Tool for turning excircle of transmission shaft universal joint fork and method for positioning and centering universal joint fork

A universal joint fork, car outer circle technology, applied in positioning devices, manufacturing tools, auxiliary devices, etc., can solve the problems of reduced accuracy of subsequent processes, incorrect blank clamping, large positioning rough reference error, etc., and achieve the top pressing operation. Simple and convenient, improve work efficiency, good centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

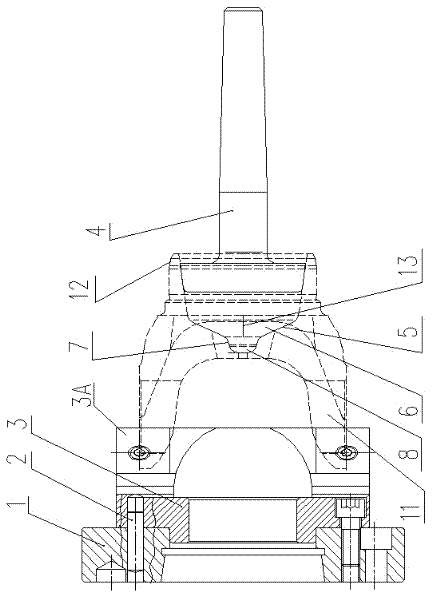

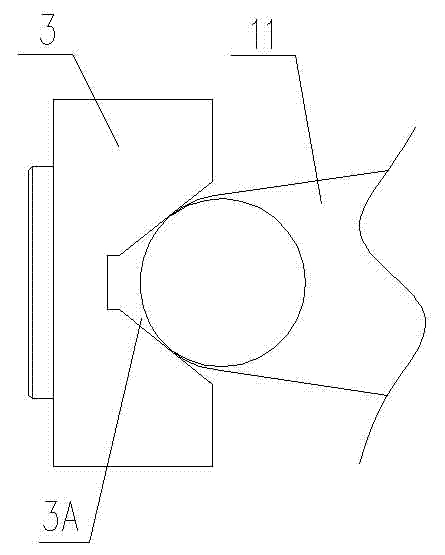

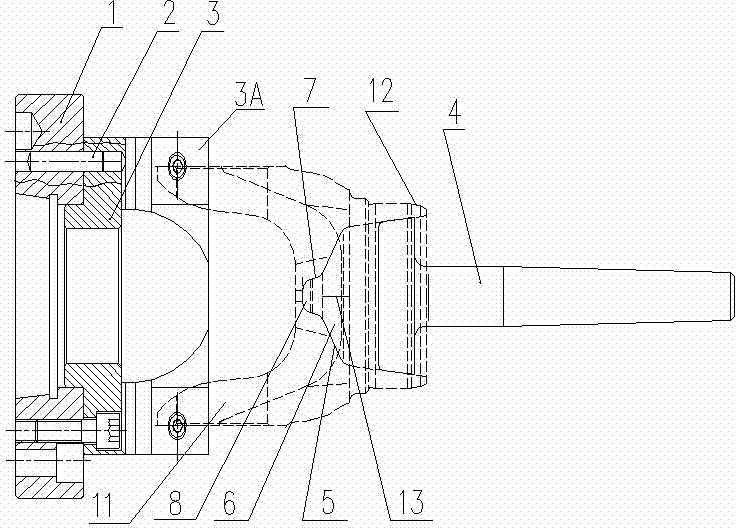

[0016] Such as figure 1 and figure 2 As shown, the outer circle tooling of the transmission shaft universal joint forklift of the present invention includes a connecting flange 1 and a tailstock top 4 installed on an external machine tool. The connecting flange 1 is connected with a V-shaped block 3 through a positioning pin 2, and the V-shaped The block 3 is provided with a V-shaped groove 3A for press-fitting with the two ears 11 of the universal joint yoke; The centering part 6, the center of the centering part 6 is protrudingly provided with the pressing top 8 which matches the central socket 7 of the universal joint fork.

[0017] The side wall of the centering portion 6 is provided with three ribs 13 by turning along the axial direction of the tailstock top 4 to form a triangular centering portion 6, and the three ribs 13 are connected with the inner socket of the universal joint fork. 5-phase fit. The three ribs 13 mentioned herein are preferably evenly arranged alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com