Preparation method of graphene coating metal base composite powder through vapour deposition

A metal matrix composite, graphene coating technology, applied in metal processing equipment, metal material coating process, transportation and packaging, etc., can solve the problems of limited materials, decreased quality of composite powder, low output, etc., to avoid physical damage , The effect of improving material strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

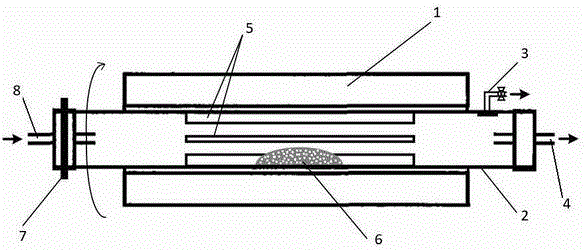

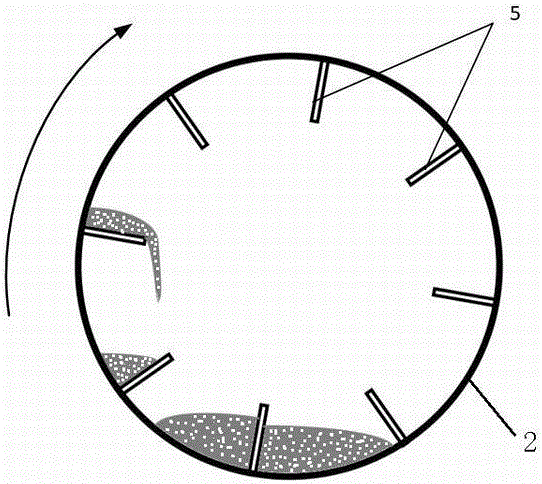

[0020] A method for preparing a graphene-coated metal matrix composite powder by vapor deposition, the specific steps are as follows:

[0021] 1. After ultrasonically cleaning 3Kg of copper powder with deionized water, ethanol, and acetone, and drying at 50 to 80°C, place the obtained copper powder in the middle of a clean quartz tube;

[0022] 2. Put the quartz tube into the tube-type electric furnace, align the middle part of the quartz tube with the middle part of the tube-type electric furnace, start heating, the heating rate is 25 ℃ per minute, pass non-oxidizing gas into the quartz tube for 60 minutes, and the air flow rate is 50 sccm , while evacuating to a suitable pressure of 10 -1 Pa;

[0023] 3. When the temperature in the middle area of the quartz tube reaches 1100-1200°C, maintain the reaction pressure, and feed carbon monoxide and acetylene into the quartz tube at 50 sccm, so that graphene begins to deposit on the surface of the copper powder;

[0024] 4. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com