Monolithic stopper used for continuous casting, and preparation method thereof

An integral stopper and continuous casting technology, which is applied in the field of refractory materials for steelmaking, can solve the problems of long-term continuous casting, high raw material cost, and high price, and meet the performance requirements and product quality requirements of multi-furnace continuous casting. Strong resistance to slag erosion and good thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

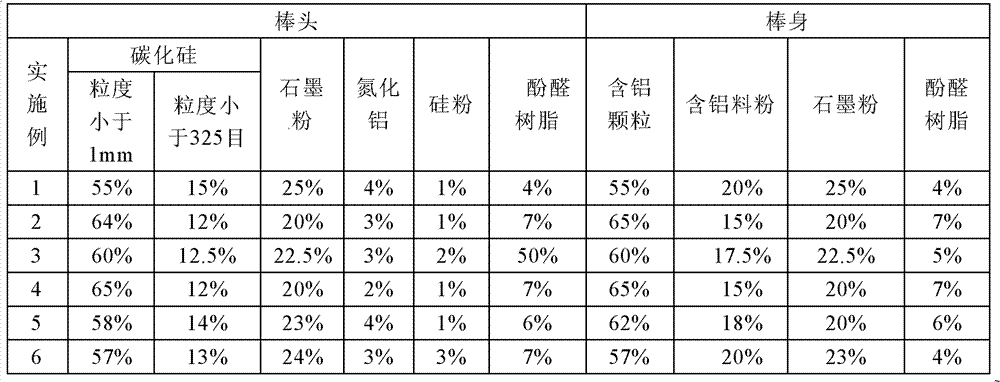

Embodiment 1

[0030] The raw materials and mass percentages used in the rod head in this embodiment are not more than 55% of 1mm SiC particles, not more than 15% of 325 mesh SiC powder, not more than 25% of 325 mesh graphite powder, not more than 325 mesh AlN powder 4%, not more than 325 mesh of AlN powder. 1% of Si powder larger than 325 mesh, plus 4% of phenolic resin; the raw materials and mass percentages used for the rod body are 55% of white corundum particles not larger than 1mm, 20% of white corundum powder not larger than 325 mesh, and graphite not larger than 325 mesh Powder 25%, plus 4% phenolic resin.

[0031] The preparation process of the integral stopper rod for continuous casting is as follows: after the raw materials of the rod head and the rod body are matched in proportion, they are mixed and granulated by a granulator, and the raw materials are dried and formed by an isostatic press. The raw material of the rod body is added to the mold twice, and the green body obtained...

Embodiment 2

[0033] The raw materials and mass percentages used in the rod head in this embodiment are not more than 64% of 1mm SiC particles, not more than 12% of 325 mesh SiC powder, not more than 20% of 325 mesh graphite powder, not more than 325 mesh AlN powder 3%, not more than 325 mesh of AlN powder. 1% of Si powder larger than 325 mesh, plus 7% of phenolic resin; the raw materials and mass percentages used for the rod body are 65% of brown corundum particles not larger than 1mm, 15% of brown corundum powder not larger than 325 mesh, and not larger than 325 mesh 20% graphite powder, plus 7% phenolic resin.

[0034] The preparation process is as follows: after mixing the raw materials of the rod head and the rod body in proportion, use a granulator to carry out mixing and granulation respectively, and after the raw materials are dried, use an isostatic press to form them, and the rod head and rod body raw materials are added in two times Mold, the compacted green body is baked in a re...

Embodiment 3

[0036] The raw materials and mass percentages used in the rod head in this embodiment are not more than 60% of 1mm SiC particles, not more than 12.5% of 325 mesh SiC powder, not more than 22.5% of 325 mesh graphite powder, not more than 325 mesh AlN powder 3%, not more than 325 mesh of SiC powder. 2% Si powder larger than 325 mesh, plus 5% phenolic resin; the raw materials and mass percentages used for the rod body are 60% of sub-white corundum particles not larger than 1mm, 17.5% of sub-white corundum powder not larger than 325 mesh, no More than 325 mesh graphite powder 22.5%, plus 5% phenolic resin.

[0037] The preparation process is as follows: after mixing the raw materials of the rod head and the rod body in proportion, use a granulator to carry out mixing and granulation respectively, and after the raw materials are dried, use an isostatic press to form them, and the rod head and rod body raw materials are added in two times Mold, the compacted green body is baked in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com