Thin-walled part slider type vehicle clamp

A slider-type, lathe fixture technology, applied in clamping, clamping devices, manufacturing tools, etc., can solve problems such as insufficient lathe clamping range and difficult automatic adjustment of fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

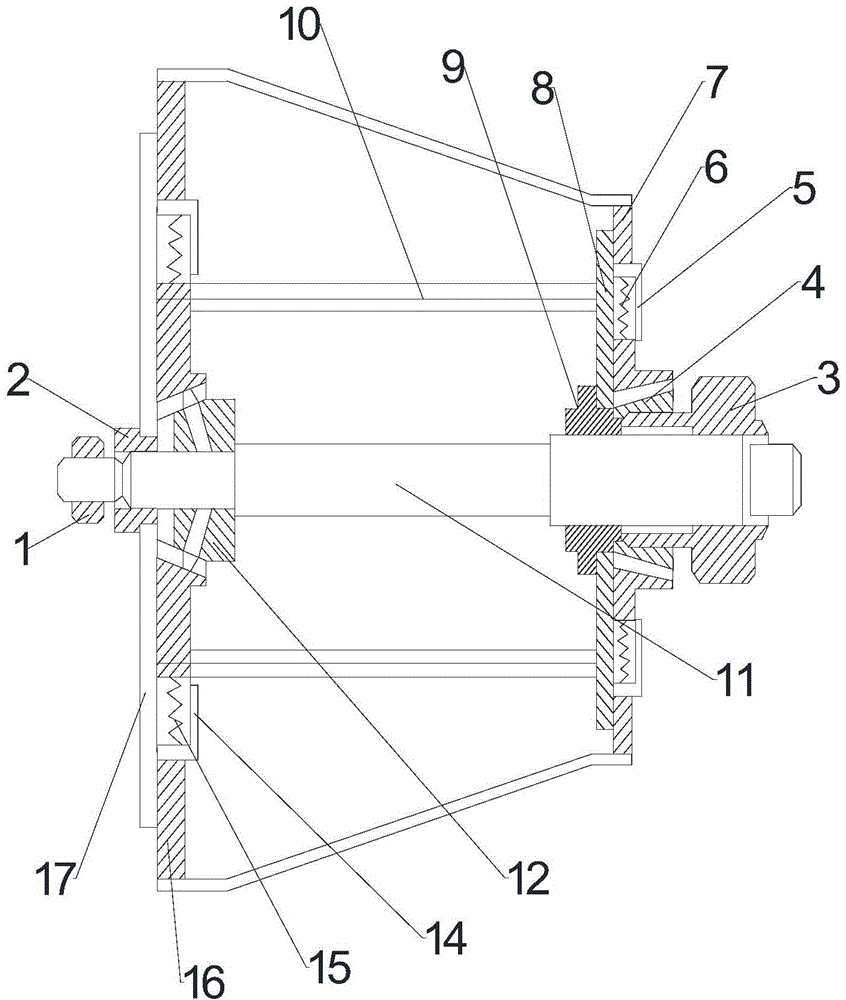

[0011] Depend on figure 1 It can be seen that the thin-walled slider type car fixture of the present invention includes a left nut 1, a right nut 3, a right cone 4, a right guide plate 5, a right spring 6, a right slider 7, a support plate 8, a right bush 9, and a connecting rod 10 , mandrel 11, left cone 12, left guide plate 14, left spring 15, left slider 16, disc 17, the said mandrel 11 is suitably equipped with right nut 3, right cone 4, right Slider 5, support plate 8, right bushing 9, left cone 12, left slider 16, disc 17 and left nut 1, between described support plate 8 and disc 17 are fixedly connected by connecting rod 10, so The right slider 7 is provided with a right guide plate 5, and the right slider 7 is slidably matched with the support plate 8 through the right guide plate 5. The right slider 7 is composed of two small sliders, and the right spring is passed between the small sliders. 6 connection, a plurality of right sliders 7 are distributed along the conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com