Graphene coating based on liquid material plasma spraying technology and spraying process thereof

A graphene and plasma technology, used in coatings, devices for coating liquids on surfaces, special surfaces, etc., can solve the problems of limited applicable substrates, limited preparation size, weak bonding strength, etc., and achieve high production efficiency and process flow. Simple, short production cycle results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

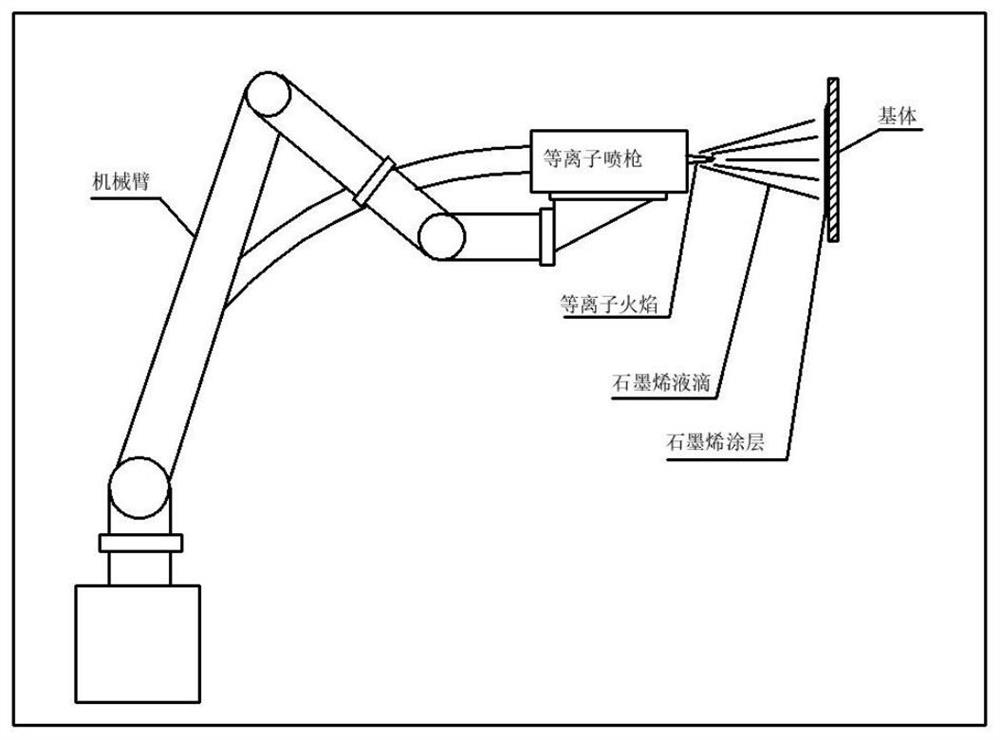

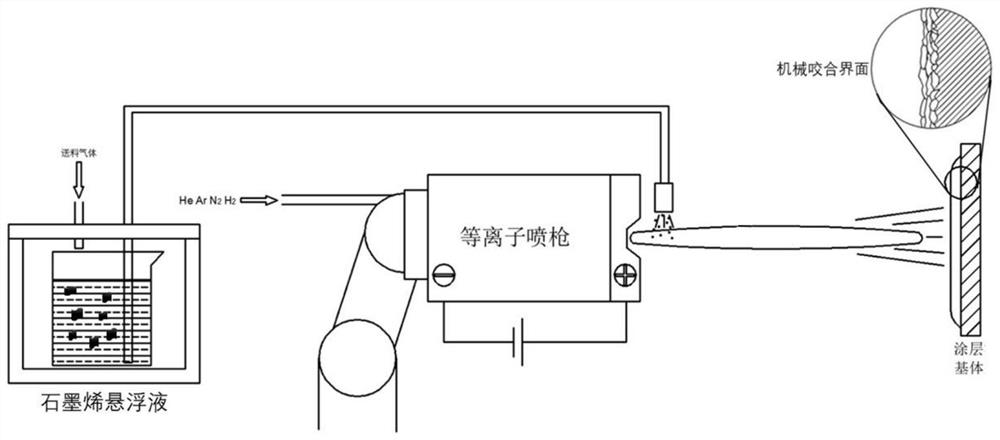

[0033] refer to Figure 1-2 Shown, a kind of graphene coating and its spraying technology based on liquid material plasma spraying technology, concrete steps are as follows:

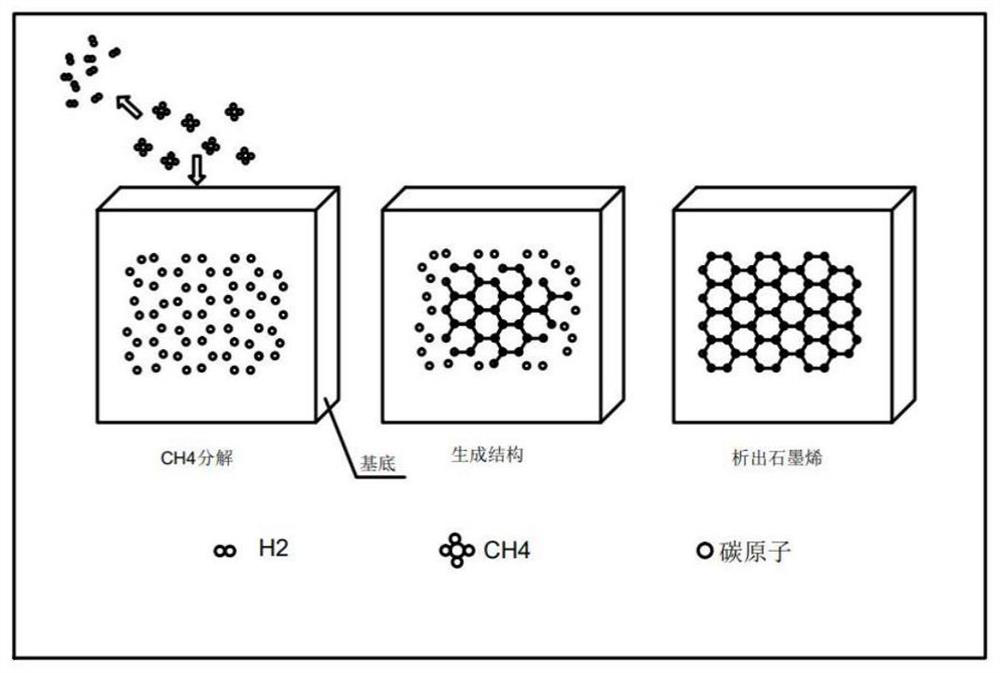

[0034] (1) Prefabricated graphene suspension: a graphite dispersion solution with a concentration of 1 mg / mL was used, and deionized water was used as a solvent.

[0035] (2) Substrate: The substrate is an alumina substrate with surface blasting treatment, the thickness is set to 1.8mm, and the substrate is preheated to 200°C.

[0036] (3) Spraying technology: set the spraying process parameters, adopt the liquid material plasma spraying technology to deposit the graphene suspension on the surface of the substrate through the spray gun, and obtain the graphene coating; realize the movement of the spray gun by setting up the plasma spray gun on the mechanical arm, and The moving speed of the mechanical arm is set at 200mm / s, the spraying distance is set at 100mm, and the number of spraying cycles is 20. ...

Embodiment 2

[0038] refer to Figure 1-2 Shown, a kind of graphene coating and its spraying technology based on liquid material plasma spraying technology, concrete steps are as follows:

[0039] (1) Prefabricated graphene suspension: a graphite dispersion solution with a concentration of 1.5 mg / mL was used, and deionized water was used as a solvent.

[0040] (2) Substrate: The substrate is a stainless steel substrate with surface sandblasting treatment, the thickness is set to 1.8mm, and the substrate is preheated to 200°C.

[0041](3) Spraying technology: set the spraying process parameters, adopt the liquid material plasma spraying technology to deposit the graphene suspension on the surface of the substrate through the spray gun, and obtain the graphene coating; realize the movement of the spray gun by setting up the plasma spray gun on the mechanical arm, and The moving speed of the mechanical arm is set at 200mm / s, the spraying distance is set at 100mm, and the number of spraying cy...

Embodiment 3

[0043] refer to Figure 1-2 Shown, a kind of graphene coating and its spraying technology based on liquid material plasma spraying technology, concrete steps are as follows:

[0044] (1) Prefabricated graphene suspension: Use a graphite dispersion solution with a concentration of 2 mg / mL and use deionized water as a solvent to compare the effect of the concentration of the prefabricated suspension on the deposition efficiency.

[0045] (2) Substrate: The substrate is an alumina substrate with surface blasting treatment, the thickness is set to 1.8mm, and the substrate is preheated to 200°C.

[0046] (3) Spraying technology: set the spraying process parameters, adopt the liquid material plasma spraying technology to deposit the graphene suspension on the surface of the substrate through the spray gun, and obtain the graphene coating; realize the movement of the spray gun by setting up the plasma spray gun on the mechanical arm, and The moving speed of the mechanical arm is set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com