Movable silicon carbide smelting furnace

A technology of silicon carbide and smelting furnaces, applied in the field of movable silicon carbide smelting furnaces, which can solve problems such as difficulty in opening and closing, difficulty in ensuring dimensional stability, and easy deformation due to heat, and achieves the effect of reducing eddy currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

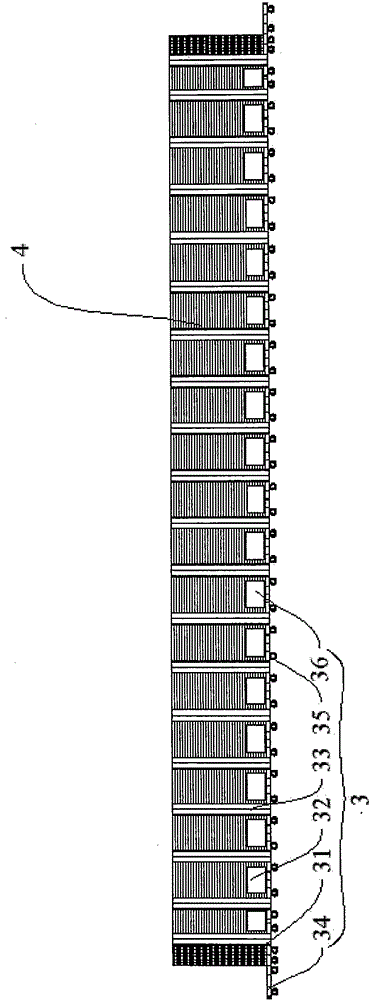

[0036] Such as Figure 3 ~ Figure 13 As shown, a movable silicon carbide smelting furnace includes: a furnace car 3, a gas collecting tank 1, and a track 2; The upper tank wall of 1 is connected with an exhaust pipe; the track 2 is laid along the length direction of the gas collecting tank 1 from the closed end of the gas collecting tank 1 and extends to the outside of the gas collecting tank 1, and the furnace car 3 enters and exits the gas collecting tank 1 along the track 2, The furnace car 3 is a movable silicon carbide smelting furnace.

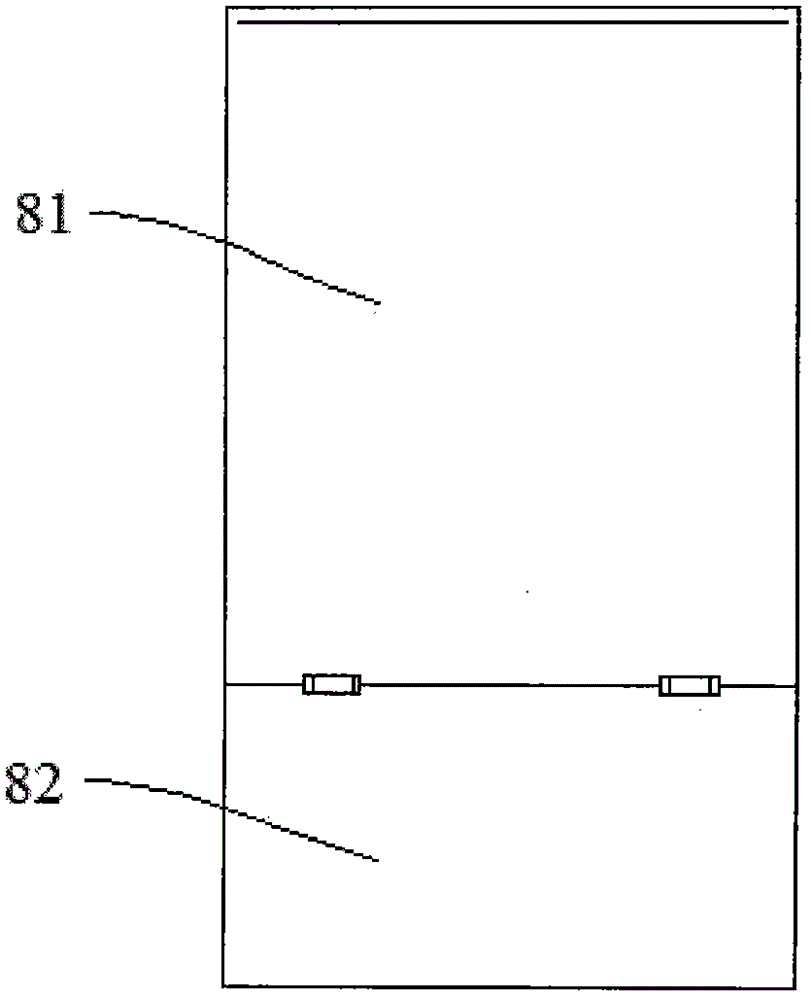

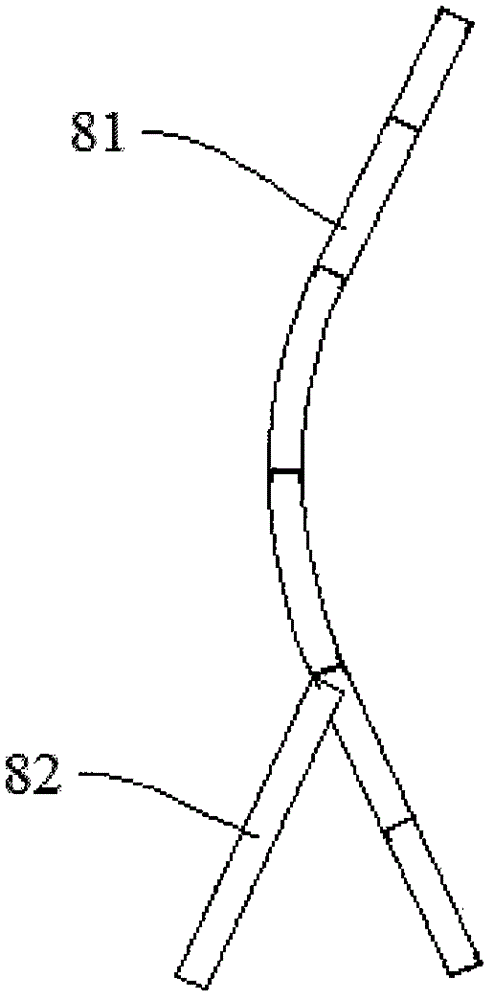

[0037] The furnace car 3 comprises: an end wall 31, a side wall 32, a side beam 33, a furnace car chassis 34, a sliding panel door 36, electrodes, and wheels 35; wherein the furnace car chassis 34 is a rectangular plate structure, and the furnace car chassis 34 A row of side beams 33 are fixed at intervals along the longitudinal direction, and the bottom 331 of the side beams is fixed on the chassis 34 of the furnace car. 34 at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com