Horizontal type planet powerful spinning machine with four spinning rollers

A technology of powerful spinning and four-wheel spinning, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of good forming effect, equipment damage, large moment of inertia and centrifugal force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

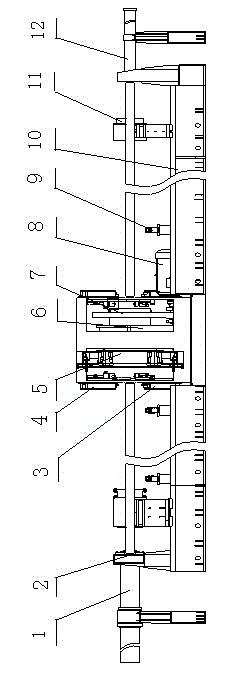

[0009] Referring to the accompanying drawings, a horizontal planetary four-wheel spinning machine includes a main motion oil cylinder 1, a main motion slider 2, a front and rear center frame 3, a material return device 4, a planetary four-wheel spinning device 5, and a supporting bearing seat 6. Transmission device 7, main motor 8, support frame 9, bed 10, tail top device 11, tail top oil cylinder 12, main motion oil cylinder 1 is connected with main motion slider 2, front and rear center frames 3, material return device 4 and The planetary four-wheel spinning device 5 is connected, the support bearing seat 6 is connected with the transmission device 7, and installed on the bed 10, the transmission device 7 is connected with the main motor 8, and installed on the bed 10, and the support frame 9 is installed on the bed On the body 10, the tail top device 11 is connected with the tail top oil cylinder 12. The working principle of the device is that the planetary four-wheel spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com