Gas turbine blade graphene coating thin film and preparation method thereof

A technology of gas turbine blades and graphene, which is applied in the direction of coating, metal material coating process, heating inorganic powder coating, etc., and can solve the problems of insufficient service life of gas turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

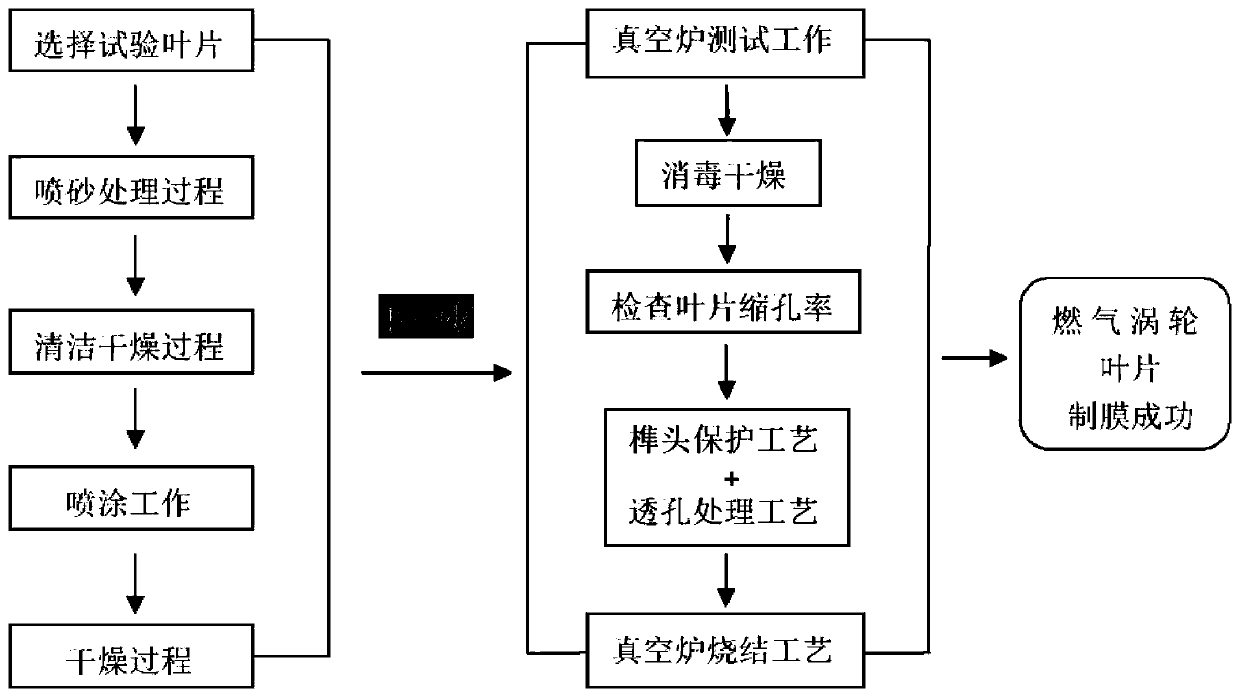

[0028] A preparation method for a gas turbine blade graphene coating film, comprising the following steps:

[0029] (1) The prepared graphene coating slurry is ball milled, and after the ball milling is completed, the graphene coating slurry is stirred evenly;

[0030] (2) Sandblasting the gas turbine blades;

[0031] (3) The gas turbine blades after sandblasting are dried with dry air, and then cleaned with chemical reagents;

[0032] (4) Carry out high-temperature disinfection and drying treatment on the cleaned gas turbine blades in a disinfection cabinet, and then carry out process optimization treatment in a drying box;

[0033] (5) Graphene coating slurry is placed in spraying equipment and stirred;

[0034] (6) Gas turbine blades are taken out from the drying box and placed on the mould, and the gas turbine blades are automatically sprayed by spraying equipment with graphene coating slurry, and the gas turbine blades after spraying are dried;

[0035] (7) The gas tur...

Embodiment 1

[0049] Check the vacuum furnace and other process equipment.

[0050] (1) The prepared graphene coating slurry is ball milled, and after two hours of ball milling, the graphene coating slurry is stirred evenly, and the slurry density is detected by a microscope, and the slurry density is ≤8.92mm;

[0051] (2) Select qualified gas turbine blades and perform sandblasting treatment, with a particle size of 80-100mm and a roughness of 2.5mm;

[0052] (3) The gas turbine blades after sandblasting are blown dry with 0.45mpa pressure dry air, and then cleaned with chemical reagents;

[0053] (4) Perform high-temperature disinfection and drying treatment on the cleaned gas turbine blades in a disinfection cabinet, and then perform one-hour process optimization treatment in a drying oven at about 150°C;

[0054] (5) The graphene coating slurry is placed on the spraying equipment and stirred, and the preparation work before the spraying operation is carried out;

[0055] (6) The gas t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com