Preparation method of electrochemically active material

An active material, electrochemical technology, applied in the field of preparation of electrochemical active materials, can solve the problems of increasing the resistance of the material, reducing the conductivity, affecting the purity, etc., so as to solve the problem of conductivity and realize the effect of continuous production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment prepares nano-Li 5 FeO 4 / CNT electrochemically active material process is as follows:

[0034] S 1 120g LiOH, 186g ferrocene, 1800g benzyl alcohol, 400mL methanol and 60mL thiophene were mixed uniformly in a closed glass reactor, and transported to a vertical cyclone furnace with a temperature of 1050°C at a rate of 20mL / s. The reaction is carried out under protection to obtain a Li-Fe-O / CNT nanoscale precursor;

[0035] S 2 , put the Li-Fe-O / CNT nanoscale precursor into a rotary furnace, introduce a pure oxygen atmosphere, raise it to 500 ° C, keep it for 2 hours, and then cool it down to room temperature to obtain high-purity Li 5 FeO 4 / CNT electrochemically active materials.

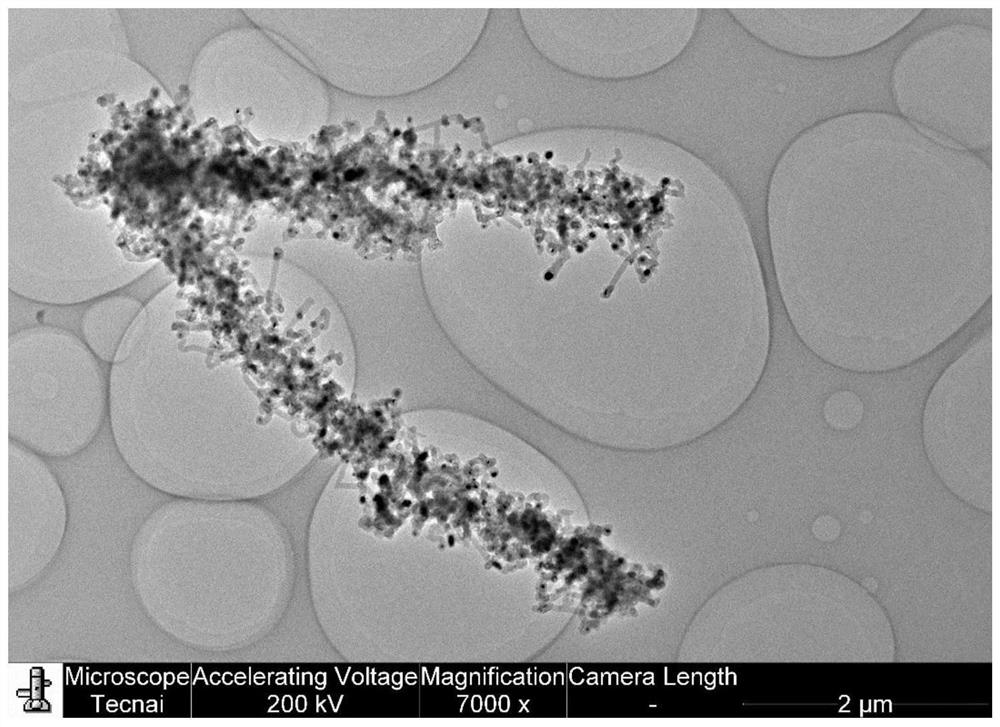

[0036] Li obtained in this example 5 FeO 4 / TEM images of CNTs electrochemically active materials as figure 1 As shown, the crystal grains are 20-50 nanometers; the material volume resistance is 275mΩ cm and the lithium ion capacity is 703mAh / gLi. 5 FeO 4 ;

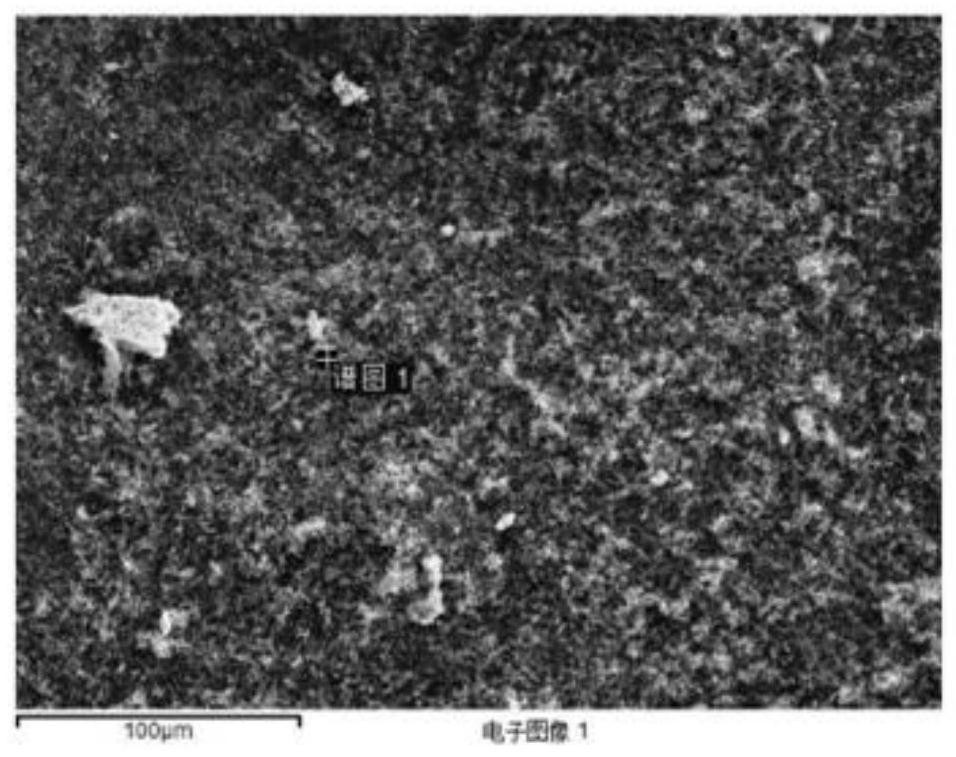

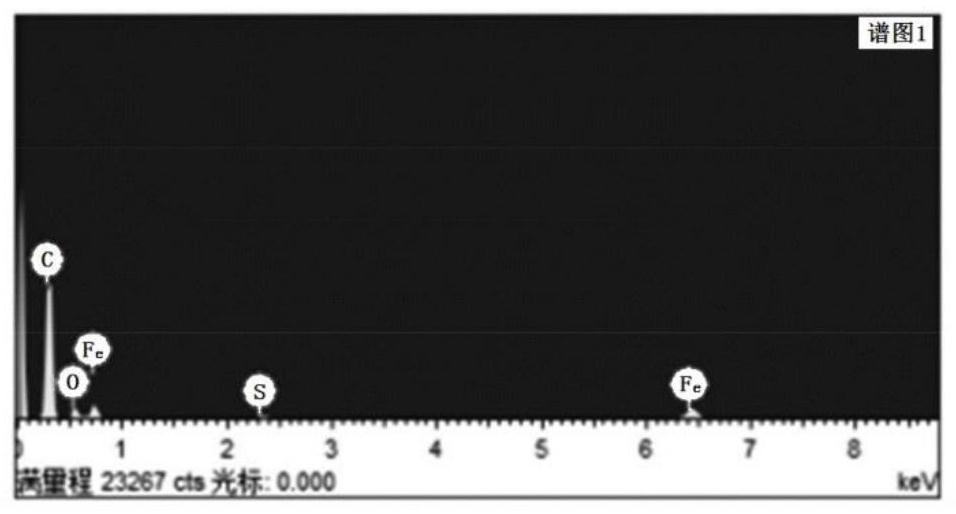

[003...

Embodiment 2

[0039] This embodiment prepares nano-Li 5 FeO 4 / CNT electrochemically active material process is as follows:

[0040] S 1 , mix 330g of lithium acetate, 186g of ferrocene, 1.7L of benzyl alcohol, 300mL of methanol and 60mL of thiophene in a closed glass reactor, and transport them to a vertical cyclone furnace with a temperature of 850°C at a rate of 25mL / s. , react under the protection of nitrogen to obtain the nanoscale Li-Fe-O / CNT precursor;

[0041] S 2 , the nanoscale Li-Fe-O / CNT precursor was added to the rotary furnace, and the CO2-free 2 in dry air, heated to 500°C, kept for 2 hours, and then cooled to room temperature to obtain Li 5 FeO 4 / CNT electrochemically active materials.

[0042] The nanometer Li that present embodiment makes 5 FeO 4 / CNT electrochemically active material, its TEM picture is as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com