Novel conveying belt corrosion resistant and impact resistant anti-tear embedded coil

A conveyor belt and corrosion-resistant technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems that the detection device cannot detect the induction signal, the resistance value of the closed coil is small, and the use requirements cannot be met. Achieve the effect of improved tensile strength, strength impact resistance and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

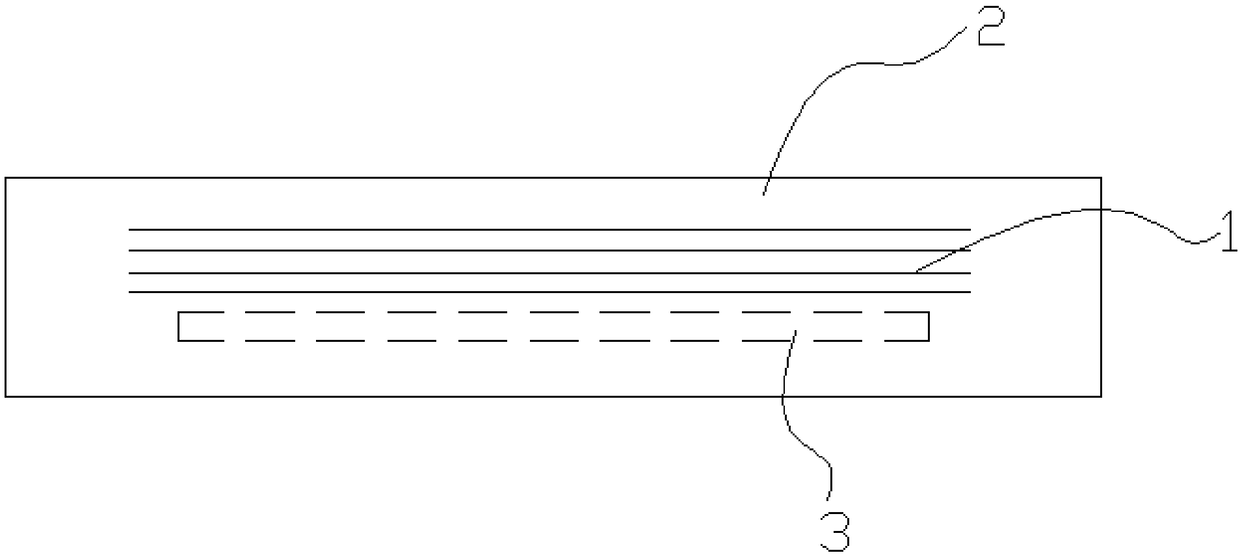

Image

Examples

Embodiment Construction

[0019] The pre-embedded coil of the present invention is made of stainless steel wire, and the diameter of the stainless steel wire is 0.05-1.5 mm, preferably 0.1 mm. There is a layer of conductive coating on the surface of the stainless steel wire, and the conductive coating is preferably a copper coating, a zinc coating, a tin coating or a silver coating. Compared with the existing brass-plated steel wire, the stainless steel wire has good corrosion resistance, high strength and impact resistance, but due to its high resistance, the electromagnetic induction signal cannot be detected, so the surface is coated with a conductive coating.

[0020] The coil structure of the present invention can also be formed by plying a single stainless steel wire to form stainless steel cords with specifications such as 1*7, 1*19, 7*7, 7*19 or 3*4, and the diameter of the cord is 0.5-2mm. The stainless steel curtain The wire is made into a spiral shape, a flat spiral shape or a sine wave shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com