Laser method for repairing rotor shaft of generator and steam turbine and dedicated device

A steam turbine rotor and laser repair technology, which is applied to the repair of steam turbine rotor shafts and generators, can solve the problems of lack of mobile practicability, inconvenient installation and debugging, complex structure, etc. Repair cycle, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

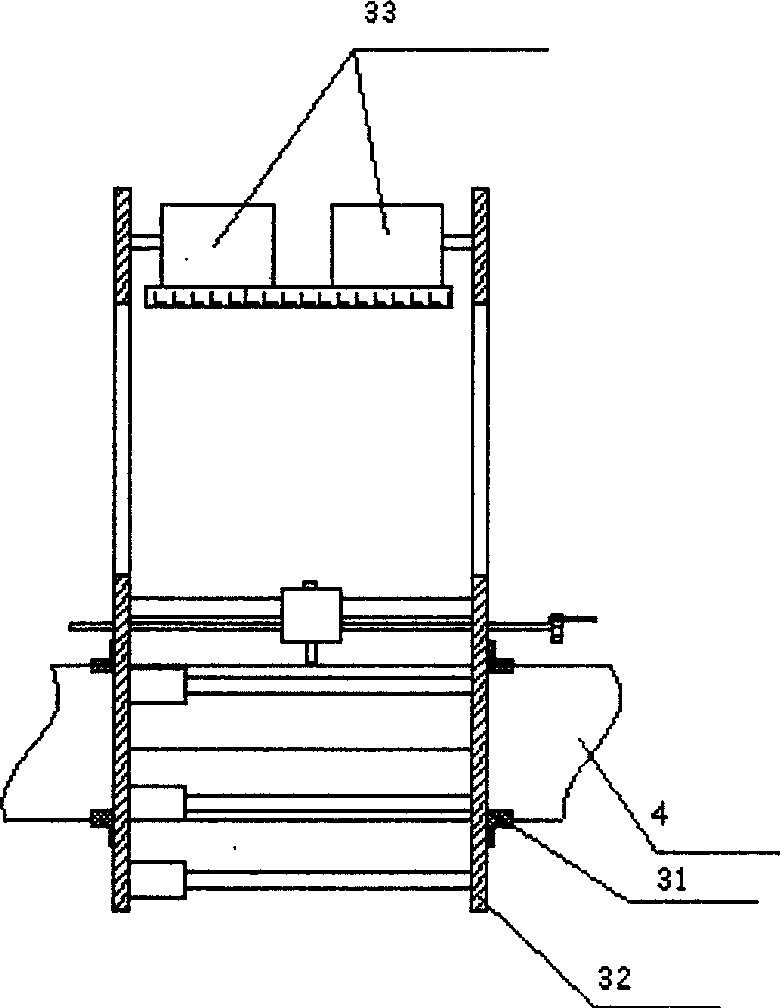

[0038] Embodiment Modular laser processing machine and rotor shaft conformal processing equipment

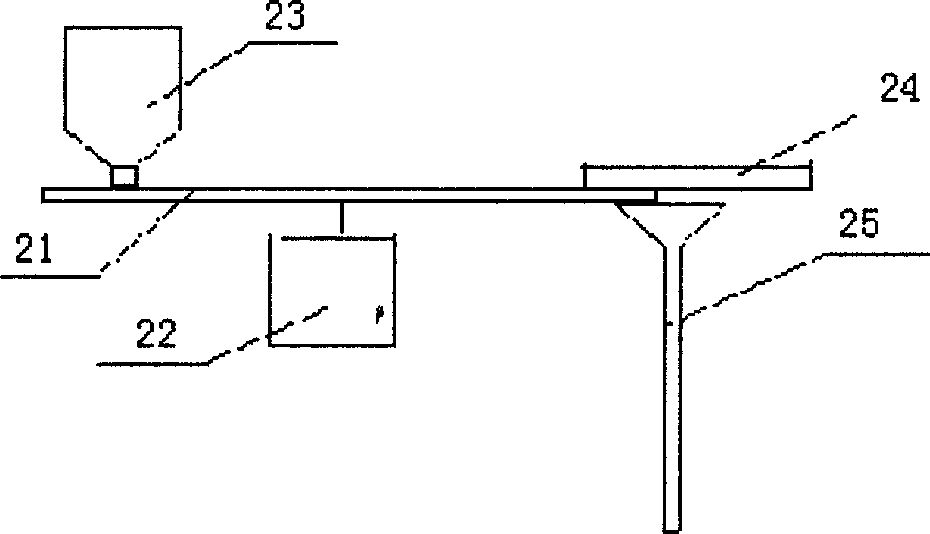

[0039] The modular laser processing machine consists of a laser generator (11), a laser processing machine, an automatic powder feeder, and a stepless speed regulation mechanism:

[0040] The design of the cooling system of the laser generator (11) adopts open water cooling, the inlet is connected to the on-site water source, and the outlet is directly discharged;

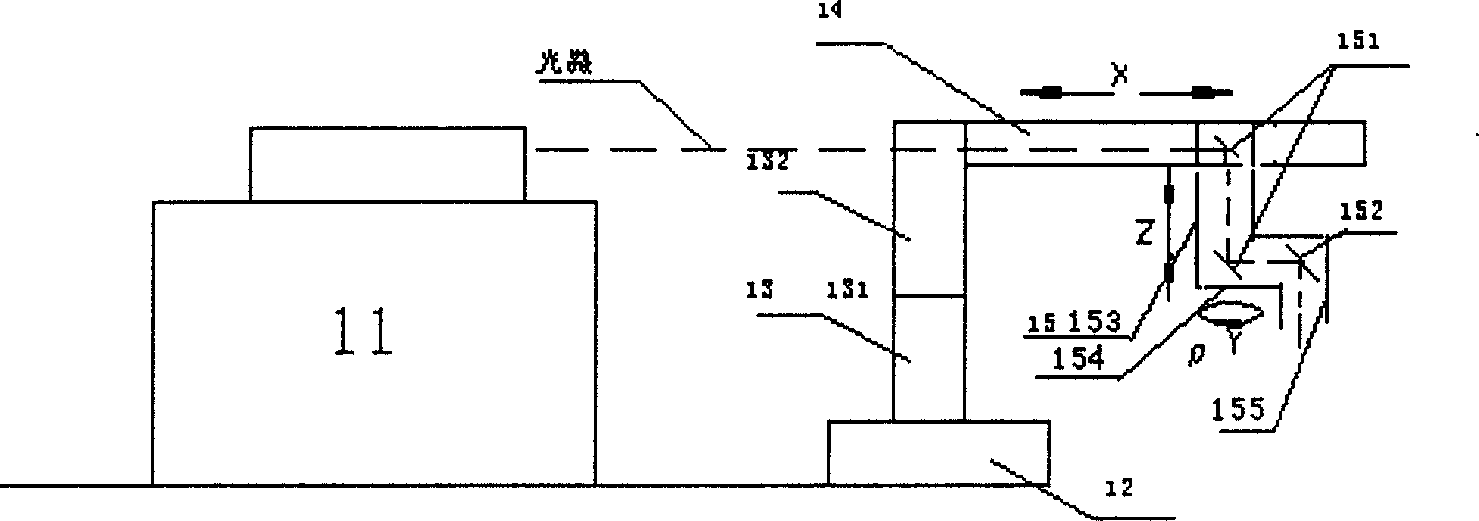

[0041] Laser processing machines (such as figure 1 Shown) is made of base (12), first-level column (131), secondary column (132), crossbeam (14), combined lens barrel (15), and combined lens barrel (15) is made of vertical lens barrel (153), The horizontal lens barrel (154) is actively connected with the vertical telescopic lens barrel (155), and the reflector (151) and focusing mirror (152) arranged in the crossbeam (14) and the combined lens barrel (15) constitute the optical path.

[0042]The vertical telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com