Polyethylene composite antibacterial coating containing nanometer silver particles and preparation method thereof

A nano-silver particle and composite antibacterial technology, which is applied to coatings, biocide-containing paints, anti-corrosion coatings, etc., can solve problems that affect the protective and decorative effects of coatings, coatings lose adhesion, and biofilms spread diseases. , to achieve the effect of keeping the physical and chemical properties unchanged, high coating bonding strength and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

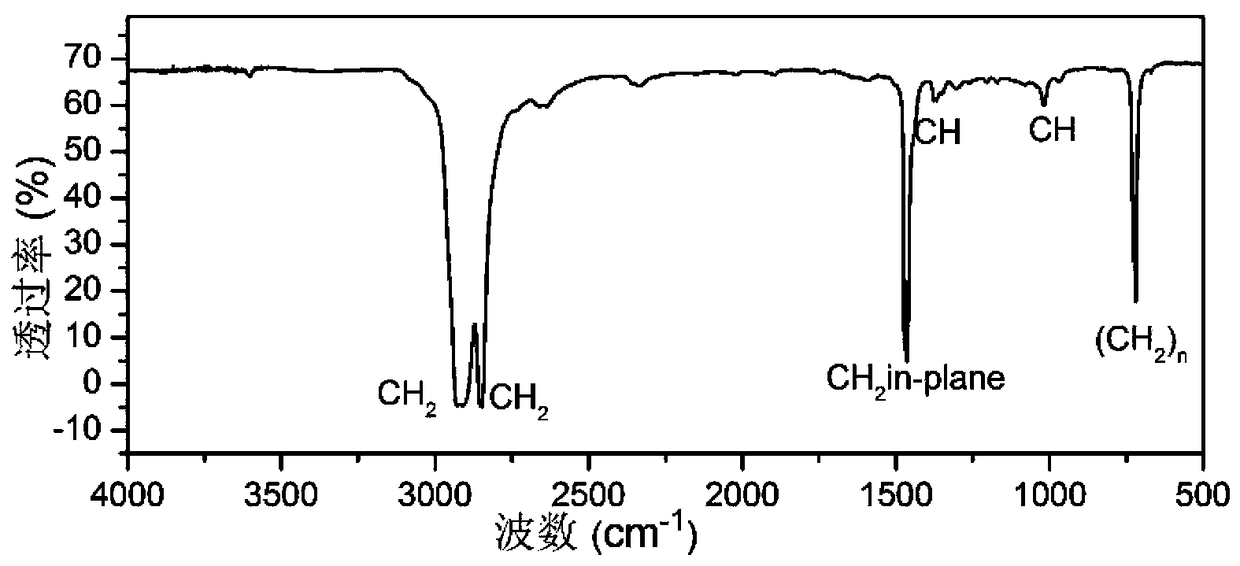

[0032] Preparation of organic solutions of polyethylene (polyethylene solutions). The polyethylene is mixed with an organic solvent at a content of 1% to 5% (the polyethylene content refers to the mass ratio of the polyethylene to the mixed paint), and placed in a heater to heat and stir until the polyethylene is dissolved. If the polyethylene content is too small, the thickness of the coating after construction will be low; if the polyethylene content is too large, the deformation of the heat-sensitive substrate will be large during the construction process, and the microstructure of the coating will be rough. The temperature of heating and stirring can be 70-90° C. until the polyethylene is dissolved. The organic solvent used can be pure xylene or toluene or both mixed solutions, because the solubility parameter (8.9 or 8.8) of xylene or toluene is close to the polyethylene solubility parameter (8.0). When the solubility parameters of the materials are similar, they can be ...

Embodiment 1

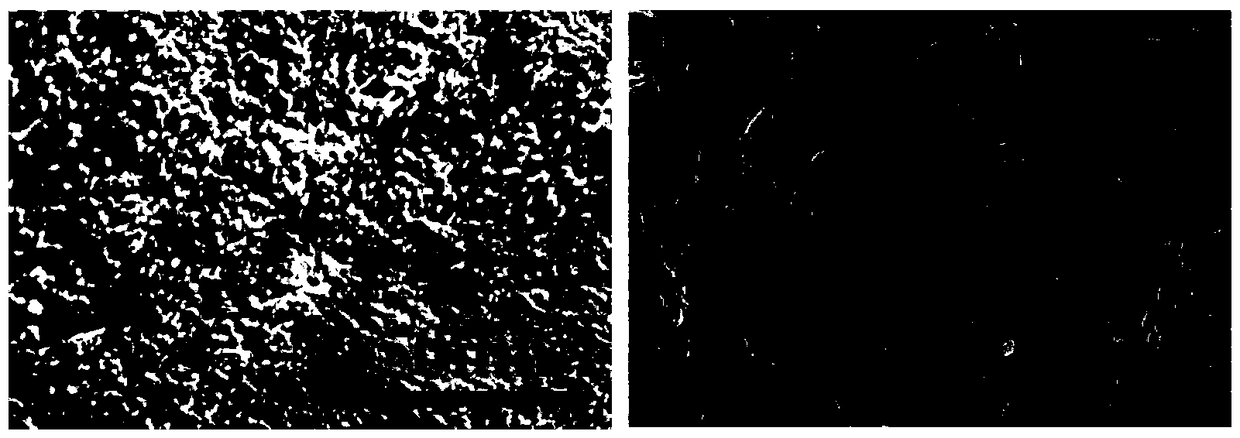

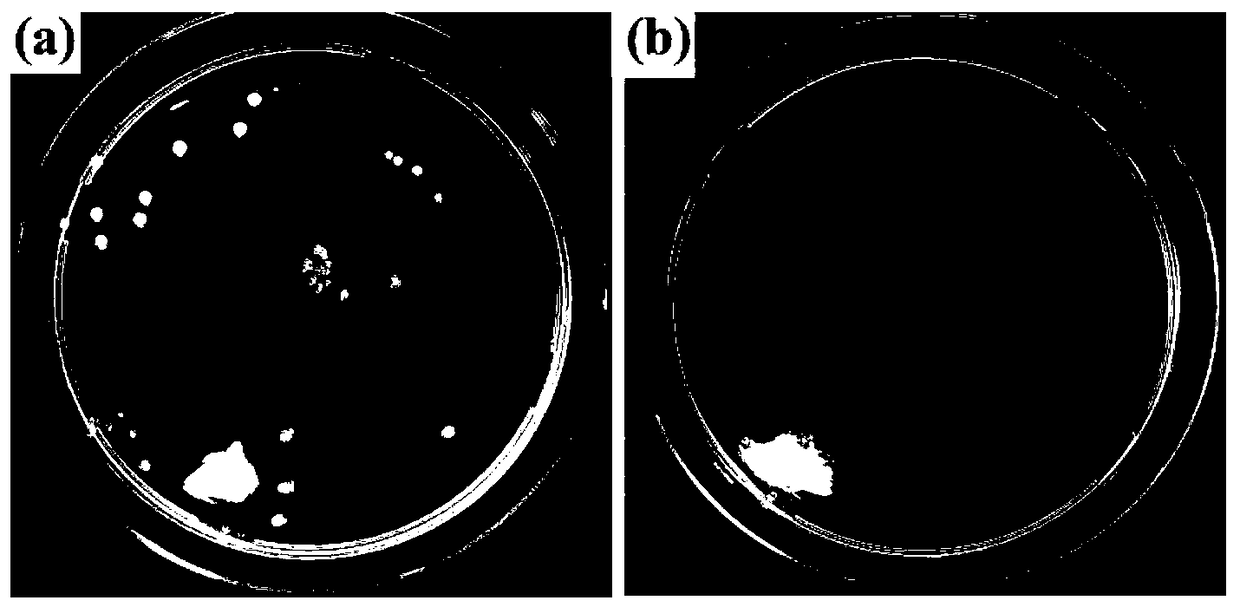

[0039] Embodiment 1: the preparation of composite antibacterial coating (MPE1-Ag10)

[0040] The polyethylene substrate was ultrasonically cleaned with absolute ethanol and deionized water for 5 minutes, rinsed with deionized water for 5 times, and dried at 30°C for 2 hours before use. Metallocene polyethylene particles (ExxonMobil, MPE 2018HA) were mixed with xylene at a content of 1%, placed in a heater at 80°C for heating and stirring continuously, until the polyethylene was dissolved, and then a certain amount of nano silver particles (particles) were weighed. The diameter is 60-120nm, Aladdin Chemical Reagent Co., Ltd., S110974), ultrasonically dispersed in the aforementioned solution, the silver content is 10ppm, and the coating is prepared. Adopt air spraying technology (the parameter of described air spraying comprises: spraying air pressure 0.24Mpa, spraying distance 15cm, the speed of moving gun 2cm / s, the paint output of mixed coating is 80ml / min) spraying coating i...

Embodiment 2

[0041] Embodiment 2: the preparation of composite antibacterial coating (MPE5-Ag300)

[0042] The polyethylene substrate was ultrasonically cleaned with absolute ethanol and deionized water for 5 minutes, rinsed with deionized water for 5 times, and dried at 30°C for 2 hours before use. Metallocene polyethylene particles (ExxonMobil, MPE 2018HA) were mixed with xylene at a content of 5%, placed in a heater at 80°C for heating and stirring continuously, until the polyethylene was dissolved, and then a certain amount of nano silver particles (particles) were weighed. The diameter is 60-120nm), ultrasonically dispersed in the aforementioned solution, the silver content is 300ppm, and the coating is prepared. Adopt air spraying technology (the parameters of described air spraying include: spraying air pressure 0.24Mpa, spraying distance 15cm, the speed of moving gun 2cm / s, the paint output of mixed coating is 80ml / min.) Spraying coating is placed on polyethylene base After the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com