Environmentally friendly high heat dissipation titanium silver white appliance backplane

A technology for home appliance backplane and titanium-silver white backcoating, which is applied in epoxy resin coating, superimposed layer plating, coating, etc. Achieve high heat dissipation efficiency, not easy to accumulate dust, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

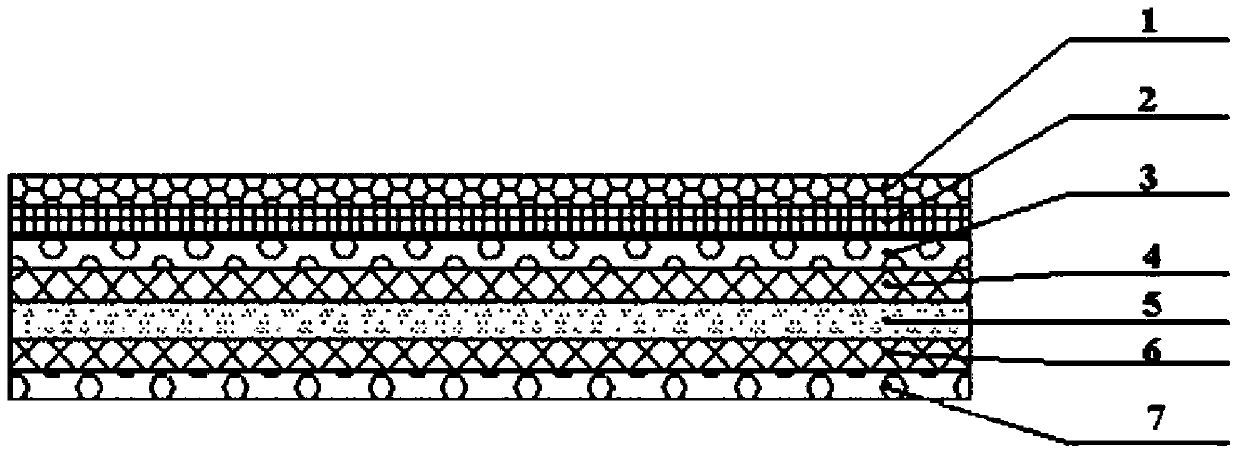

[0024] See figure 1 , The structure of the backplane of the environment-friendly high heat dissipation titanium silver white home appliance is as follows: from top to bottom, there are titanium silver white fine coating 1, heat dissipation connecting layer 2, titanium silver white pre-coating 3, first passivation layer 4, galvanized plate 5. The second passivation layer 6 and the titanium silver white back coating 7;

[0025] In the prior art, the structural design of most backplanes is basically to coat the finish coating directly on the pre-coating layer. The advantage of this is that the process is less and the cost is low, but the two layers of modified coatings are directly superimposed. It will cause the surface stress of the coating to increase. After 2-3 years of use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com