Grapheme oxide-coated sulfur particle composite anode material for lithium-sulfur battery and preparation method thereof

A graphene-coated, sulfur cathode material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems that restrict the marketization of lithium-sulfur batteries, low coulombic efficiency of lithium-sulfur batteries, and poor conductivity of sulfur single substance. , to achieve high rate performance, high specific capacity, and the effect of inhibiting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

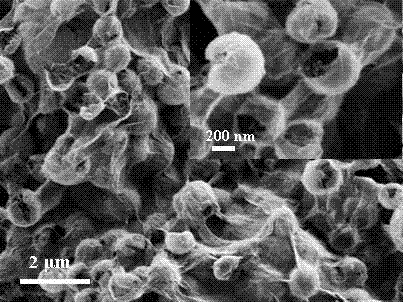

[0027] The first step: prepare 150 ml of polyvinylpyrrolidone (PVP, molecular weight 55,000) aqueous solution with a mass fraction of 3%, and stir at a speed of 500 rpm for 60 minutes; 1.5 g of sodium thiosulfate is dissolved in 5 ml of deionized water to form an aqueous solution containing Sulfur reagent aqueous solution, pour this solution into the above polyvinylpyrrolidone aqueous solution and stir at 500 rpm for 60 minutes to form a uniform solution; then slowly add 7.5 ml of hydrochloric acid aqueous solution with a concentration of 2 mol / L, and Stir at 800 rpm for 120 minutes. After the reaction is complete, the product is centrifuged and washed to obtain hollow sulfur microspheres with a particle diameter of about 500 nanometers.

[0028]Step 2: Disperse hollow sulfur microspheres into 10 ml of aqueous hydrochloric acid solution with a concentration of 2 mol / L, ultrasonicate for 15 minutes, and add 10 ml of graphite oxide with a mass concentration of 0.0005% dropwise at...

Embodiment 2

[0031] The first step: prepare 150 ml of polyvinylpyrrolidone (PVP, molecular weight 55,000) aqueous solution with a mass fraction of 0.02%, and stir at a speed of 500 rpm for 60 minutes; 1.5 g of sodium thiosulfate is dissolved in 5 ml of deionized water to form an aqueous solution containing Sulfur reagent aqueous solution, pour this solution into the above polyvinylpyrrolidone aqueous solution and stir at 500 rpm for 60 minutes to form a uniform solution; then slowly add 7.5 ml of hydrochloric acid aqueous solution with a concentration of 2 mol / L, and Stir at a speed of 500 rpm for 120 minutes. After the reaction is completed, the product is centrifuged and washed to obtain sulfur microspheres with a particle diameter of about 500 nanometers.

[0032] The second step: except that 10 ml of graphene oxide aqueous solution with a mass fraction of 0.005% is used, other operating steps are the same as in the first implementation.

[0033] The third step: the same as the first em...

Embodiment 3

[0035] Step 1: Except for using an aqueous solution of polyethylene glycol (molecular weight: 1000) with a mass concentration of 0.1%, other operating steps are the same as in Example 1. Irregular-shaped sulfur particles are thus obtained, with a particle size of 1-3 microns.

[0036] The second step: disperse the sulfur microspheres into 10 ml of aqueous hydrochloric acid solution with a concentration of 2 mol / L, ultrasonicate for 15 minutes, and add a graphene oxide aqueous solution with a mass concentration of 0.0001% dropwise at a speed of 500 rpm, After stirring for 120 minutes, let it stand for 2 hours; the product is centrifuged, cleaned and vacuum-dried (the centrifugal separation speed is 5000 rpm, and the cleaning solvent is deionized water and ethanol; the absolute vacuum degree of vacuum drying is 100Pa, and the drying temperature is 50°C, drying time is 10 hours), and finally a graphene oxide-coated sulfur microsphere composite positive electrode material is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com