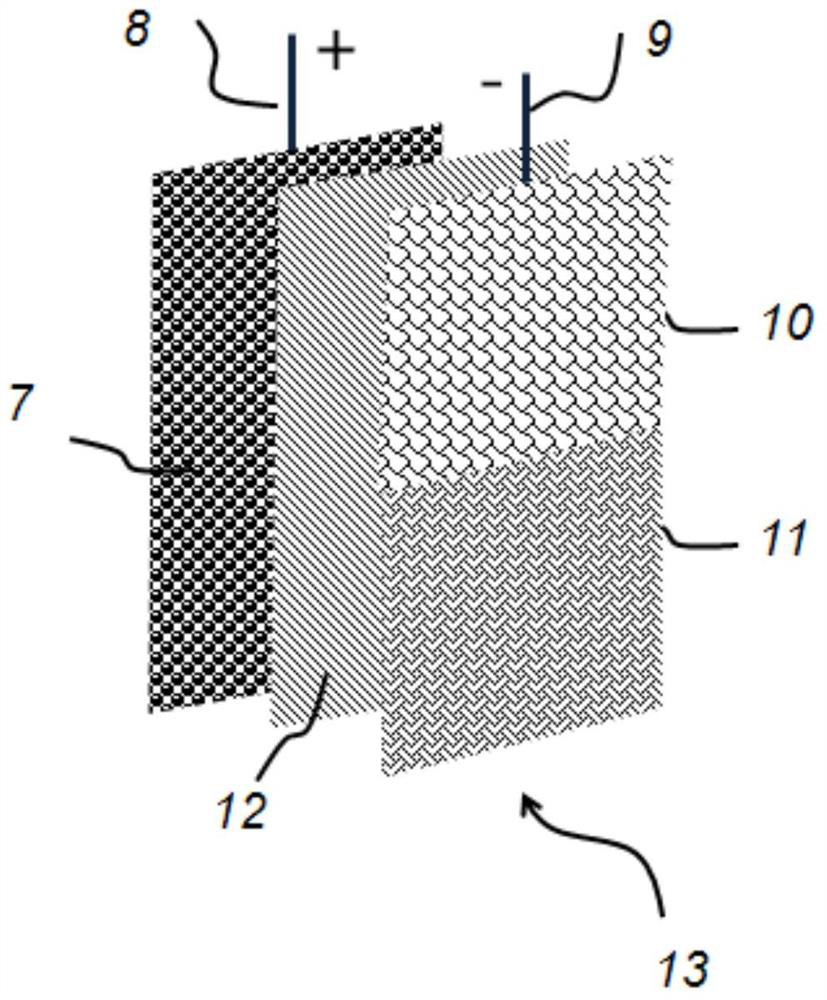

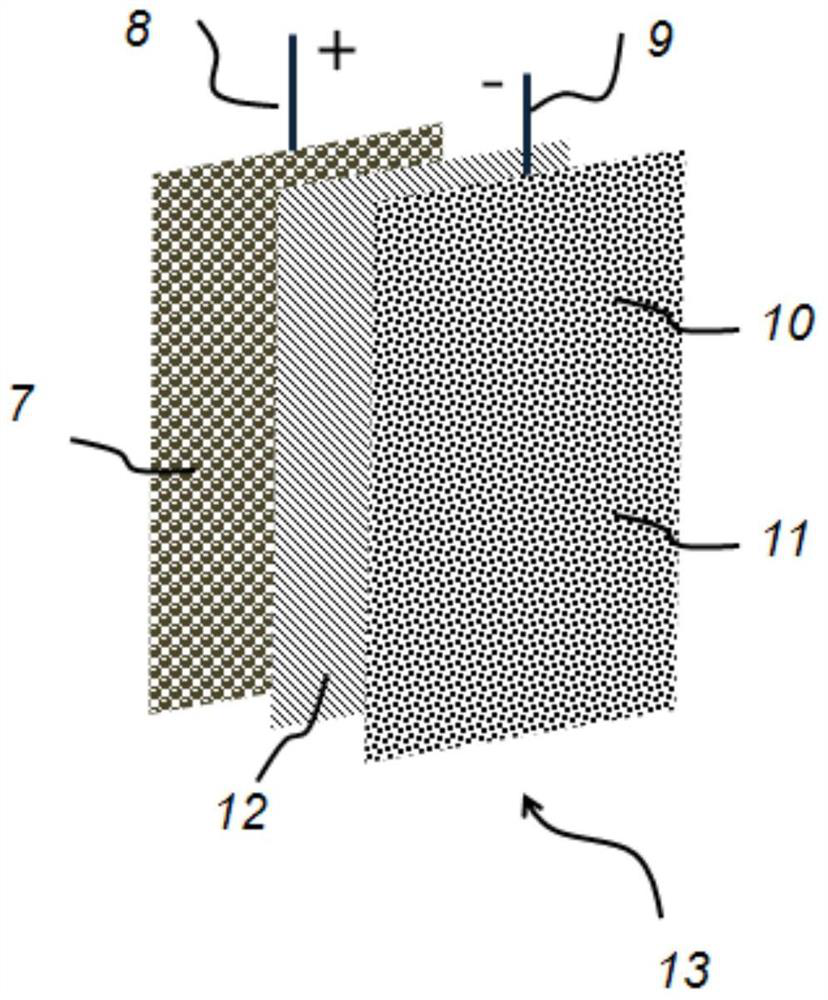

[0159] Example 3 Tungsten super battery based on carbon-tungsten composite negative electrode and carbon positive electrode

[0160] (1) Fabrication of composite tungsten oxide electrode and carbon electrode.

[0161] The tungsten oxide active material synthesized as in Example 2 was used. Disperse the tungsten oxide, activated carbon, carbon black conductive agent, and polyvinylidene fluoride binder in an appropriate amount in the ratio of 4:4:1:1 in the nitrogen methyl pyrrolidone solvent, stir and mix evenly to obtain a composite tungsten oxide electrode slurry. It should be noted here that the carbon material in the composite tungsten oxide electrode can be any commercially available carbon material used in the electrode, and activated carbon is only one of the commonly used options, rather than any particularly preferred example. Those skilled in the art can easily select other common carbon materials to replace the activated carbon in this embodiment. In each of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com