Construction method of polyamide reverse osmosis composite membrane anti-pollution coating

A technology of reverse osmosis composite membrane and construction method, which is applied in the field of construction of polyamide reverse osmosis composite membrane anti-pollution coating, and can solve the problems of high operation and maintenance costs and weak anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

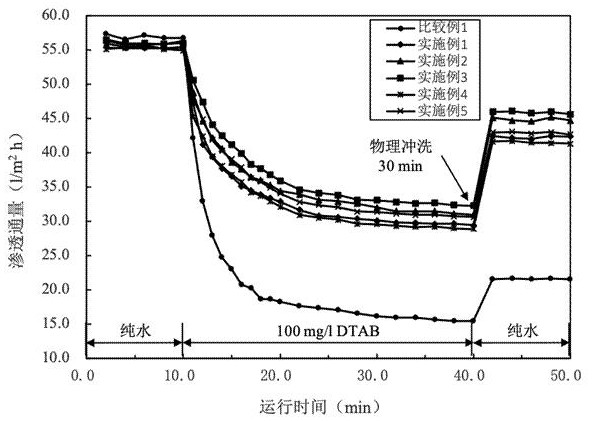

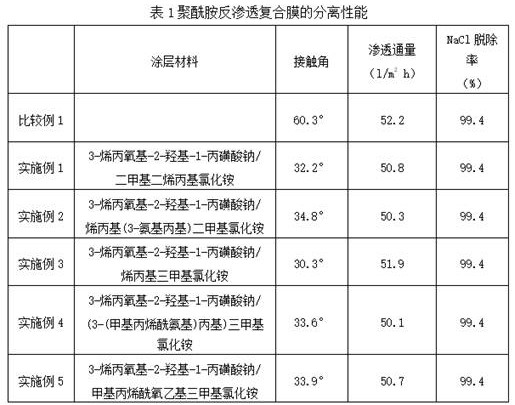

Examples

Embodiment 1

[0029] S1. Synthesis of zwitterionic functional materials:

[0030] Select 3-allyloxy-2-hydroxyl-1-propanesulfonate sodium and dimethyl diallyl ammonium chloride to mix and prepare an aqueous solution with a total mass concentration of 4.0% in a molar ratio of 1:1, and mix The solution was heated to 60 °C, and then potassium persulfate with the volume concentration of 0.8% was added to react for 5 h to obtain zwitterionic functional materials.

[0031] S2. Grafting of zwitterionic functional materials:

[0032]1) Prepare a glutaraldehyde solution with a mass concentration of 2.5%, and adjust the pH to 3.0;

[0033] 2) Prepare the above zwitterionic functional material into an aqueous solution with a mass concentration of 1.0%, and adjust the pH to 2.5-3.5;

[0034] 3) Soak the polyamide reverse osmosis composite membrane in glutaraldehyde solution for 2 minutes, take it out and wash it with pure water; then soak it in the aqueous solution of zwitterionic functional materials...

Embodiment 2

[0039] S1. Synthesis of zwitterionic functional materials:

[0040] Select 3-allyloxy-2-hydroxyl-1-propanesulfonic acid sodium, allyl (3-aminopropyl) dimethyl ammonium chloride, and mix them in a molar ratio of 1:1 so that the total mass concentration is 4.0 % aqueous solution, and the solution was heated to 60 °C, followed by adding potassium persulfate with the same volume concentration of 0.8% for 5 h to obtain zwitterionic functional materials.

[0041] S2. Grafting of zwitterionic functional materials:

[0042] 1) Prepare a glutaraldehyde solution with a mass concentration of 2.5%, and adjust the pH to 3.0;

[0043] 2) Prepare the above zwitterionic functional material into an aqueous solution with a mass concentration of 1.0%, and adjust the pH to 2.5-3.5;

[0044] 3) Soak the polyamide reverse osmosis composite membrane in glutaraldehyde solution for 2 minutes, take it out and wash it with pure water; then soak it in the aqueous solution of zwitterionic functional mat...

Embodiment 3

[0049] S1. Synthesis of zwitterionic functional materials:

[0050] Select 3-allyloxy-2-hydroxyl-1-propanesulfonate sodium and allyltrimethylammonium chloride to mix and prepare an aqueous solution with a total mass concentration of 4.0% in a molar ratio of 1:1, and mix the solution Heating to 60 °C, followed by adding potassium persulfate with the volume concentration of 0.8% for 5 h to obtain zwitterionic functional materials.

[0051] S2. Grafting of zwitterionic functional materials:

[0052] 1) Prepare a glutaraldehyde solution with a mass concentration of 2.5%, and adjust the pH to 3.0;

[0053] 2) Prepare the above zwitterionic functional material into an aqueous solution with a mass concentration of 1.0%, and adjust the pH to 2.5-3.5;

[0054] 3) Soak the polyamide reverse osmosis composite membrane in glutaraldehyde solution for 2 minutes, take it out and wash it with pure water; then soak it in the aqueous solution of zwitterionic functional materials for 8 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com