Accurate cleaning mechanism of intelligent electric automatic cleaning robot

A cleaning mechanism and automatic cleaning technology, which is applied to cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as trouble, low cleaning efficiency, and low cleaning efficiency, and improve cleaning efficiency. , Improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

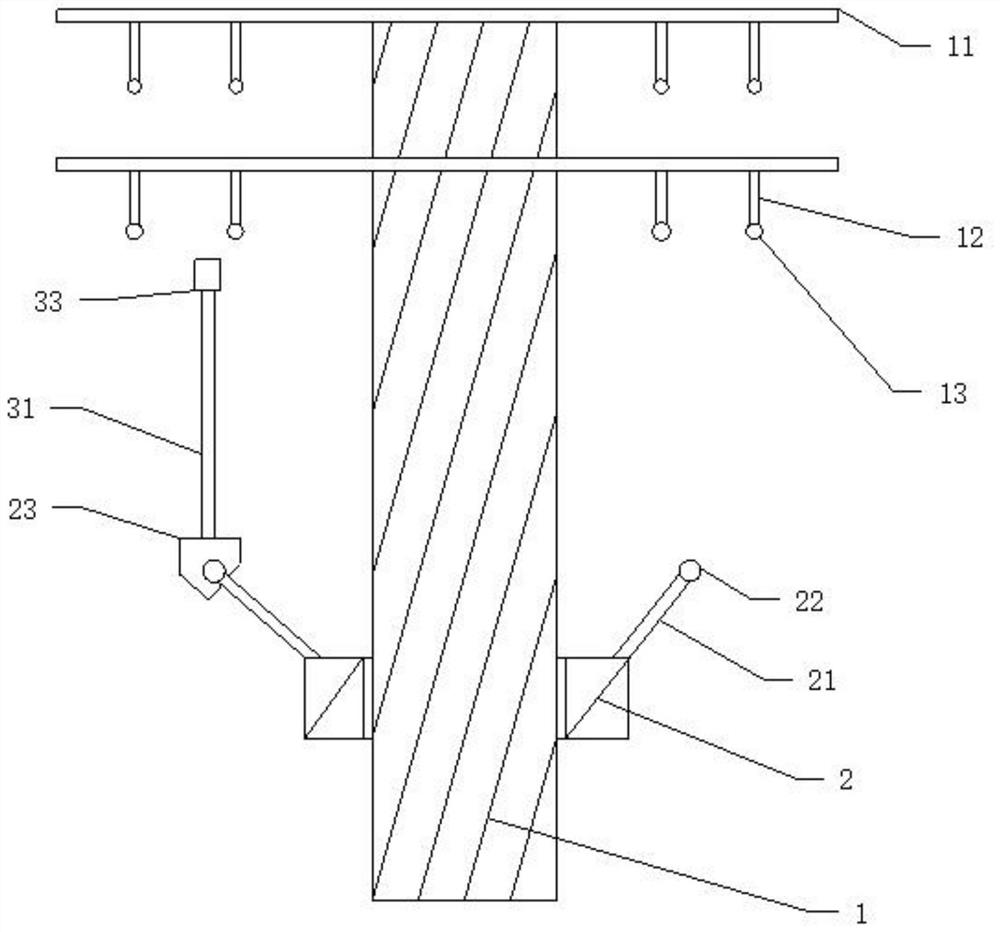

[0054] Such as Figure 1 to Figure 11 As shown, a precision cleaning mechanism of an intelligent electric automatic cleaning robot includes a utility pole 1, a cable support rod 11 is arranged on the utility pole 1, an insulating column 12 is arranged on the cable support lever 11, and an insulating column 12 is arranged on the insulating column 12. A cable 13 is arranged, and a lifting control mechanism and a precision cleaning mechanism 3 are also included.

[0055] Lifting and sliding on the utility pole can be realized through the lifting control mechanism, and precise cleaning operation can be performed on the insulating column on the utility pole through the precision cleaning mechanism 3 .

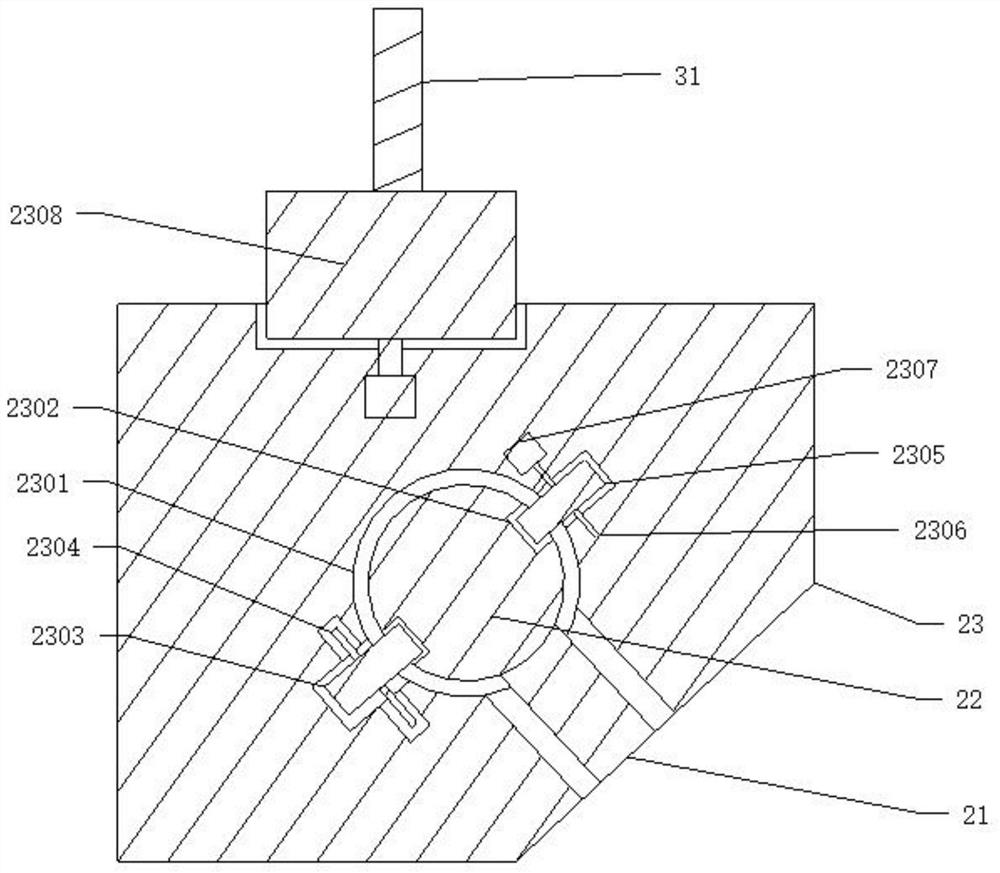

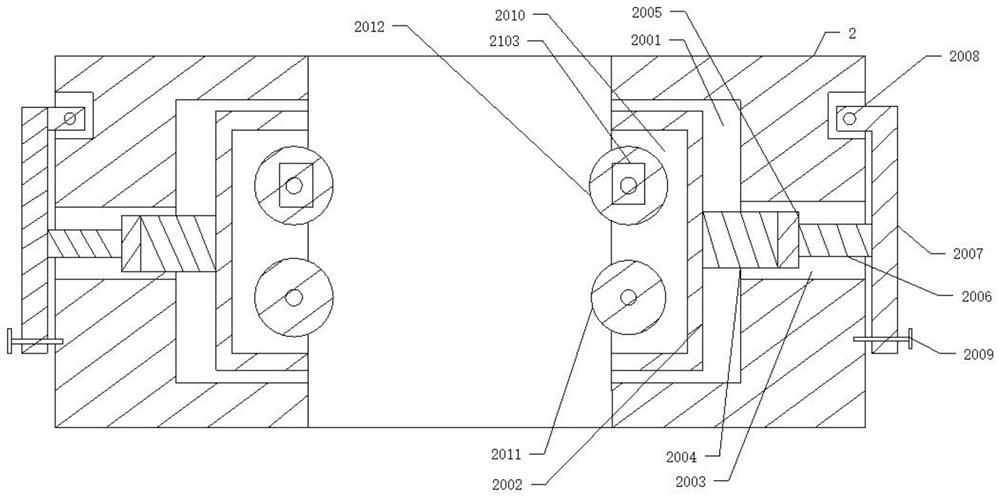

[0056] The lifting control mechanism includes a lifting module 2 and a rotating mechanism 3. The lifting module 2 is provided with two, and the lifting module 2 has a supporting slideway 22 respectively. The lifting module 2 is respectively provided with The rotating driving wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com