Inorganic hydrophobic antifouling glaze used for porcelain insulator as well as preparation method and application thereof

A porcelain insulator and a technology for insulators are applied in the field of improvement of glaze for porcelain insulators, which can solve the problems of poor weather resistance, low rigidity and easy aging, and achieve the effects of simple and easy preparation method, broad market prospect and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

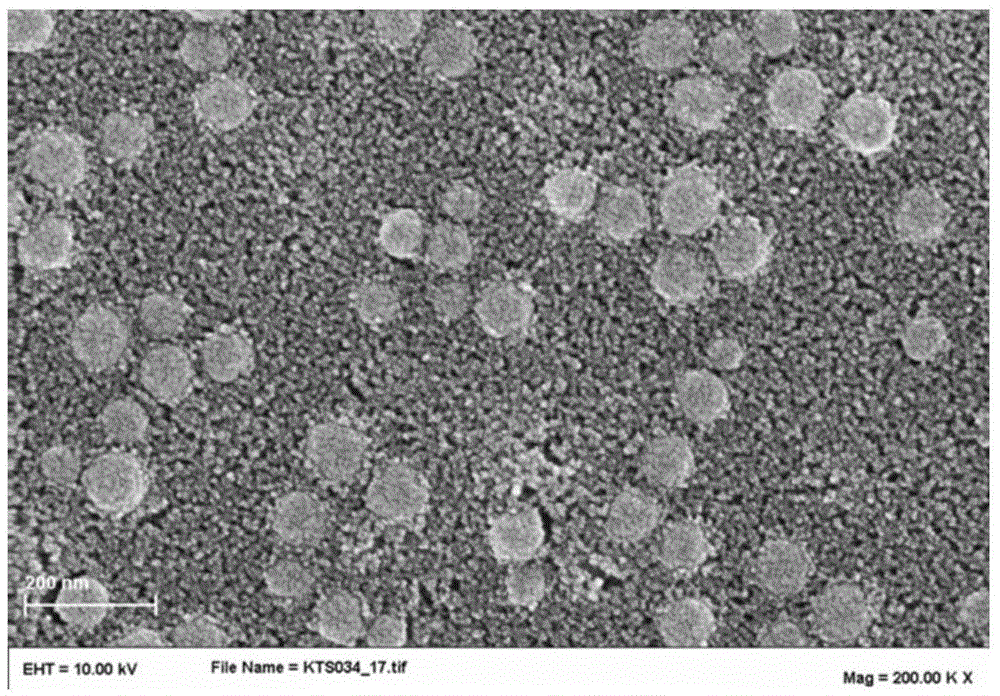

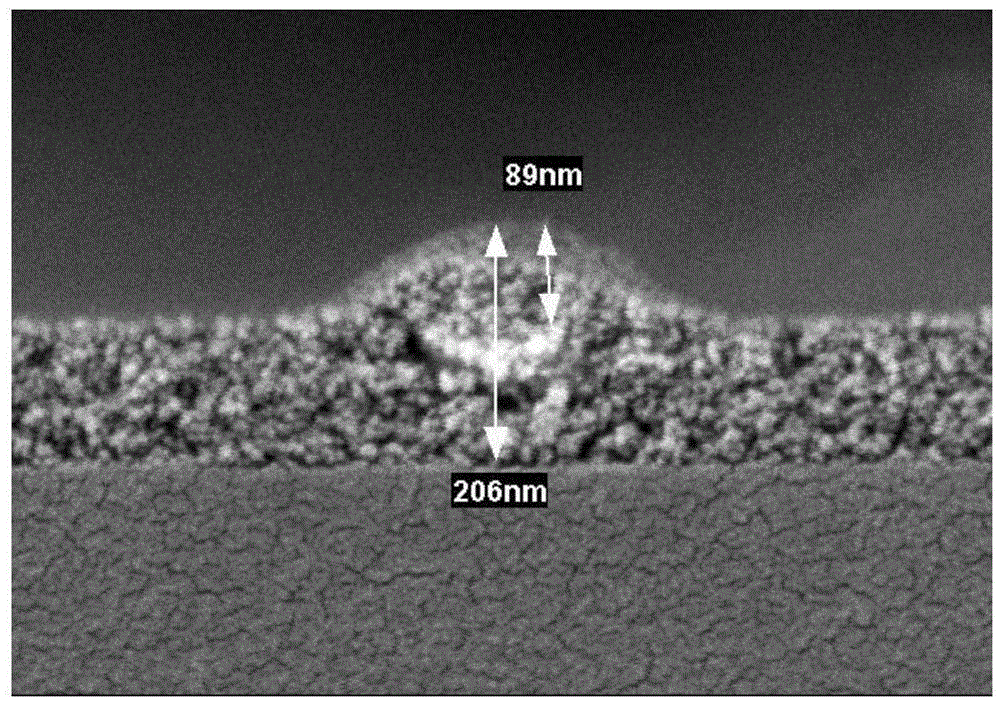

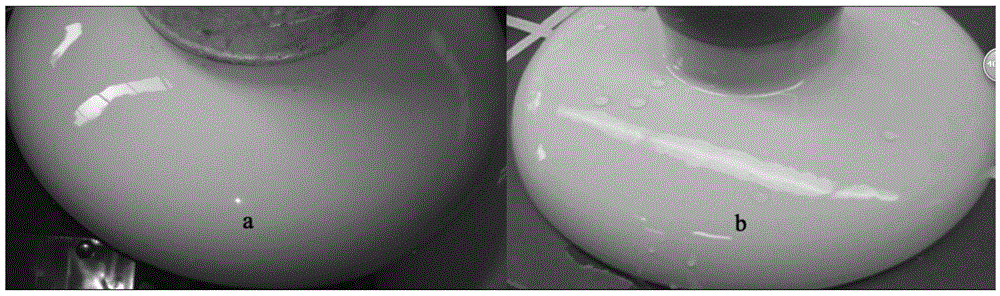

Image

Examples

Embodiment 1

[0032] (1) Preparation of coating solution

[0033] First prepare the ingredients according to the following recipe. Weigh silica sol and acetic acid respectively according to weight percentage, stir 5min on magnetic stirrer; Then add methylsilane (the mixture of methyltriethoxysilane and methyltrimethoxysilane in proportion to the stirred solution, The mixing mass ratio is 1:1), then put it on a magnetic stirrer and stir for 10 minutes; observe the uniformity of the solution, after there is no obvious precipitation or suspended matter, add propanol according to the proportion, and magnetically stir for 14 hours; the evenly stirred solution is sealed and statically It can be used after 2 days of being stale.

[0034] The glaze formulation is shown in Table 1.

[0035] Table 1 Embodiment 1 Glaze formula

[0036]

[0037] (2) Preparation of coated insulators

[0038] After the porcelain pieces come out of the kiln, blow them clean with compressed air, clean the pollutants...

Embodiment 2

[0043] (1) Preparation of coating solution

[0044] First prepare the ingredients according to the following recipe. Weigh silica sol and acetic acid respectively according to weight percentage, stir 30min on magnetic stirrer; Then add methylsilane (the mixture of methyltriethoxysilane and methyltrimethoxysilane in proportion to the solution that has been stirred, The mixing mass ratio is 1:3.5), then put it on a magnetic stirrer and stir for 50 minutes; observe the uniformity of the solution, after there is no obvious precipitation or suspended matter, add propanol according to the proportion, and magnetically stir for 12 hours; the evenly stirred solution is sealed and statically It can be used after 7 days of staleness.

[0045] The glaze formulation is shown in Table 2.

[0046] Table 2 embodiment 2 glaze formula

[0047]

[0048] (2) Preparation of coated insulators

[0049] After the porcelain pieces come out of the kiln, blow them clean with compressed air, clean...

Embodiment 3

[0054] (1) Preparation of coating solution

[0055] First prepare the ingredients according to the following recipe. Weigh silica sol and acetic acid respectively according to weight percentage, stir 10min on magnetic stirrer; Then add methylsilane (the mixture of methyltriethoxysilane and methyltrimethoxysilane in proportion to the stirred solution, The mixing mass ratio is 1:2), then put it on a magnetic stirrer and stir for 30 minutes; observe the uniformity of the solution, after there is no obvious precipitation or suspended matter, add propanol according to the proportion, and magnetically stir for 18 hours; the evenly stirred solution is sealed and statically It can be used after 5 days of staleness.

[0056] The glaze formulation is shown in Table 2.

[0057] Table 2 embodiment 2 glaze formula

[0058]

[0059] (2) Preparation of coated insulators

[0060] After the porcelain pieces come out of the kiln, blow them clean with compressed air, clean the pollutants ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com