A Simple Fixture for Conduit Galvanized

A conduit, a simple technology, applied in the field of fixtures with galvanized inner and outer surfaces of conduits, can solve the problems of electric shock, poor contact, inconvenient clamping and other problems of the operator, and achieve the effect of convenient clamping, good conductivity, and easy installation and hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

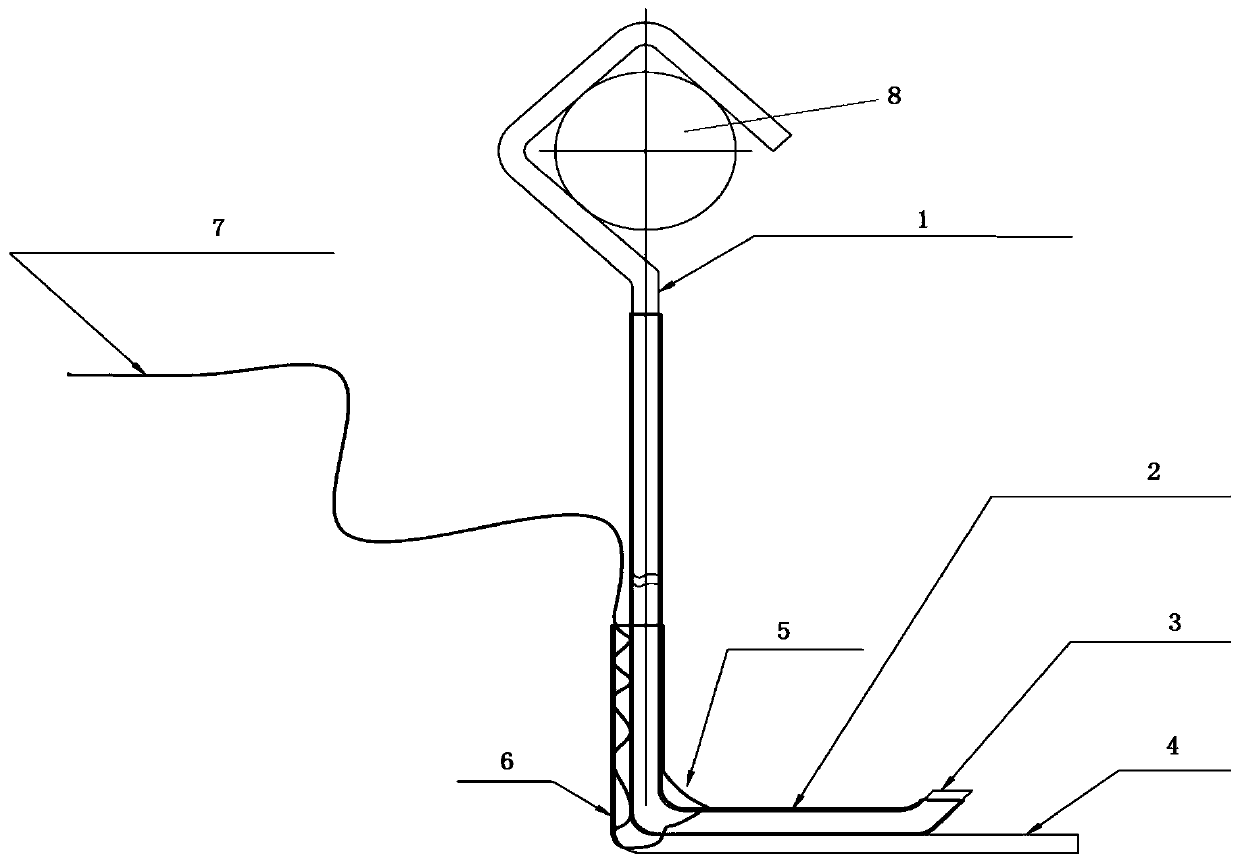

[0026] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

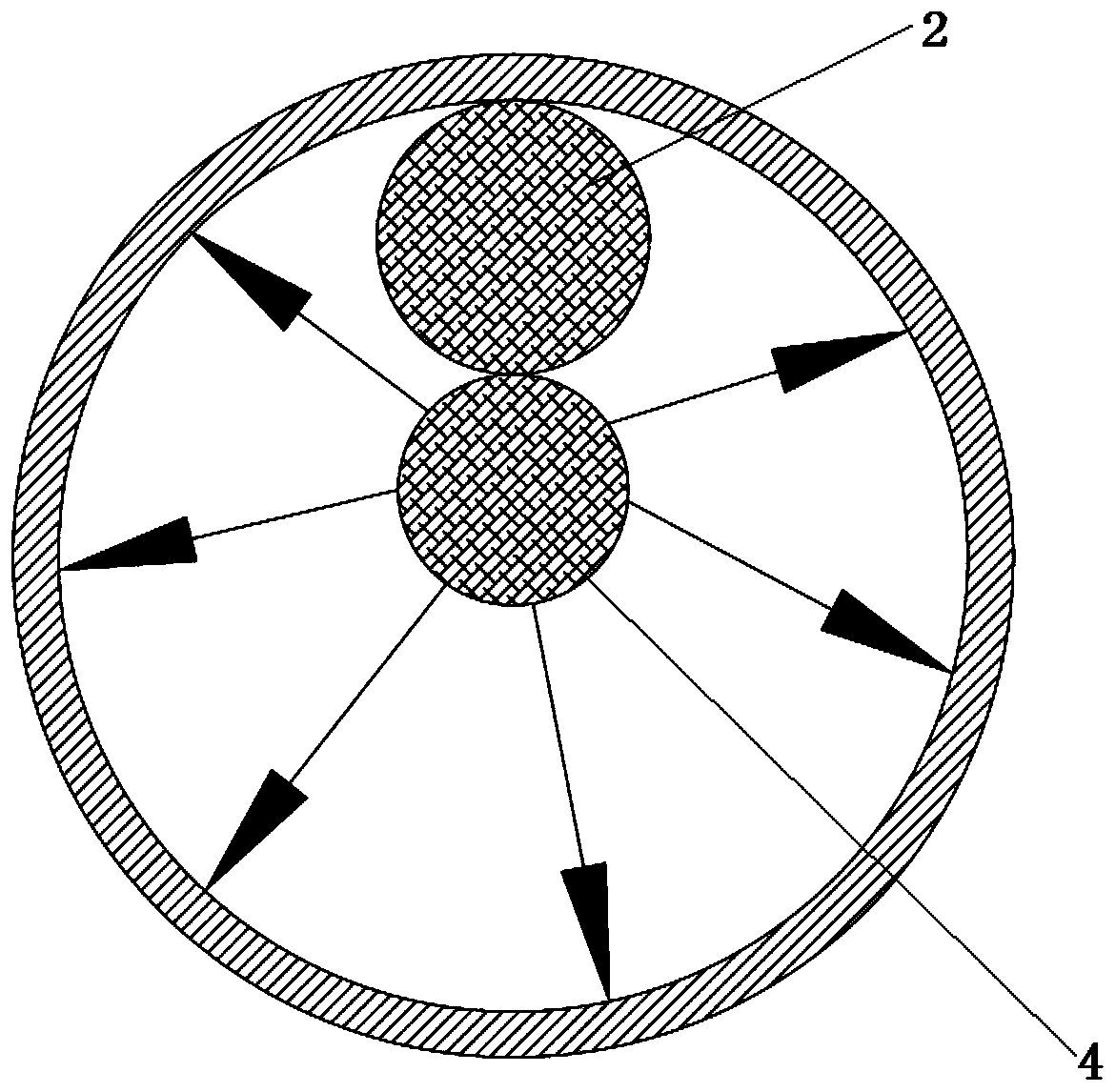

[0027] Such as Figure 2~4 As shown, it is a simple fixture of the present invention, including a copper wire as the first lead, which is connected to the cathode rod 8, and a copper wire as the second lead 2 is connected to the anode rod 9, and the copper wire is connected to the auxiliary anode lead Winding connection, the auxiliary anode wire and the second wire are combined with the first wire wrapped with the first insulating layer (through image 3 The second insulating layer 6 is wrapped with insulating tape in this example).

[0028] (1) Material selection:

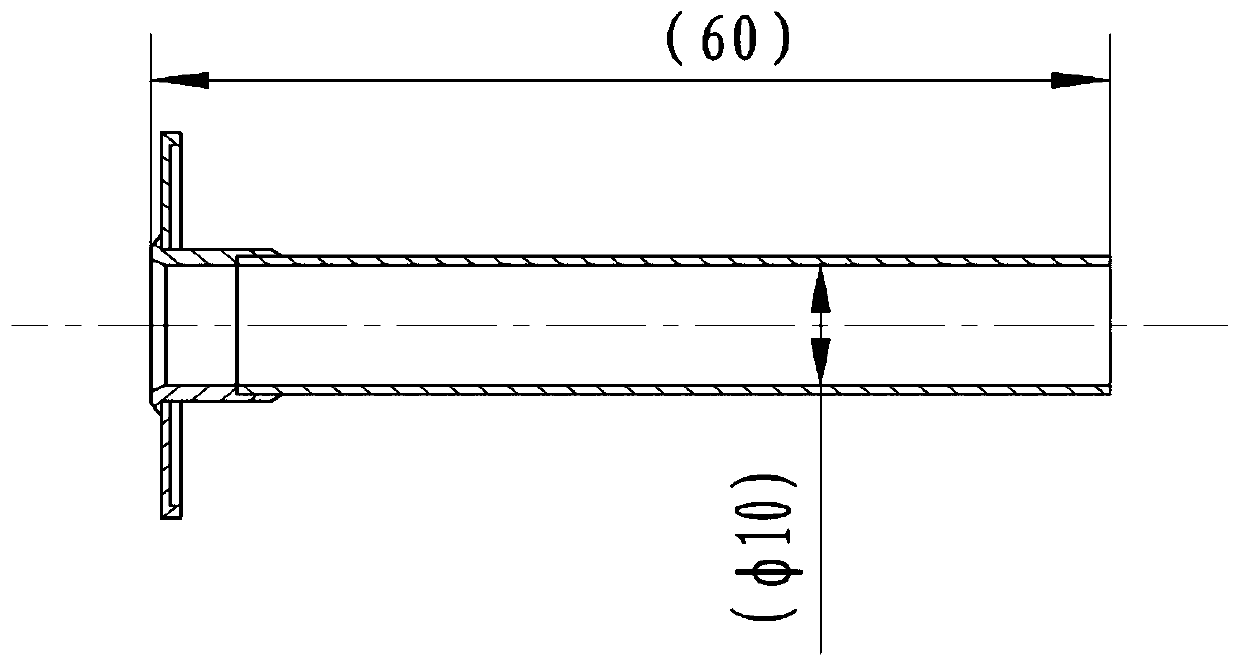

[0029] Choose Φ3mm copper wire as the first wire, and the hook section 1 of the first wire is used as the hook connecting the parts to the cathode rod 8; use Φ2.5mm stainless steel wire as the auxiliary anode wire; choose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com