Continuous-electroplating liquid conduction apparatus and continuous liquid electroplating method

A conductive device and liquid technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve problems such as electroplating surface damage, achieve the effect of improving quality, simple structure, and solving conductive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

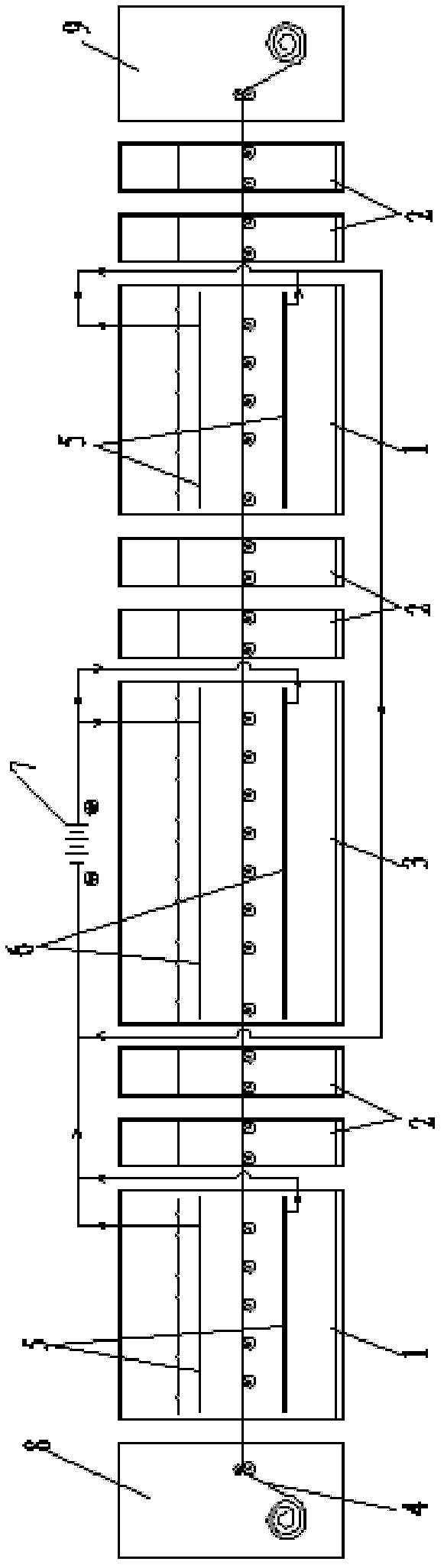

[0018] Such as figure 1 As shown, a continuous electroplating liquid conductive device includes a feeding mechanism 8, a conductive tank 1, a water washing tank 2, an electroplating tank 3, a water washing tank 2, a conductive tank 1, a water washing tank 2 and a feeding mechanism 9 arranged in sequence, And a continuous electroplating line is formed between the above-mentioned components, and the parts to be plated 4 (such as PCB boards) are sent to the unloading mechanism after being electroplated through the above-mentioned tanks successively from the feeding mechanism. Two first pole plates 5 are respectively arranged in each of the above-mentioned conductive tank bodies, and the two first pole plates are distributed near the opposite side walls of the conductive tank body, parallel to the continuous electroplating line, and separated on both sides of the part to be plated. Also be provided with two second pole plates 6 in above-mentioned electroplating tank tank body, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com