Copper supporting piece, preparation method thereof and electrical assembly

A support, pure copper technology, applied in the direction of electrical components, circuits, electric switches, etc., can solve the problems of reducing the service life of electrical appliances, affecting the service life of electric arcs, preventing virtual welding or over welding, and improving melting inconsistencies , Excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

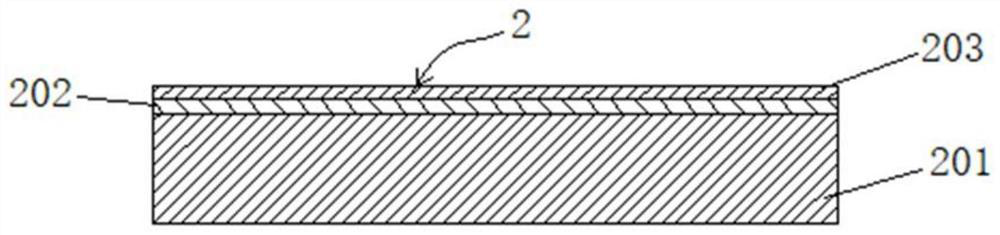

[0048] In some preferred embodiments, in the above method for preparing a copper support, after punching the heat-treated layered composite tape, the method may further include: punching the first metal layer, and forming a through hole in the first metal layer The layered composite material has through-holes in the thickness direction for exhaust and slag removal in the welding center area. Further, a concave guide groove can be processed on the outer surface of the second metal layer near the through hole, so as to guide the excess solder at the welding surface to the two ends of the copper support.

[0049] In some preferred embodiments, in the preparation method of the copper support, the obtained layered composite tape is heat-treated, wherein the temperature is 300°C to 800°C, the time is 2 hours to 6 hours, and the atmosphere is H 2 , N 2 or ammonia decomposition atmosphere.

[0050] Based on the structural features of the copper support in the above embodiment, in an...

Embodiment 1

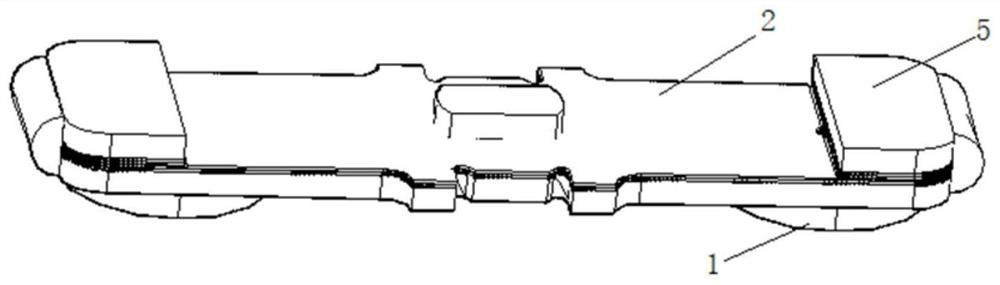

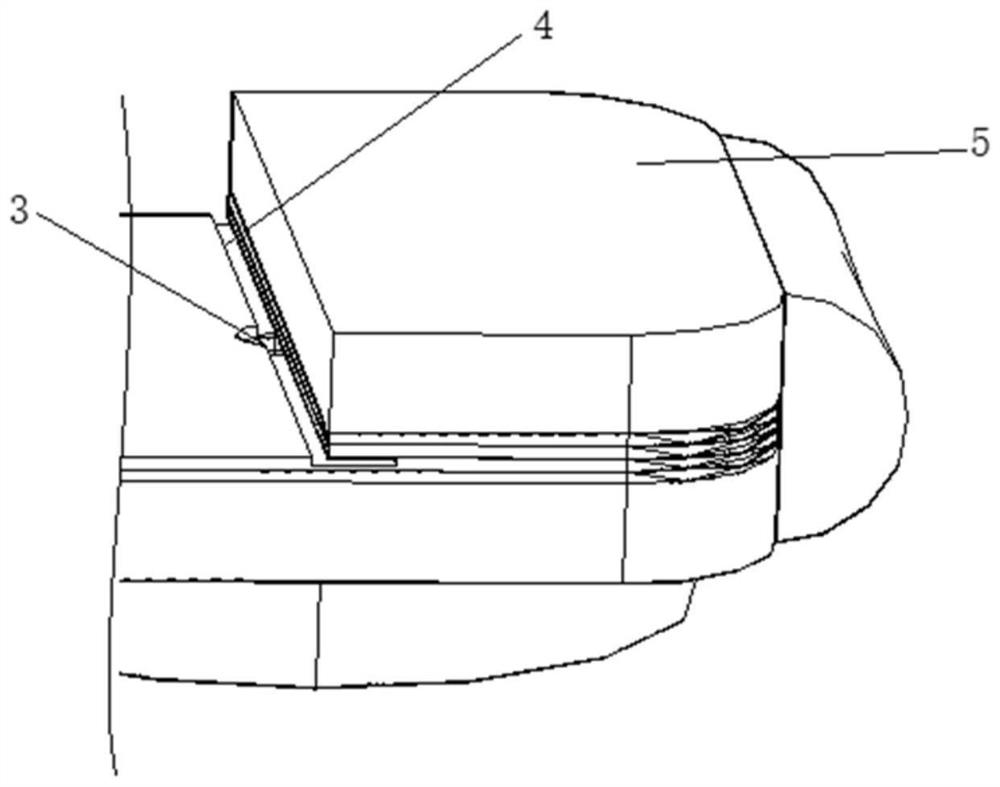

[0053] refer to figure 2 , image 3 As shown, it is a schematic diagram of the structure of the electrical component, which includes: an electrical contact 1 and a copper support, wherein the electrical contact 1 is made of AgSnO2 material; the copper support is such as figure 1 As shown, it includes a first metal layer, an intermediate metal layer and a second metal layer. In this embodiment, the first metal layer and the second metal layer are all made of pure copper, and the intermediate metal layer is pure iron, that is, the copper support is made of Cu / Fe / Cu layered composite tape.

[0054] The preparation method of the electrical component includes the following steps:

[0055] S1: Stack pure Cu strips, pure Fe strips, and pure Cu strips in sequence, and perform asymmetric cold rolling to obtain Cu / Fe / Cu strips. In the Cu / Fe / Cu strips, the intermediate layer is an intermediate metal. The thickness of one outer Cu layer is 80% of the whole strip, and the thickness of...

Embodiment 2

[0060] refer to Figure 4 , Figure 5 As shown, it is a schematic diagram of the structure of the electrical component, which includes an electrical contact 1 and a copper support, wherein the electrical contact 1 is made of AgNi10 material; the copper piece 2 is made of Cu / Fe / Cu layered composite tape material, the first The metal layer adopts red copper strip, the middle metal layer adopts low carbon steel strip, and the second metal layer adopts Cu / H65 composite copper material.

[0061] In this embodiment, the preparation method of the electrical component includes the following steps:

[0062] S100: Stack the red copper strip, the low-carbon steel strip, and the Cu / H65 composite copper material in sequence, perform asymmetric cold-rolling and compounding to obtain a layered composite strip, and heat treatment again. In the layered composite strip, the middle metal layer is low carbon steel, the thickness of one outer copper strip is 30% of the whole strip, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com